Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: Fox Chapel Publishing

- Kategorie: Lebensstil

- Sprache: Englisch

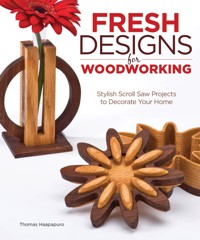

Awaken your modern design aesthetic with 21 striking contemporary designs for thehome. The fusion of nature's elegant shapes and modern architecture's bold symmetry yeilds a dynamic and engaging collection of designs for scroll saw woodworking.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 159

Veröffentlichungsjahr: 2018

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

ABOUT THE AUTHOR

Thomas Haapapuro is an accomplished woodworker, sculptor, and designer. Growing up in the foothills of the Appalachian Mountains, Haapapuro was exposed to the subtle beauty found in nature, a theme that can be seen throughout his work.

After graduating from The Ohio State University with a Bachelor of Science degree in Landscape Architecture, Haapapuro worked professionally for ten years designing rooftop gardens, urban courtyards, and site-specific art pieces. He has also been a woodworker for the past eight years. Using these skills, Haapapuro creates objects that distill the intricate and complex patterns of nature into clean, sophisticated, and modern forms. In addition, his artwork is made solely from salvaged trees in his local area of Charlotte, North Carolina.

Haapapuro is a contributor to Scroll Saw Woodworking & Crafts magazine and is represented by several galleries throughout the southeastern United States. Through his company, THaap Designs, he produces wood sculptures, bowls, boxes, jewelry, furnishings, toys, wall plaques, and concrete sculptures, fountains, and planters. To learn more, visit www.thaapdesigns.com.

INTRODUCTION

In addition to providing a collection of interesting patterns, I want this book to be used as a learning workbook for woodworkers of any skill level. With this book, the beginner can learn how to use the scroll saw and gain knowledge of its basic use, while more experienced scrollers can learn and master additional skills and techniques. The projects are arranged to progress from beginner to advanced with the initial projects introducing fundamental cutting techniques that are reinforced and built upon in the subsequent chapters. Additional skills and techniques are introduced and reinforced with projects that guide you through the process and emphasize the new skills. By the end of this book, you will have gained a solid understanding of the scroll saw’s use and potential as a tool for creating unique and beautiful works of art.

This book is also meant to teach you how to design your own scroll saw projects. A brief description accompanies most projects, explaining how I developed the pattern for that particular piece. The final portion of the Getting Started section delves a little deeper, explaining processes, tools, and software that assist designers in developing new scroll saw patterns and techniques (see page 8).

I hope you enjoy discovering all the scroll saw has to offer.

—Thomas Haapapuro

CONTENTS

INTRODUCTION

GETTING STARTED

CHAPTER 1: BEGINNER PROJECTS & TECHNIQUES

Radial Symmetry Trivet

Tree Forms

Linguine Décor

Farm Fields

Linguine Forms

CHAPTER 2: INTERMEDIATE PROJECTS & TECHNIQUES

Leaf Forms

Leaf Array

Floral Essence

Floral Time

Radial Squares

Asymmetric

Circular Void

Geometrix

Bubbling Up

CHAPTER 3: ADVANCED PROJECTS & TECHNIQUES

Arabian

Elliptical Array

Chinese Lattice

Seed Pods

Rectilinear Spirals

60° Repetition

Simple Balance

INDEX

GETTING STARTED

The purpose of this book is to teach you the essential skills and techniques you need to make any desired project, and even design your own patterns. Before you start with the projects, though, there are some things you need to know. This section covers the basics of the equipment, tools, and materials you’ll use throughout the book and will prepare you to start making your own nature-inspired creations.

CHOOSING A SCROLL SAW

Choosing a scroll saw can be as daunting a task as buying any piece of woodworking equipment. The price ranges dramatically from as low as one hundred dollars to several hundred dollars. Much like buying a car, any scroll saw will get you where you are going, but the ride in the expensive models is much more comfortable than in the less expensive ones. With scroll saws, the difference in price is largely a matter of ease of use. More expensive models have features that make many tasks easier, but they are not essential to creating beautiful woodworking projects. You don’t need great tools to produce great work. The most basic of scroll saws will work for all of the projects presented here. There are several books on the market that offer detailed information about different saws and provide specific information about the pros and cons of each. I will not go to such a level of detail here, but I will give a quick overview of the key items you will want in a saw.

Vibration is one of the key differences between saws. Inexpensive models are often made of steel with aluminum tables. This make the saws less expensive for the manufacturer to produce and ship, but does little to absorb their motion. Expensive models feature cast-iron bodies and steel tables. These more robust saws absorb most of the vibration, making smooth cuts easier to accomplish. (For comparison, think of trying to draw a straight line with a pencil on a piece of paper placed on top of a cheap washing machine that bounces and vibrates.)

Another item that varies from saw to saw is the throat clearance and depth. This is an important feature, and the bigger you can afford, the bigger you should buy. Like anything else, you will not necessarily need the extra clearance now, but it’s better, if you can afford it, to purchase a saw with a throat clearance and depth beyond what you expect to cut currently than to have to replace the tool later on because it is too small for future projects. That said, all the projects in this book were made using a very simple saw with a throat clearance of just 3" (76mm) and a throat depth of 16" (406mm). Many of the projects in the book are fairly large, however, and in some cases I had to cut several access holes in one waste area because the throat depth was too short to allow me to swing the workpiece. Again, a smaller saw will work, but a bigger saw makes the work easier.

Blade changes are another item to consider. On a scroll saw, there are two blade clamps: one on the bottom and one on the top. The bottom clamp is only used when changing a blade, which, as most projects can be completed with only one or two different kinds of blades, doesn’t happen that frequently. The top blade clamp is used much more frequently, as it is this clamp that is released to feed the blade through access holes in the workpiece. Most saws use thumbscrews to tighten the top and bottom blade clamps. Many people find using thumbscrews is a simple way to change and adjust blades. Personally, I dislike them, as it is hard for my large hands to access the screws on the bottom, and I find it difficult to tighten the clamps enough so the blades do not pull free when making cuts in thicker wood. For readers with a similar mindset, there are alternative options to thumbscrews. Many saws use a tool to tighten the bottom clamp, which can be helpful in that cramped area. Some saws use a quick clamp system on the top clamp, which really speeds up the blade release process. If your preferred saw does not come with a quick clamp, they can be purchased individually for a wide variety of saws from www.wildwooddesigns.com.

Variable speed is an essential item on a scroll saw. This is a feature available on most saws, so you should have no trouble finding a saw with it. When cutting fine patterns from thin stock, slowing the speed down allows you more time to trace the pattern, minimizing mistakes. When cutting thick stock or rip sawing, the ability to turn up the speed on the saw significantly shortens the time needed for this otherwise slow and plodding task.

My scroll saw

As mentioned earlier, you don’t have to have great tools to make great work. I still use the first scroll saw I ever purchased almost ten years ago. It is a Delta 16" (406mm) variable-speed scroll saw, model #40-540. It has a solid cast-iron base and a machined steel table that minimizes the vibration. Its vertical blade clearance is 2 ⅝" (67mm) with the hold-down arm removed, allowing for taller workpieces to be cut. The bottom blade clamp is loosened with a specialty tool that is quite easy to use during full blade changes, while the top blade holder is a quick clamp mechanism.

This is the scroll saw I use, but you can select the brand or model that suits your desires or price range, as long as you remember to take into consideration the items listed previously.

Blade selection

When I first purchased my scroll saw, I went to my local woodworking store to buy blades. I was a little daunted as I stood staring at the wall filled with dozens and dozens of saw blades. As a novice, it can be difficult to determine which blades are best for the various materials you will be cutting. The variety of blades available should not overwhelm you, but rather excite you. This vast number of blades means we are capable of cutting a wide variety of materials. You can purchase blades that cut wood, nonferrous metals, and acrylics. For the beginner, and particularly for the projects in this book, you will want to use blades designed for cutting wood.

Depending upon the type of saw you own, you will need to purchase either pin-end or straight-end blades. Straight-end blades are more popular than pin-end ones, so you’ll often find a larger selection of straight-end blades available at your local woodworking store. The disadvantage of pin-end blades is that regardless of the size of the blade you are using, you still have to thread the rather large pin end through the woodwork. This is not a problem for projects with large waste areas (like wall plaques) where a large access hole will not make a difference, but for most projects, a small pilot hole is essential to the construction. So while there are many types of saws available, using a saw that accepts plain-end blades will offer the most flexibility for the widest variety of projects.

The differences among wood cutting blades are largely a matter of beam strength (stiffness of the blade) and tooth arrangement. Generally, a blade with more teeth per inch (tpi) cuts slowly and produces a smooth cut. Blades with fewer teeth make faster, rougher cuts.

As mentioned previously, you can find a huge variety of scroll saw blades, but you will need only a handful for the projects in this book. The following is a list of the different blades I used to create the projects. I’ve provided my thoughts on the pros and cons of each blade. As you purchase and experiment with different blades, you will find the ones you prefer to work with and the ones that work best with the materials you like to cut.

Standard-tooth blade. For many years, this was the only type of blade available. It’s a very straightforward blade and a good scroll saw workhorse. Unlike many of the blades that follow, the teeth on this blade all run the same direction.

•Pros: This blade is often thicker than others, with greater beam strength. It’s able to withstand heavy tension and less likely to bulge or burn when cutting thick wood.

•Cons: Standard blades tend to leave fuzz on the bottom of a cut, which must be sanded off afterward.

Skip-tooth blade. Like the standard blade, the teeth on a skip-tooth blade all run in the same direction. As the name implies, however, alternating teeth from the blade have been omitted. This allows the blade to remove sawdust more easily, which keeps the blade cooler. The omitted teeth also make this a faster cutting blade than a standard-tooth blade.

•Pros: A skip-tooth blade has no offset in the teeth, allowing for narrower cuts. The gap in the tooth alignment clears away sawdust more efficiently than other blades, keeping the blade cool and allowing for faster cuts.

•Cons: Like the standard blade, the teeth of a skip-tooth blade run in the same direction, leaving fuzz on the bottom of a cut.

Reverse-tooth blade. The reverse-tooth blade has many of the same characteristics as the skip-tooth blade; however, the teeth at the bottom of the blade have been reversed (i.e., point upward). This design feature was added to minimize the fuzz and tear out associated with both the skip-tooth and standard-tooth blades.

•Pros: The reversed teeth at the bottom of the blade cut upward, minimizing tear out and fuzz at the bottom of the cut.

•Cons: Without the staggered teeth of a skip-tooth blade, these blades tend to cut more slowly.

Crown-tooth blade. On reverse-tooth blades, the reversed teeth are located only at the bottom of the blade. If you don’t adjust the blade so the reverse teeth extend beyond the top of a cut on the saw’s return stroke, you may encounter tear out and fuzz, especially when working with fragile materials like plywood and oak. The solution to this problem is the crown-tooth blade, which has teeth that alternate pointing upward and downward. This ensures a smooth cut at all times. Since the teeth cut on the upstroke and downstroke, the blade is also more efficient than those listed previously.

•Pros: A crown-tooth blade produces a smooth finish, as the teeth cut on both the upstroke and the downstroke. It is a great choice for cutting plastic, which tends to melt with too much friction and chip out when cut with standard-tooth blades.

•Cons: This is often a narrow blade with less beam strength. I have also found these blades to be slower than most of the others available.

Spiral blade. A spiral blade is a standard blade that has been twisted into a corkscrew shape. This means it constantly cuts on all sides, allowing you to cut out shapes without turning the workpiece. This may sound enticing, but there are some serious drawbacks to these blades. Because the blade is twisted, the width of the cut (kerf) is far wider than any of the other blades. This blade also tends to chew up the wood, leaving fuzz and tear out on both sides of the cut. You should really only use this blade when the throat of your saw will not allow you to make a cut with a different kind of blade.

•Pros: Very large pieces of wood can be cut on the scroll saw with this blade, as the workpiece does not need to be rotated to make the cuts.

•Cons: This blade produces very rough finished edges with tear out and fuzz. Also, the kerf of the cut is far wider than any other kind of blade available.

In the end, blade selection is really a personal choice. Some blades are more ideally suited for particular tasks. As you experiment and start working on projects, however, you will find you tend to rely on one kind of blade as your everyday blade.

When I stood in that woodworking store, looking at all of the blades available to me for the first time, I used a reference similar to the one I’ve given you to select a variety of blades: standard-tooth blades, skip-tooth blades, reverse-tooth blades, and even a set of spiral blades. The spiral blades were just as horrible as I had read, and I have not used them since then. As most of my work involves cutting thick wood, I actually rely on a few different sizes of skip-tooth blades for almost all my pieces. For some of the plywood projects where tear out was a concern, I used reverse-tooth blades for a smooth cut. I use Craftsman blades, available at Sears and other similar locations. I like these blades more than others I have tried because they are tough. Their high beam strength and stiff steel construction makes them less likely to burn, warp, or bulge in cuts. They do heat up in heavy cuts and do not clear sawdust very well. I have tried blades from other manufacturers that were designed for thick wood. These were fast blades with large hooked teeth that removed material efficiently but were very hard to control and tended to bulge in the cut far more frequently. My solution is to use the Sears blades for their durability and control and to be patient and move slowly to allow the blade to do the work. Just because I use these blades, however, does not mean you have to use them. Try several different kinds of blades from different manufacturers. Like most things in life, you can read my advice and try the blades I like, but ultimately the final decision about which blades you use will be a matter of your personal taste and preference.

OTHER TOOLS

In addition to my scroll saw, there are a handful of tools I use to make my work easier. You will also find them beneficial as you create projects.

Sharpened putty knife. This simple tool is one I rely on often. It is useful for separating re-sawn wood, pieces of wood attached with double-sided tape, and even for scraping excess spray glue from the workpiece prior to sanding. While a standard putty knife will work, adding a sharp edge to this tool makes it thinner and causes it to leave little to no damage on wood pieces when prying them apart.

To sharpen a putty knife, pick a sturdy, metal putty knife in a width to suit your preference (mine is a 3" [75mm] knife, so I can distribute the pressure of prying over a wider surface.) To sharpen the end, use a bench-top grinding stone to gently thin the blade on both sides until you reach the desired sharpness. In a pinch, you can also sharpen the knife using a belt sander, but this will decidedly shorten the life of your sanding belt.

Double-sided tape. Double-sided tape is a valuable tool for the scroll saw artist. It is indispensable when stack cutting. While there are other ways to temporarily hold wood together for stack cutting, including screwing the boards together in waste material areas or stapling or taping the ends of the boards together, double-sided tape keeps all the wood pieces together as you make your cuts. After cutting, the pieces can be gently pried apart using a sharpened putty knife as mentioned earlier. Note: Not all double-sided tapes are created equally. The stuff you can get at big box stores is generally not appropriate for woodworking. I’ve found the tape that works best is a paper-style tape available at most specialty woodworking stores. If your local store does not carry quality tape, you can purchase it online at Klingspor Woodworking Shop (www.klingsporwoodworkingshop.com).

Spray adhesive. Spray adhesive is an indispensable tool for the scroll saw artist. With it, you can attach a pattern directly to a piece of wood for cutting. If you use a temporary spray adhesive, such as that made by Duro, you can safely remove a pattern from the wood by gently pulling it off when your work is complete. Some light sanding will remove any residue left on the wood after the pattern is removed. To attach a pattern with spray adhesive, spray the pattern, not the wood. Spraying the adhesive onto the wood allows it to be absorbed into the wood’s pores, which makes removing the adhesive residue more difficult. Spray the back of the pattern thoroughly, and then let it air-dry for 15–30 seconds. This allows the adhesive to set and become tacky and will make it easier to remove the pattern from the workpiece later.