Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: Fox Chapel Publishing

- Kategorie: Lebensstil

- Sprache: Englisch

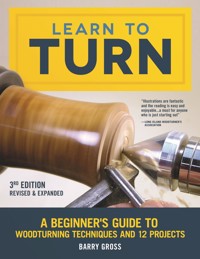

Learn to Turn is the ideal woodturning book for beginners. If you've considered trying woodturning—but have been intimidated by the tone and scope of the books available on the subject—you'll find this informative book to be an approachable and enjoyable guide that will have you turning in no time. Author Barry Gross, an artist and professional woodturner, offers expert instruction, valuable tips, and common-sense advice that will eliminate the mystery while infusing some fun into your turning. Discover how to select the lathe that's right for you, the basics of turning tools, and the fundamentals of sharpening, sanding, and finishing. This revised & expanded 3rd edition also includes new and very attainable step-by-step projects, a special troubleshooting section that reveals surprisingly simple solutions to common turning mistakes, and an inspiring artist gallery of completed works.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 160

Veröffentlichungsjahr: 2021

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

DEDICATION

Writing a book on woodturning takes a long time away from your family, and I am blessed with a wife and family who understand the time constraints needed to fulfill that obligation. Thank you, Lenora (my best friend), who assists, guides, and offers a unique perspective to this obsession I have with turning!

© 2018 by Barry Gross and Fox Chapel Publishing Company, Inc., 903 Square Street, Mount Joy, PA 17552.

Learn to Turn, Revised & Expanded 3rd Edition is a revised and expanded edition of Learn to Turn, 2nd Edition Revised and Expanded, first published in 2013 by Fox Chapel Publishing Company, Inc. The patterns contained herein are copyrighted by the author. Readers may make copies of these patterns for personal use. The patterns themselves, however, are not to be duplicated for resale or distribution under any circumstances. Any such copying is a violation of copyright law.

Print ISBN 978-1-56523-928-9eISBN 978-1-60765-502-2

The Cataloging-in-Publication Data is on file with the Library of Congress.

To learn more about the other great books from Fox Chapel Publishing, or to find a retailer near you, call toll-free 800-457-9112 or visit us at www.FoxChapelPublishing.com.

We are always looking for talented authors. To submit an idea, please send a brief inquiry [email protected].

Because working with lathes, wood, and other materials inherently includes the risk of injury and damage, this book cannot guarantee that creating the projects in this book is safe for everyone. For this reason, this book is sold without warranties or guarantees of any kind, expressed or implied, and the publisher and the author disclaim any liability for any injuries, losses, or damages caused in any way by the content of this book or the reader’s use of the tools needed to complete the projects presented here. The publisher and the author urge all readers to thoroughly review each project and to understand the use of all tools before beginning any project.

ABOUT THE AUTHOR

Barry Gross’s love of woodworking started as a child, when he would build “boats” out of 2x4s and nails and then try to float them in the bay (unsuccessfully). He purchased his first lathe at the age of 15 and started to turn small spindles with little success because there was no real instruction available. There were no DVDs or turning clubs to advise him as there are today. Later on, however, Barry returned to woodworking and the lathe to create pieces of furniture. It was not until he received a lesson on pen making that his love of turning solidified. He has turned thousands of pens and small turnings using all types of materials. His pens have been purchased by the White House to give as gifts for foreign dignitaries, and many celebrities have purchased his fine writing instruments.

Barry also belongs to a number of turning clubs and is a member of the American Association of Woodturners, where he has demonstrated at their national symposiums. He demonstrates his unique brand of pen making at turning clubs and woodworking shows throughout the country. For the past few years, Barry has been teaching at Arrowmont School of Arts & Crafts and Marc Adams School of Woodworking. In addition to authoring five turning books, he has released two DVDs on pen making and published over 70 articles in various woodworking magazines, including Woodturning Design and Fine Woodworking. In August 2012, he purchased woodturning supply company Arizona Silhouette and combined it with his own BG Artforms LLC to form a larger company that offers turning supplies worldwide.

ACKNOWLEDGMENTS

First, I want to thank Alan Giagnocavo, Peg Couch, Gretchen Bacon, and the rest of the Fox Family for giving me the opportunity to produce another book on turning for Fox Chapel Publishing. Thanks elso to Greg Heisey and Scott Kriner for photography.

For the finer points of turning, my friend Ed Ryan has been magnanimously offering his advice and guidance to me for years. I give full credit to Ed for showing me as well as hundreds of other turners the “ABC’s” of tool control. Whenever instructing students, using the “Ed Ryan” method always makes the subject of tool control much easier for students to comprehend.

The following companies and individuals, listed alphabetically, have either provided tools, supplies, or invaluable advice, and I want to thank them for their time and patience in assisting me with my questions.

• Arizona Silhouette

• Berea Hardwoods—Jim Heusinger

• BG Artforms

• Craft Supplies USA—Rex Burnham

• Ironclad Performance Wear—Kyle Jochai

• New Edge Cutting Tools—Fred Smith

• Oneway Manufacturing—Stephen Feringa

• Packard Woodworks—Brad Packard

• Penn State Industries—Ed Levy, Mark Schwartz

• Robert Sorby Turning Tools—Robert Walton

• RPM Wood Finishes Group (Behlen Finishing Products)

• Trend Airshield and Trend Air Ace—Terry Cole

• Triton Powered Respirator—Mark Owen

• Woodcraft Corporation—Ben Bice

CONTENTS

INTRODUCTION

1: GETTING STARTED

Safety

Basic Workshop and Tools

Choosing Wood

Sharpening Tools

Sanding

Finishing

2: START TURNING

Getting Ready to Turn

Turning Tool Exercises

Spindle Turning Projects

Faceplate Turning Projects

Spindle and Faceplate Projects

Troubleshooting

3: MARKETING AND SELLING YOUR WORK

4: GALLERY

GLOSSARY

INTRODUCTION

So much has been written about woodturning in the past that it creates a challenge to approach the topic with an innovative agenda. My method is to look at woodturning from the perspective of the student and not the teacher. Looking at woodturning from this viewpoint brings to light some of the frustrating aspects of the hobby as a beginner—such as feeling nervous when you first try to turn a piece of wood on a lathe; struggling to grind an edge on a tool; attempting to get a good finish on a bowl; or turning the final bead on a spindle, getting a “catch,” and demolishing your project. I can identify with these and other apprehensions because I did them. Any experienced turner will tell you that we all make mistakes and that practice working at a particular skill is all it takes for the mistakes to correct themselves. However, by identifying some common problems and offering tips to overcome these issues, the hobby will become more enjoyable and some of the trepidation will be relieved.

So, what are you going to learn from this book? Many topics will be covered, and safety is an important issue that will be discussed. Controlling dust in your shop is especially important to your safety—it’s a necessity and not a luxury! For those who have not selected a lathe, you can see what features are important to you and choose the correct lathe for your individual needs. You’ll also discover what other power tools are necessary for your shop and which ones are “nice to have.”

You’ll learn where and how to obtain wood—from the raw log or by purchasing a prepared blank—how to select turning tools, and how to use the ABC’s of tool control. Certain projects will be made with specific turning tools to enrich your tool control.

Once your project is turned, you will have to sand and finish it. Here we will discuss many different types of finishes. Once you have completed your work, how do you market the finished product? A gallery of finished work by a coalition of distinguished turners is available for admiration and for inspiration.

Finally, to me, the most important subject is troubleshooting and how to fix some of the problems you will encounter.

That’s it—a big task, but one I am sure you will enjoy. Now, with all that said, we have a lot of work ahead of us, so let’s have some fun and “make some dust!”

—Barry Gross

1 Getting Started

Before you start any actual turning, you’ll need to assess your tools and workshop space. For many beginners, this will mean buying tools, determining where your work space will be, and setting up your shop. As you think about what tools and space will be necessary, be certain to take safety requirements into consideration. It does not make any difference if you become the best turner the world has ever seen if you do not work safely!

• Safety

• Basic Workshop and Tools

• Choosing Wood

• Sharpening Tools

• Sanding

• Finishing

SAFETY

A top priority for everyone who wishes to work with a lathe and the accessories that accompany this rewarding pastime must be safety. Every book on turning has a section on safety, and there is a reason for this section. Despite continued warnings, people continue to work in unsafe ways!

One important but overlooked component to safety in a workshop is the ability to turn off a piece of equipment quickly in case of an emergency. Knowing where the off switch is located for each piece of equipment or having a master kill switch installed for the entire shop can be invaluable in case of a catastrophic event. Some other general guidelines to safety are listed in the following section. While many of these items may seem like common sense, accidents still do happen.

Photo 1.1. Goggles offer better protection than regular glasses.

EYE PROTECTION

The first and foremost safety issue concerns our eyes, and as such, eye protection is a must. It can happen in an instant: A small chip of wood flies off the lathe and scratches your cornea. Then, in the back of your mind, you can hear your mother’s voice telling you, “See, I told you you would poke your eye out with that thing.” The moral is wear eye protection!

The first line of defense, or the very least amount of protection to wear, is safety goggles. Goggles that wrap around your face offer better protection from flying chips than regular glasses (see Photo 1.1). The next step up is a full face shield. Finally, the best protection is a combination full face shield, which combines sound protection and a helmet with air filtration. Photo 1.2 shows a powered respirator. This type of respirator offers a continuous stream of filtered air flowing down inside the visor and supplying clean air for your lungs. In addition, there is built-in ear protection with the attached earmuffs.

Photo 1.2. You’ll get eye, sound, and dust protection with a powered respirator.

DUST CONTROL

Controlling fine wood dust from sanding is a pressing issue that must not be ignored. Repeated exposure to dust can cause problems for the eyes, sinuses, and lungs. Watering, redness, and conjunctivitis (pink eye) are some of the possible side effects when fine sanding dust gets in your eyes. Runny noses, sneezing, breathing difficulties, and asthma attacks are other side effects that can be triggered by fine particle dust.

It’s also important to note that a number of people are very allergic to certain types of dust from various exotic woods, such as cocobolo and kingwood. If you are allergic to certain types of woods, you may want to avoid them altogether. In addition, turning spalted woods can be hazardous because the fungal matter that is embedded in the wood is released when you either cut the wood with your tools or sand it with sandpaper. When this fungal dust is released into the air, it can cause serious respiratory problems.

To avoid some of these dust problems, at the very least, a washable dust mask (see Photo 1.3) should be worn. You could also choose a mask with replaceable filters (see Photo 1.4). To increase the protection level, a lightweight face shield with a built-in battery-powered air filter is a good way to combat dust and provide excellent eye protection (see Photo 1.5).

The next level in dust collection is to remove fine dust particles from the air as they are formed. A dust collection system, such as a shop vacuum or a larger one-horsepower, cartridge dust collector (see Photo 1.6 and 1.7), should be utilized. The larger dust collector in Photo 1.7 incorporates a .5 micron cartridge filter which is said to remove 99.8% of dust that is produced. In the event that the dust escapes either of these two collection systems, a ceiling-mounted dust collection unit can filter out airborne dust particles that the shop vacuum or the cartridge dust collector does not capture (see Photo 1.8).

Photo 1.3. Basic dust protection with a washable dust mask.

Photo 1.4. This mask features replaceable filters.

Photo 1.5. This respirator combines a face shield with a lightweight respirator built into the head piece.

Photo 1.6. A shop vacuum can be used for smaller dust control issues.

Photo 1.7. A one-horsepower dust collection system with a cartridge filter.

Photo 1.8. A ceiling-mounted dust collection system can catch airborne particles that a shop vacuum or a cartridge dust collector misses.

FATIGUE

Fatigue can be an important safety factor. If you are tired, do not attempt to start a project. If you feel tired after working in the shop for a while, stop working in the shop and get some rest; your project will still be there tomorrow. It only takes a momentary lapse of judgment for an accident to occur.

Photo 1.9. Avoid situations in which power cords can be a tripping hazard or can cause an overloaded circuit.

ELECTRICAL SAFETY

Since every shop is not like the New Yankee Workshop, and space is often at a premium, it is important to avoid having extension cords running all over your work area, causing either a tripping hazard or a potential overloaded circuit (see Photo 1.9). Try to keep cords out of the way or tape them down if they must run through high-traffic areas.

Photo 1.10. A full-length turning smock reduces the risk of loose clothing being entangled in the lathe.

HAIR AND CLOTHING

Loose clothing around the lathe should be avoided, and never lean over a lathe that is running. Wearing a turning smock helps to protect against flying chips, and some smocks will even keep fine dust particles out while allowing the garment to breathe (see Photo 1.10).

Place long hair under a hat or tie it back, as illustrated (see Photo 1.11). Never allow your hair to dangle near a running lathe (see Photo 1.12).

Photo 1.11. Long hair should be tied back or placed under a hat.

Photo 1.12. Never let long hair near a spinning lathe!

Checking the lathe

Before turning on the lathe, double check all of the following.

• Make sure the lathe is secured to the tabletop if it is a bench model or is securely bolted to the floor if it is a floor model.

• Turn the hand brake to guarantee that your work does not come in contact with the tool rest or any other part of the lathe (see Photo 1.13). Also, make sure that you adjust the tool rest to approximately the center of the workpiece, so the work will spin evenly when the lathe is turned on (see Photo 1.14).

• Ensure that the lathe speed is correctly set for the particular item you are turning. As a general rule of thumb, it’s always a good idea to start at the slowest setting and increase the speed as you feel more comfortable. If your piece is not even close to being round, or “out of round,” make sure that the speed is set for the slowest setting. High speeds can cause too much vibration, which is bad for the headstock and which will cause the lathe to “walk” across the floor or tabletop if it is not properly secured.

• Make sure your tools are sharp; dull tools make it much harder to obtain a smooth cut.

• Check your stance. You want to be comfortable when you are standing before your work. An improper stance can cause neck and back strain and lead to unnecessary fatigue. Your feet should be approximately shoulder-width apart as you stand parallel to the lathe. One hand should be resting on the tool rest, and the other hand should be holding the end of the tool near your hip. The idea is to move your body back and forth while keeping your hand close to your hip (see Photo 1.15).

• Make sure that the lathe is the proper height: The center of the work should be slightly above your elbow when you are standing in front of the lathe in a relaxed position.

Photo 1.13. Notice that the wood is hitting the tool rest. Do not allow this to happen! Your workpiece will be mangled and the spindle could be set loose in your workshop.

Photo 1.14. Tool rest height should be set so that the tool will be at the center of the workpiece, and the tool rest should be approximately ⅛" away from the spinning work.

Photo 1.15. Make sure that you are standing in front of the lathe with your legs comfortably positioned and the handle of the lathe tool close to your hip.

Photo 1.16. A finishing rag that “got away” from me and wrapped around the workpiece.

Photo 1.17. Properly discarded finishing rags should be laid out flat to dry thoroughly before they go into the trash. Do not discard them wet or balled up and thrown in with wood chips and other flammable material.

Photo 1.18. Wear protective boots and gloves whenever you are using a chainsaw to prepare wood for turning.

Photo 1.19. Never use a chainsaw in bare feet or with no protective gloves!

FINISHING SAFETY

When finishing a project, do not wrap any type of finishing cloth around your hand and then apply it to your work; it will inevitably get caught in your work and ruin your day (see Photo 1.16).

Spontaneous combustion is a very real situation that should be a concern for everyone. Follow the manufacturer’s suggestions on proper disposal of finishing rags and solvents to avoid any possibility of spontaneous combustion (see Photo 1.17).

HAND AND FOOT PROTECTION

A chainsaw, either gas or electric powered, is a great tool for reducing logs or other larger pieces of wood to sizes more suitable for turning. Whenever you are using a chainsaw, protective clothing should be worn (see Photo 1.18). See your particular chainsaw owner’s manual for the manufacturer’s safety guide. As ridiculous as it sounds, never use a chainsaw in bare feet or without gloves (see Photo 1.19)!

Turning gloves protect against wood chips striking your hands at a high rate of speed. These are not a necessity, but the first time you turn a piece of very dry hardwood and the chips sting your hands, you will wish you had a pair of gloves to protect them. Many gloves offer high-density pads on the grips to help eliminate the vibration caused by the turning tool and subsequently will reduce cramps and hand fatigue (see Photo 1.20).

Photo 1.20. Use turning gloves with padded grips to reduce vibration and to protect your hands from overheated, flying chips.