Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: CompanionHouse Books

- Kategorie: Lebensstil

- Sprache: Englisch

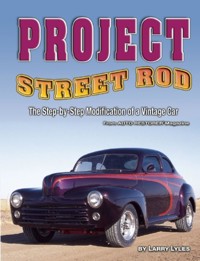

Project Street Rod is a complete guide to restoring a vintage car, written by auto-restoration guru Larry Lyles, a regular contributor to Auto Restorer magazine. In this detailed 21-chapter volume, Lyles walks the car owner through every step of the modification, from the disassembly of the car and to the finish touches, all with detailed instructions. Lyles transforms a beat-up 1946 Ford into a car the "looks nice, is very dependable, and is decked out with many of the [necessary] modern-day trappings." The title of each chapter is straightforward and tells the restorer exactly which step Lyles is explaining. The contents includes: beginning the disassembly, exterior and interior, and taking proper measurements of each component; installing the front suspension; installing the engine; shocks, spring and metal lines; floor pan installation, "suicide" doors, chopping the top, completing the top chop, seats, air-conditioning, and brake pedal; first project mock-up; working with body filler; color selection; new parts and fresh primer; ordering critical parts; the final clear coats; buildup; interior trim; headliner and center console; and finishing touches. Each step in every chapter is photographed as the author progresses along, with captions to spell out exactly what has to happen. The book offers helpful advice about choice of tools and tips to make even beginners feel confident about tackling the many steps involved. With nearly forty years experience in repairing, rebuilding, and restoring classic cars (and lots of unclassic ones like this 1946 Ford!), Lyles emphasizes the reader's need to organize his or her project by determining the course of the project, researching suppliers, making lists of parts and their conditions, creating spreadsheets of estimated and actual costs, and photographing each component as a reference for later in case the restoration goes off track. Each chapter ends with a "notes" page for the reader to record his or her progress, making this manual a practical workbook as well. When the reader gets to the final pages of the book and reads the sections "Starting Up" and "The Walk Around," there will be a true sense of accomplishment. An appendix of part suppliers and an index complete the book.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 333

Veröffentlichungsjahr: 2012

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

Barbara Kimmel, Editor in Chief

Nick Clemente, Special Consultant

Ted Kade, Consulting Editor

Kara Smith, Production Supervisor

Bill Jonas, Layout Artist

Indexed by Melody Englund

Copyright © 2009

Photos copyright © 2009 by Larry Lyles

All rights reserved. No part of this book may be reproduced, stored in a retrieval system, or transmitted in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of BowTie Press®, except for the inclusion of brief quotations in an acknowledged review.

Library of Congress Cataloging-in-Publication Data

Lyles, Larry.

Project street rod : the step-by-step restoration of a popular vintage car / by

Larry Lyles.

p. cm.

“From Auto restorer magazine.”

ISBN 978-1-933958-39-2

eISBN 978-1-620080-13-9

1. Hot rods—United States—Design and construction. 2. Ford automobile—Customizing. 3. Ford automobile—Conservation and restoration. I. Title.

TL236.3.L95 2008

629.2’3–dc22

2008014255

Contents

ACKNOWLEDGMENTS

INTRODUCTION

CHAPTER 1

GETTING STARTED

CHAPTER 2

DISASSEMBLY AND MEASUREMENTS

CHAPTER 3

INSTALLING THE FRONT SUSPENSION

CHAPTER 4

INSTALLING THE ENGINE

CHAPTER 5

SHOCKS, SPRINGS, AND METAL LINES

CHAPTER 6

FLOOR PAN INSTALLATION

CHAPTER 7

INSTALLING “SUICIDE” DOORS

CHAPTER 8

CHOPPING THE TOP

CHAPTER 9

COMPLETING THE TOP CHOP

CHAPTER 10

TIME FOR SEATS, AC, AND A BRAKE PEDAL

CHAPTER 11

THE FIRST PROJECT MOCK-UP

CHAPTER 12

WORKING WITH BODY FILLER

CHAPTER 13

TIME TO SELECT COLORS

CHAPTER 14

NEW PARTS AND FRESH PRIMER

CHAPTER 15

ORDERING CRITICAL PARTS

CHAPTER 16

THE FINAL CLEAR COATS

CHAPTER 17

THE BUILDUP BEGINS

CHAPTER 18

THE BUILDUP CONTINUES

CHAPTER 19

INTERIOR TRIM

CHAPTER 20

HEADLINER AND CENTER CONSOLE

CHAPTER 21

THE FINISHING TOUCHES

APPENDIX

Acknowledgments

I would like to thank the people who put a lot of time and effort into the rebirth of this car. Without their help, this project might never have been completed: Ted Kade, editor, Auto Restorer Magazine, whose expertise with words breathed life into the articles this book was taken from; John Sloane and Joe Richardson, the Eastwood Company, two guys who delivered on every promise made and then some; my wife, Pat; my son, Bryan; and the Biscuit, whose help, assistance, and enthusiasm keep me going.

Introduction

Had someone asked me as I began to put the finishing touches on the Project Mustang car if I planned to start another big project, I would have said “no way.” I desperately needed a couple of days off to take care of a few nagging issues that were weighing heavily upon me, the weather was exceedingly hot, and starting a new project just wasn’t what I had in mind.

My, how things can change so quickly. The rains came, the air cooled down, my battered body began to heal, and my apprentice, Bryan, found a 1946 Ford Business Coupe. But don’t start laughing just yet. As you already know, my forte is 1960s muscle cars. I restore them, revamp them, retro them, and revive them. I don’t do ’46 Fords.

But then Bryan convinced me to take a walk around the ’46 and give some thought to what could be done to the car. I liked the shape, if modified a little. I liked the interior room, if modified a little. I also liked the fact that someone else had already transplanted a Chevy 350 under the hood, although it, too, could stand to be modified a little. I was beginning to like what I saw.

I made a second trip around the car to kick the tires, then made up my mind that this 1946 Ford was going to get a new life, and I was going to eat my own words about not doing ’46 Fords.

The catch was I had no desire to take this car apart and rebuild it back to original, the way I did in Project Charger and Project Mustang. What I had in mind would require a completely different mind-set on my part.

My thought was to take this aging vintage ride, which even in its prime was not much more than a means for moving from point A to point B, and upscale it into something very nice. Don’t get the idea I’m about to hack apart a perfectly good original vintage ride and change it into something different. This car sat in the weeds far too many years to even consider that option. What the mice didn’t eat the sun baked into crumbs. All I have now is a bullet-riddled hull in need of a lot of TLC and a whole host of modifications designed to transform this car into one heck of a nice ride.

I’m not looking for maximum horsepower, radical looks, or big tires. My goal is to transform this ’46 Ford into something that looks nice, is very dependable, and is decked out with many of the modern-day trappings my wife would insist are necessities, not accessories.

What does that mean? In this case it means taking the car down to the bare frame and starting over using the latest in automotive ride, handling, and performance technology to rebuild it. In the end, what you will see from the outside is a somewhat modified ’46 Ford; but on the inside, it will have all the modern accoutrements necessary to bring this car up to today’s driving and handling standards.

In some parts of the country, this type of work, in which a car that in many cases is unsafe to drive at 50 mph is taken and modified to be safe to drive at any speed desired, is referred to as “resto-mod.” In the sticks where I come from, we simply call it making the car “wife approved.”

CHAPTER 1

GETTING STARTED

Take a look in photo 1 at where this car came from. The previous owner informed me he had spent several hours cutting down heavy brush and small trees just to reach the car. Once access to the car was gained, he towed the car into the open where it could be photographed, loaded onto a trailer, and transported to his garage. That was a few years ago, and I assure you that in the meantime the overall condition of the car wasn’t drastically improved upon.

A NICE CAR IT ISN’T

The ’46 was a bomb, to say the least. A lot of vital parts were missing, and the ones that were there had been used for target practice. I’m not stepping out on a limb when I say this car probably would have never seen pavement again; and if by some fluke it had, it would have been a risk to everyone within 100 yards of it. But that’s no longer true. I’ll be taking this aging hull of a car apart and making a lot of modifications designed to bring this car back to something that will handle and drive like a dream.

How am I going to do that? Let’s move this bomb of a ’46 into the shop and start by defusing it.

The previous owner was kind enough to remove all of the front sheet metal, which for the time being has been piled in a corner of the shop. That has left everything forward of the firewall exposed enough to give me a better look at what I have (photo 2).

REPLACING THE SUSPENSION

What I see I really don’t like. The front I-beam axle setup may have been a good suspension system in its day, but it can’t hold a candle to the modern IFS (independent front suspension) units available today (photo 3). Nor am I thrilled with the drum brake system or the manual steering setup. What this car needs is a good SLA (short arm, long arm) suspension system coupled with a set of disc brakes and rack and pinion steering.

The good news is that I can purchase an off-the-shelf IFS unit that will come already equipped with disc brakes and rack and pinion steering. That will let me rip out the old front I-beam axle setup, then weld in the new IFS unit, and end up with a state-of-the-art front suspension. The bad news is that most off-the-shelf IFS units won’t simply drop into place under the ’46. To get one to fit, I’ll need to make some modifications to the frame. As I move deeper into this project, I’ll go through the entire process of modifying the frame to accept such a unit.

PHOTO 1: Parked in the weeds for many years, it took the previous owner two days to extract the car and save it from the “rust worms.”

PHOTO 2: With the ’46 finally in the shop, it is time to take a hard look at what I have.

THE ENGINE AND TRANSMISSION NEED ATTENTION

Looking at the engine the previous owner had already installed in the car, I know I have a very solid Chevy 350 bolted to a pretty common 350 automatic transmission (photo 4). Depending on the budget, I hope to be making some internal changes to the engine to boost its output as well as making a few cosmetic changes designed to dress up this engine. I’ll also be thinking about giving the carburetor the toss, in favor of something a little more high tech and user friendly to the driver, such as a multi-port fuel injection system from Affordable Fuel Injection. I’ve yet to teach Bryan the subtle nuances of starting a cold engine with a 650 Edelbrock mounted on it. I don’t think the term pump it computes to a younger generation brought up on fuel-injected grocery haulers.

Anyway, as far as the transmission goes, overdrive would be nice, but sometimes you just have to “run what you brung.” That doesn’t mean this transmission is a slouch; GM thought enough of it to plant it under a few million Chevrolets. As long as I send it out for a once-over at the transmission shop, it should serve this project quite well for a number of years.

PHOTO 3: I-beam front suspension with its drum brake setup has got to go. I’ll replace everything here with something much better.

PHOTO 4: The Chevy 350 is a good start toward making this car really purr. It needs a little dressing up, but that’s for later.

Crawling under the car to check the clearance between the transmission and the X-member, I can see that the frame will require some extensive modifications in this area also. The transmission is bumping the X-member on the right side and has less than a 1/4-inch clearance on the left side. In an ideal world, I’d like to see at least a 1/2-inch clearance all around the transmission. That means I’ll be modifying the X-member to gain that desired clearance.

TOP AND BOTTOM METAL WORK

Working my way farther back, I’m finding a lot of rust in the passenger compartment floor pan area that will have to be dealt with, plus a massively bubbled roof that is just begging for some attention. The floor pans are an easy enough fix. I’ll simply cut them out and replace them with new pans fabricated here in the shop. The bubbled roof is going to present more of a challenge (photo 5). It will have to be chopped.

But then, that is an art in itself. If you have ever wandered through the local car shows admiring all of the painted iron on display, I’m sure you have noticed at least one ride with the windshield so narrow you can’t help but wonder how the driver can see where he is going. That’s a huge problem I want to avoid when it comes time to chop this top. I’m not fond of massive tops, but I am fond of seeing where I’m going.

The flip side to the overly chopped top is the chop that leaves the casual observer wondering if the top has been chopped at all. I don’t want to spend the amount of time and money required to do a first-class top chop and then in the end realize I had needed to remove another inch of metal to really make this ride look right. To get it right, I’ll use an old school trick combined with new-school technology to determine the correct amount of chop the roof panel should have.

TIP

A good way to keep your pants clean when going under a vehicle is to purchase a mechanic’s creeper. This board on wheels keeps you off of the cold floor and makes negotiating the tight clearance between car and floor much easier.

I’ll dispense with going into the details of how this chop will be accomplished until later. Instead, I’ll, explain the odd-looking car in photo 6. The lines across the door opening were created using masking tape. The strips of tape are spaced 3/4 of an inch apart. That will allow me to take a photo of the car, blow it up to a larger size, then cut and crop it along the different tape lines until I determine how much chop is enough to make this car look the way I want it to look, I’ll tack my cut and cropped shot of the car to the shop wall to serve as a reference guide as I work. I know, Photoshop can do that on the computer, but it can’t blow up the picture enough for an old goat like me to get a real good look at it. I’m old school in that regard and proud of it.

Moving on toward the back of the car, the trunk floor pan is almost as rusty as the passenger compartment floor pan. Replacing it won’t pose a serious problem until I toss into the mix the need to replace the fuel tank. I’m not thrilled with the fender-mounted fuel filler neck, so I will be making changes in that area also.

Under the rear floor pan is a GM-type rear axle assembly that had been removed from something with a rear coil spring suspension and modified to accept leaf springs. Nothing about this setup is acceptable to me, so the only alternative is to remove everything under here and start over. I just happen to have a Ford 8.8 rear axle complete with disc brakes and a factory four bar-type suspension that should be an easy fit.

IMPROVING INTERIOR COMFORT

Moving back to the passenger compartment, I know from having helped hot-rod a few cars over my career that there are two basic areas of concern located between the firewall and trunk compartment. The first is the dash area. Leg room can become a premium when trying to tuck air conditioning, stereo equipment, and a variety of gauges into an already confined space. This will take some careful thought and consideration as to how to proceed.

The other concern is the back seat. Did I say back seat? Yes, I did. The ’46 may have begun life as a business coupe, void of a back seat, but it has more than enough room to accommodate a rear seat. It won’t have the space of a limo, but it should have ample room to stuff a grand-kid or two into the car to make the day’s outing a little more family friendly.

PHOTO 5: From this angle, you can almost get a feel for how the roof will look once it has been chopped. From any other angle, the roof is one huge bubble.

PHOTO 6: The first step in the old-school process of chopping a top is to lay reference lines on the car to be used later to determine the exact amount of chop this car will receive.

TIME FOR A WISH LIST

Normally, I would bring out the camera and note pad and start a master list as I begin to take this car apart. However, there isn’t a lot to be taken apart on this car, and most of what I will be taking apart will not be put back on the car anyway. I think the best course of action is to start by compiling a wish list of desired changes, then venture onto the Internet in search of parts and parts catalogs. That will help me construct a budget for this project as well as help establish a sequence of steps for rebuilding this car.

CHAPTER 2

DISASSEMBLY AND MEASUREMENTS

Whenever I begin a new project, the first thing I do is position the car in the shop and elevate it on jack stands. That places the vehicle at a comfortable working height and also affords me ample room when I need to go underneath the vehicle to remove all those road-grime-coated parts. This project will be approached a little differently.

For the time being, the wheels will stay on the car and the car will stay on the floor. That’s because I have a number of modifications I want to make to the frame under this car, and the best way to access the frame to accomplish those modifications is to remove the body. To do that, I’ll use an engine hoist to lift the body straight up, then I’ll roll the chassis out from underneath. The body will be sent out for media blasting to get rid of the rust while I concentrate on modifying the frame. How do I maneuver a bulky car body around the shop? I have a steel cart measuring roughly 4 x 6 feet with rollers under it (photo 1). It is strong enough to support almost anything I place on it.

SOME CHASSIS ANALYSIS

With the body off of the car, three things jump out at me as I study the chassis. First, the front suspension is an I-beam-style axle, and it has got to go. I-beam axles may look good under a Bucket T or a ’32 Ford, but this type of suspension is never going to give me the quality of ride or degree of handling I’m looking for with this project (photo 2).

Second, the transplanted GM rear axle assembly and its accompanying leaf spring suspension also must go (photo 3). I have no kick against GM products or leaf spring rear suspensions, it is just that I have a very nice Ford 8.8 rear end complete with a factory four-bar suspension that not only will give this car a smooth ride but also will give me some options when it comes to determining the final riding height of the car.

Third, now that I have the body off of the frame and a better view of the center X-member, I can see some hacking and chopping has already taken place to get the automatic transmission to fit. I use the word fit loosely, as this installation is anything but acceptable (photo 4). The transmission is bumping the frame on the right side and doesn’t offer much more room on the left. I knew these were areas of concern coming into the project, so all that is left for me to do now is go to work and fix them.

PHOTO 1: The body is placed on a steel cart to allow me to move it around the shop as needed.

PHOTO 2: This I-beam axle and drum brake setup may have been state of the art in 1946, but to meet today’s standards it has to go.

PHOTO 3: The GM rear axle came from a car with a coil spring suspension. It was converted to leaf springs, and now I’m converting it to dust gatherer.

THE DISASSEMBLY BEGINS

I start by placing the chassis on jack stands so I can remove the wheels and gain a little more working room. Next, I remove the engine and transmission. I’d like to hang the engine on an engine stand and send the transmission out for a rebuild, but I’ll need both units a little later to help reconfigure the engine and transmission mounts. So for now, I leave the transmission attached to the engine and store them in the corner where hopefully they will be out of the way until I need them.

The next piece to go is the GM rear end. A few bolts and the unit will drop right out. I’m not going to concern myself with marking the rear axle centerline on the frame to help position the new axle because the previous owner installed this rear axle, and I can’t be sure he installed it to the correct dimensions in the first place. To determine the correct rear axle centerline, I have access to a set of original 1946 Ford frame dimensions that will at least give me a place to start.

The front I-beam axle is a different story. Up here, the old suspension is basically stock, so before any of these parts are removed, I’ll mark a reference point on the frame to help define where the front axle centerline should be located. I’ll also take a measurement from the axle to a point roughly 4 feet back on the frame that will help me when I’m ready to install the new front suspension.

PHOTO 4: The lack of clearance around the transmission makes this installation unacceptable. I’ll have to make some modifications to this part of the frame.

The reference point for the axle centerline is found by laying a straightedge across the frame from center to center of both axle kingpins and marking the centerline on the top of the frame. I won’t use this mark as the ultimate guide to positioning the new front suspension within the frame, but it will serve as a base reference point later when I install the new front suspension cross member.

The other measurement I need is from the axle centerline mark on the frame back to a hole in the top of the frame located just behind the front body mounts. That measurement is 52 inches. With these two specifications noted and marked, I can unbolt the old front suspension and remove it as a complete unit.

DOWN TO THE BARE BONES

With the ’46 stripped down to the bare frame, my next step is to determine an approximate final curb height for the car. How am I going to manage that with no suspension under the car? Actually, it won’t be that difficult. Since I’ll be modifying the frame to accept new suspension components, I can control the position of those components by the way I install them on the frame. That begins by determining the amount of ground clearance I’ll ultimately want under the car. I’ll use the body mount perches riveted to the sides of the frame as measuring points and level the frame at 14 inches (photo 5). This is an arbitrary number and may change as I move deeper into the project, but for now it gives me a good place to start.

The plan also calls for giving this car a few degrees of front-end rake when finished. That means the front of the car will sit slightly lower than the rear, so leveling the car at 14 inches will actually end up giving me a car that sits roughly 16-18 inches from floor level at the rear and roughly 10-12 inches from floor level at the front when completed. Sound confusing? It does. But trust me, everything will work out. I just need the frame to sit dead level for now to ensure that every modification I make to the frame ends up level to the frame and not installed crooked or leaning off toward the back forty. What did I use to level the frame? In this case, a long carpenter’s level isn’t of much use since the frame has several dips and bumps along its length. Instead, I opted for a short, 12-inch-long level I could place at various points along the frame, both lengthwise and crosswise, to get it level. Having a large supply of paint stir sticks also helps, as they can act as shims where needed between the jack stands and frame.

Now I can move my replacement Ford 8.8 rear axle into position under the car. I use three jack stands to support the unit, placing a stand just inboard of each brake flange and another under the pinion yoke to support the front of the axle.

I set the rear axle centerline height at 14 1/2 inches just because my jack stands have a lock at that exact point. If the jack stands had locked at 14 or 15 inches, either would have worked just as well (photo 6).

To be sure the axle is positioned squarely within the fame as well as positioned correctly lengthwise, I referred to the set of 1946 Ford frame dimensions mentioned earlier and place the 8.8 axle at 32 1/4 inches forward of the rear-most tip of the frame when measuring from the axle centerline to the end of the frame.

To determine the square placement of the axle assembly within the frame, I take cross measurements between the axle and the frame from side to side. When those measurements are equal, I know the axle is positioned squarely within the frame (photo 7).

With the axle assembly positioned correctly, I need to do two more things. First, I want to level the pinion yoke and take a measurement from the center of the yoke to the floor, in this case 12 1/2 inches. I file this measurement away until the engine and transmission are ready to be installed.

After that, I need to elevate the pinion and set it at 3 degrees positive. This is an absolutely critical step, as 3 degrees positive is the pinion angle determined by car manufacturers and hot rod builders many years ago to be the optimum angle for installing and mounting any rear axle assembly. How come? Consider how difficult it is to keep a double-hinged tube balanced and rotating in a perfectly straight line when spun. Add an upward bias to the hinges to eliminate the straight line effect, and suddenly the tube becomes very easy to balance and spin. In this case, that tube is the driveshaft.

PHOTO 5: A yardstick is used to help set the riding height of the car by measuring the distance from the floor to the body mount, in this case, 14 inches.

PHOTO 6: Sticking with my proposed riding height of 14 inches, the rear axle centerline is set to 14 1/2 inches. The extra 1/2 inch is to compensate for the jack stands and will not affect the actual riding height when the car is completed.

PHOTO 7: Taking cross measurements is a vital part of centering the rear axle within the frame.

To find the 3 degrees positive angle, I place a magnetic protractor on top of the pinion yoke and shim the yoke up by adding paint stir sticks between the yoke and the jack stand until the magnetic protractor reads 3 degrees positive (photo 8). I’ll get deeper into the need for the level pinion measurement as well as the role this 3-degree placement plays in this build once I’m ready to install the engine and transmission. For now, I need to concentrate on mounting this axle to the frame.

SELECTING A SUSPENSION SYSTEM

When it comes to mounting and supporting a rear axle assembly, the average car builder has a variety of suspension systems from which to choose. They range from the common everyday suspensions found under factory-built cars to the more exotic systems designed and produced through the racing and street rod building industries.

The most common rear suspensions found are the same types of rear suspensions the auto makers have been using for years: the leaf spring and coil spring suspensions. The basic difference between these two suspensions has to do with the axle. The leaf spring suspension not only supports the rear axle as it dampens the effects of the road, it also provides the means by which the axle is mounted to the vehicle. The coil spring suspension also supports the vehicle and provides a dampening effect for the bumps on the road, but the axle itself is secured to the vehicle by a set of four bars, or four mounting arms, that hold the axle in place while allowing it to move up and down within the frame.

PHOTO 8: The pinion angle is set to 3 degrees positive in order to give the axle housing a slight upward bias.

As previously mentioned, the rear suspension I removed from this car used leaf springs to support the axle assembly and in any other situation would have been an adequate suspension. However, replacing the unit with the Ford 8.8 rear axle instantly transforms this project car into a vehicle equipped with four wheel disc brakes. Not a bad trade-off.

If there is a downside here it is that the Ford unit was designed as a coil spring, four mounting arm-type suspension. That means more work installing the unit, but it also means I can make some changes and toss the coil springs in favor of adjustable coil-over shocks.

Adjustable coil-over shocks offer two things I might not otherwise have. First, adjustable coil-over shocks will allow me to adjust the final riding height of the car by varying the amount of compression applied to the coil springs. Second, if I don’t like the ride the coil-over shocks are giving me, I can easily swap out the coils to give the car a stiffer ride or, if desired, a softer ride.

But there is nothing to bolt this rear axle to. That’s why every decent-size city has a metal mart. I’ll make a visit to my local mart and purchase a 10 foot length of 2 x 2-inch square steel tubing (this is industry jargon) and an even dozen 1/8-inch-thick steel plates measuring 4 x 6 inches. I’ll use the tubing to construct the necessary mounting brackets and the steel plates to construct mounting boxes to accept the four axle mounting arms.

Photo 9 shows one of the lower mounting brackets fabricated from the 2 x 2-inch square tubing. The triangular shape gives the bracket plenty of strength and provides adequate area to weld the unit to the frame.

To mount these brackets, one on the right and one on the left, I cut square openings inside the frame rails to allow the brackets to slide into the rails, where they can be welded into place (photo 10). Notice the clamps. For the time being, nothing has been welded. I save the welding until I have everything fitting the way I want them to fit.

TIP

New steel is often coated with a rust preventative. Remove this coating using a degreasing agent before welding any new pieces to your frame. Paint will not stick to the coating, and it is much easier to remove such a coating now.

PHOTO 9: One of the lower mounting brackets fabricated from the 2 x 2-inch square tubing.

To attach the upper axle mounting arms to the frame, I cut square holes in both sides of the frame and slide a length of 2 x 2 square tubing through the frame and extend it out 1/4 inch on both sides. This allows me to weld the tubing to the frame on the outside of the rail as opposed to cutting access holes inside the frame rail to facilitate welding.

Next, I use the 4 x 6 steel plates to form gussets to attach the mounting arms to the square tubing. Once the mounts are secured, I finish this installation by capping the ends of the square tubing with scraps from the 1/8-inch steel plate.

To double-check my work, I again measure the positioning of the axle within the frame to be sure everything remained square and in good alignment. I also use a floor jack to move the axle up and down to be sure nothing is binding and that I have smooth operation everywhere. When I’m sure everything is in place, I finish welding all of the brackets and grind each weld smooth.

MOUNTING THE SHOCKS

With the axle solidly in place, my next step is to mount the coil-over shocks. The actual up-and-down travel of these shocks is 5 inches. That means with the frame and the rear axle sitting at the assumed riding height of the car, I need to mount the shocks so that they will have 2 1/2 inches of travel up and 2 1/2 inches of travel down.

The upward travel, or extension travel, of the shock isn’t so critical because this movement places virtually no stress on the shock; it merely extends its full length and stops. At that point, the rear wheel lifts and in an extreme case may even lift off of the ground.

PHOTO 10: Before welding, the entire rear axle mounting system is mocked up and clamped into place.

The downward travel, or compression travel, of the shock is more critical because this movement places a lot of stress on the shock as it attempts to compress the oil or gas inside the shock. This compression action, if pushed to an extreme, can result in the shock rupturing and rendering it useless. To prevent the shock from overcompressing, I need to install rubber cushions between the axle unit and the frame. These snubbers, as they are called, stop the upward travel of the axle, thereby preventing the shock from being overcompressed.

I elected to use rubber lower control arm stops found on the 1968 Mustang and mounted each one to a bracket made of 2 x 2 square tubing extended downward from the frame (photo 11). When the axle is forced upward, it will bump into the snubber and stop, thereby saving my shock.

The snubber brackets are 6 inches long, with each snubber extending that length by 1 inch. That gives me an upward axle travel from the neutral position of 2 1/4 inches, but that is still enough to provide this car with a smooth, secure ride.

PHOTO 11: This bracket holds the rubber axle stop designed to prevent the coil-over shock from bottoming out and being damaged.

CHAPTER 3

INSTALLING THE FRONT SUSPENSION

There is good news when it comes to removing an old front suspension and replacing it with a more modern suspension. The aftermarket street rod industry has had many years to design and produce replacement units that far exceed the performance of the older original suspensions.

The bad news is that if the installation of the new suspension isn’t done correctly, the vehicle being modified may actually drive and handle worse than it did with the vintage front suspension. The lesson here is, if you are considering such an undertaking, buying new parts doesn’t guarantee a job well done. For that you will need to gather all the information you can find concerning how a suspension works before ever turning a bolt on the old suspension to remove it. Where do you find such information? This book is a good place to start. After that, visit the local front end alignment store, where you can talk to the tech about what you are doing. His time costs money. Pay him.

THE PROJECT’S NEW SUSPENSION

The front suspension I’ve chosen for this project is known as an IFS, or independent front suspension. It is also known as the Mustang II front suspension because it is basically an improved version of the original Mustang II front suspension. In the restoration world, this front end is also known as an SLA suspension, or short arm, long arm suspension. Short arm means the upper control arm is shorter than the lower control arm, as shown in photo 1. OK, I know this is going to come up, so here goes. The upper control arm is shorter because this setup acts to keep more of the tire on the road at all times, especially when cornering, and that greatly improves upon the handling qualities of the vehicle.

This type of replacement front suspension consists of three main components: a front cross member, shown already welded into place on the frame in photo 2, and the right and left upper control arm mounting brackets, at this point only tack welded to the frame.

Photo 2 shows how the front cross member is positioned within the frame and how the upper control arm brackets are positioned on top of the frame rail, and it also points out a lot of other things that are going on at the same time.

PHOTO 1: A bird’s-eye view of an SLA front end. Notice how much shorter the upper control arm is than the lower control arm.

PHOTO 2: This is a finished view of the new cross member installation. Notice the new round tube at the front of the frame put there for cosmetic reasons, the dogleg created just aft of the cross member when the frame was narrowed, the new cross member itself, the upper control arm mounting plates, and, finally, the motor mount brackets. Phew! No wonder this took forever!

For instance, the frame has been narrowed to fit the new front cross member, the engine mounts have been tack welded into place, and the front tip of the frame has been cosmetically dressed out with a round steel tube. These are all steps that must be considered before ever opening the toolbox to start building a new front suspension.

These parts may be the guts of the new suspension, but in the overall scheme of things they represent only three pieces in a long list of parts that are needed to complete the transformation. Let’s take a look at the rest of the components that make up this IFS unit, and then I’ll explain some of the basics that make the IFS unit such a good choice when you are updating an older vehicle with a modern front suspension.

THOSE CUSTOM CONTROL ARMS

If you have ever had a disassembled front suspension, all of the parts in photo 3 will look familiar. With the exception of the control arms, which are custom-made tubular units, all of these pieces can be purchased off the shelf at the local automotive parts store. These are all Ford or Ford-compatible components and are as follows: disc brake rotors, disc brake calipers, spindles, coil springs, shock absorbers, and a power rack and pinion steering unit.

Did I say power steering? Yes I did. Recall that I said at the beginning of this project the goal would be to bring this car up to today’s standards and make it wife approved. Power steering is one of those requirements.

TIP

When adding the power steering option to an aftermarket IFS unit, be sure to ask the supplier about the source of the power rack and pinion unit. New power steering lines will be required, and you will need to know if the rack and pinion is from a Mustang, Pinto, or Thunderbird and the year model.