Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: IMM Lifestyle Books

- Kategorie: Lebensstil

- Sprache: Englisch

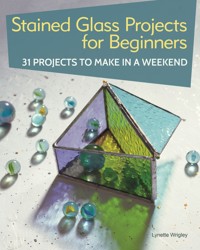

Stunning to look at and exciting to make, stained glass work is perennially popular. Discover the rich and versatile craft of stained glass with this complete beginner's guide. Bestselling author and professional stained glass artist Lynette Wrigley shows you everything you need to know to make beautiful decorative pieces for the home. Thirty-one step-by-step projects range from copper foiled and leaded window panels to candle holders, mirror and picture frames, lightcatchers, and more. Expert methods for cutting and polishing, tracing patterns and soldering are explained with the novice in mind. Even if you've never cut a piece of glass before, Stained Glass Projects for Beginners will inspire you with the fascinating potential of stained glass.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 151

Veröffentlichungsjahr: 2019

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

Published 2019—IMM Lifestyle Books

www.IMMLifestyleBooks.com

IMM Lifestyle Books are distributed in the UK by Grantham Book Service, Trent Road, Grantham, Lincolnshire, NG31 7XQ.

In North America, IMM Lifestyle Books are distributed by Fox Chapel Publishing, 903 Square Street, Mount Joy, PA 17552, www.FoxChapelPublishing.com.

© 2019 by Lynette Wrigley and IMM Lifestyle Books

Produced under license.

The patterns contained herein are copyrighted by the author. Readers may make copies of these patterns for personal use. The patterns themselves, however, are not to be duplicated for resale or distribution under any circumstances. Any such copying is a violation of copyright law.

Stained Glass Projects for Beginners is a collection of new and previously published material. Portions of this book have been reproduced from the following books: Step-by-Step Crafts Stained Glass (978-1-85974-230-0) and Stained Glass in a Weekend (978-1-85974-090-1).

Technical reviewer: Matt Kolenda, www.kolendaartglass.com

Print ISBN 978-1-5048-0104-1eISBN 978-1-6076-5562-6

For a printable PDF of the patterns used in this book, please contact Fox Chapel Publishing at [email protected], stating the ISBN and title of the book in the subject line.

Library of Congress Cataloging-in-Publication Data

Names: Wrigley, Lynette, author.

Title: Stained glass projects for beginners / Lynette Wrigley.

Description: Mount Joy : IMM Lifestyle Books, 2019. | “Contains step-by-step projects designed for those that are complete beginners to stained glass making. Includes information on the essential tools and techniques, as well as many visual examples”--Provided by the publisher. | Includes index.

Identifiers: LCCN 2018043585 (print) | LCCN 2018044773 (ebook) | ISBN 9781607655626 (ebook) | ISBN 9781607655626

Subjects: LCSH: Glass craft. | Glass painting and staining. Classification: LCC TT298 (ebook) | LCC TT298 .W754 2019 (print) | DDC 748.5028/5--dc23

LC record available at https://lccn.loc.gov/2018043585

We are always looking for talented authors. To submit an idea, please send a brief inquiry to [email protected].

Opening Your Window to Stained Glass

Anyone who has encountered the beautiful stained glass windows displayed in cathedrals and churches will have marveled at the glorious colors of the glass and the skill of the craftsmen. Today, more and more people are discovering for themselves the rich and versatile craft of stained glass as an expression of creativity. Whether you’re seeking a hobby or you’re a seasoned artist turning to a new medium, you’ll find working with stained glass to be challenging and rewarding.

Stained glass is now a regular fixture on the craft scene. It is a medium used not only for creating windows, but also for all manner of decorative objects, from lightcatchers to mirrors to jewelry to sculptures. The glass itself is available in the most wonderful, diverse array of colors and textures. Although colors and types of glass are suggested for each project in this book, the choice is ultimately your own, so you can let your imagination go wild.

The aim of this book is to provide total beginners with the technique essentials and with helpful ideas for making gorgeous items for the home. It includes a variety of step-by-step projects that will allow you to achieve striking results. Selected to show a variety of decorative glass work, the projects range from small three-dimensional items to large, colorful mirror frames and windows. Read the Getting Started section before beginning the projects in order to familiarize yourself with the tools you will need and the methods you will encounter, including cutting glass, soldering, copper foiling, leading, and more. These basic techniques can be mastered with practice and a little patience.

If you have never cut a piece of glass before, do not be daunted. Whenever I teach weekend workshops on stained glass, I am constantly inspired by people’s ability and creativity. Once they realize the craft is not so difficult, their enthusiasm is boundless. There is a magic to stained glass that becomes irresistible once you begin working with it. I hope that this book inspires you, teaches you, and shows you the fascinating potential of stained glass.

Contents

GETTING STARTED

Glass

Glass Accessories

Tools and Equipment

Cutting Glass

Assembling by Copper Foiling

Assembling by Leading

Designing Your Own Pieces

PROJECTS

Sunflower Appliqué

Candle Cube

Blue Gallery

Candle Stand

Green Square Mirror

Decorative Glass Panel

Pressed Leaf Mirror

Etched Tumblers

Etched Coasters

Etched Gallery

Blue & Silver Picture Frame

Mirror Sconce

Triangular Box

Pressed Flower Mobile

Wild Creations Gallery

Mirror Brooch

Glass Pendant

Primary Colors Gallery

Lightcatcher

Petal Picture Frame

Triple Candle Holder

Leaded Light

Clocks, Mirrors, and Frames Gallery

Leaded Window Panel

Etched Mirror

Heart Mirror

Autumn Leaves

Tropical Fish Panel

Hanging Roundel

Picture Frame

Appliqué Poppy Panel

Yellow and Green Gallery

Three-Dimensional Star

Candle Lamp

Butterfly Roundel

Aegean Candle Box

Tiffany Window

Window Gallery

Patterns

Suppliers

Photo Credits

About the Author

Acknowledgments

Getting Started

There are surprisingly few special tools required to start working with stained glass as a beginner. However, these few tools are essential and worth investing in, because they will make the whole process of learning the craft easier and more enjoyable. Familiarize yourself with the tools and equipment and how to use them. Read through the safety checklist very thoroughly. When working with glass, use common sense and handle it carefully. Small nicks and cuts are inevitable from time to time, but you will rarely experience anything worse. Keep a first aid kit handy just in case.

Read this chapter carefully before you begin and refer back to it when making the projects for more detailed instructions on techniques such as cutting glass or applying copper foil. It is also a good idea to practice some of these techniques on scrap glass in order to build up your skill and confidence. Once you have mastered these techniques, you will be able to adapt projects to your needs and make your own unique pieces.

Glass

A stained glass supplier is the best source of materials and information about the many types of colored art glass that are produced. Many suppliers also offer a mail order service. However, until you are familiar with the wide range of colored glass that is available, try to visit a store first to see the varieties on sale. Glass can be divided into two main categories: antique glass and rolled glass, better known as cathedral glass.

Antique Glass

The name of this glass does not refer to the age of the glass, but to the centuries-old technique by which it is made. Antique glass is blown by mouth as opposed to being machine-made. Glass is blown into a long cylinder. The ends are removed and a cut is made in the side. It is then re-heated and folded out into a flat sheet. Each sheet of antique glass is unique, having its own particular qualities, irregularities, and range of colors.

Rolled or Cathedral Glass

This name refers to glass that is made by machine rather than by hand. When the glass is in a hot, liquid state, it is rolled out onto a metal surface. There are many types of machine-made glass made by different companies, and each may have different cutting properties and characteristics. Here are just a few of the many types you will come across.

OPALESCENT GLASS

Most, but not all, opalescent glass is machine-made. It is characterized by its opacity, in contrast to the other types of machine-made glass, which are generally transparent. It is seldom one color; rather, it may be a mixture of whirling colors or streaks spreading throughout the sheet. It comes in various degrees of opacity.

Streaky

Roundel

STREAKY GLASS

For this type of glass, two or more distinct colors are swirled together in one piece of glass.

WATERGLASS

Waterglass is a trade name rather than a general category of glass, and it is made by the Spectrum Glass Company. This glass has an even, wavy, rippled appearance on the surface and is available in a beautiful range of vibrant colors.

SEMI-ANTIQUE GLASS

This glass has a distinct surface pattern of tiny striations that are intended to simulate the appearance of mouth-blown glass. It is available in many colors and is easy to cut, making it ideal for beginners.

IRIDESCENT GLASS

This type of glass has an iridescent shine on its surface, similar to oil on water.

FRACTURES AND STREAMERS GLASS

This kind of glass can have either an opalescent or translucent base, and is overlaid with pieces and flakes of colored glass fused at a high temperature.

SAFETY CHECKLIST

• Always keep glass and chemicals in a safe place when not in use, out of the reach of children and animals.

• Always wear protective glasses or goggles when cutting, filing, or grinding glass.

• Wear rubber or protective gloves when working with chemicals such as patina and etching cream.

• Always have a dustpan and brush handy, and frequently brush away the small slivers and shards of glass that accumulate on the work surface. Never use your bare hands to sweep away pieces of glass.

• Dispose of glass carefully. If it is going into a trashcan, put it in thick cardboard boxes first.

• Keep your work area tidy.

• Never attempt to catch a piece of falling glass.

• Hold the soldering iron by the handle only.

• Work in a well-ventilated area when soldering.

• Use a metal stand to rest the soldering iron on when in use, and switch it off when it is not in use.

• Keep a first aid kit handy.

• Always wash your hands before eating after handling lead, solder, or any chemicals.

Glass Accessories

Nuggets

Nuggets

These are thick, rounded pieces of colored or clear glass with a flattened side, resembling flattened glass marbles, that are available in various sizes. Nuggets can be foiled (see below left) and incorporated into panels, windows, and lamps.

Foiled nugget

Roundels

Roundels

These are round, machine-pressed or hand-spun pieces of glass with a smooth edge. They can be foiled or leaded and included in lamps, window panels, and three-dimensional projects.

Bevels

Bevels

These are clear shapes of glass with smooth, polished, beveled edges. Available in a variety of shapes and sizes, they may be foiled or leaded and incorporated into window panels. See here for a delicate design using clear bevels and glass.

Tools and Equipment

First of all, know this: you are going to see a lot of unfamiliar terms used to explain the tools and equipment needed for working with stained glass. Don’t panic! Everything is either explained within the tool descriptions or within the cutting instructions (here) or assembly instructions (here). Once you have read the entire Getting Started section, you will understand how the different tools are used to achieve different things.

To get you started, though, keep the following basics in mind. You cut glass by making a score in it, then breaking it. You assemble stained glass pieces by either soldering with copper foil or soldering with lead—both being types of metal added between pieces of glass to fuse them together.

Work Surface

You can work on any steady table with an even surface with plenty of space around you. If you are not working on a dedicated workbench, cover the tabletop with lots of newspaper to protect its surface. When cutting glass, use thick paper or felt to cover the table. Always keep a dustpan and brush handy to sweep up the thin slivers of glass frequently.

Glass Cutters

To make any stained glass project, you will need to cut glass into specific shapes. There are several varieties of glass cutters on the market, and new ones are continually being developed. You can even get specialized cutting tools like circle cutters. Avoid the cheap cutters you may find in a local hardware store; instead, invest in a good-quality cutter from a stained glass supplier. Here are three common types of glass cutters. You will only need one.

CARBIDE STEEL WHEEL CUTTER

This cutter usually has a ball shape on the end of the handle that is used for tapping the scored glass (see here). Some cutters have a replaceable cutting wheel. To prolong the wheel’s life, keep a jar with a cotton pad soaked in cutting oil and occasionally dip the wheel into it.

TUNGSTEN CARBIDE WHEEL CUTTER

This type of cutter usually has a built-in oil reservoir in the handle. It is more expensive than a steel wheel cutter, but it has a longer handle that most people find more comfortable to use, especially those new to the craft.

PISTOL GRIP CUTTER

This is the same type of tool as the tungsten carbide wheel cutter, but with a differently shaped handle.

Cutting Oil

This is useful for prolonging the life of a glass cutter and improving your score.

Cutting Square

This is used to score straight lines and to make sure that right angles are precise. The lip on the lower edge of the cutting square pictured (see here) helps when squaring off glass at a perfect right angle, whereas the long side of the square is used with a glass cutter for scoring straight lines.

Pliers

Pliers for glass work should not be confused with ordinary household pliers.

GROZER/BREAKER PLIERS

Specifically designed for working with glass, grozer/breaker pliers or combination pliers have curved jaws for gripping glass and can be used both for breaking glass and for nipping off small, irregular points from the edges of glass. The insides of the jaws are serrated and can be used to groze off slivers of glass remaining on the edges after breaking.

RUNNING PLIERS

These plastic or metal pliers are designed for breaking long, narrow sections of glass.

Silicon Carbide Stone

Sharp edges on glass can be removed by rubbing them on this natural stone (sometimes called a carborundum stone) prior to copper foiling (see here, step 4).

Electric Glass Grinder

You may wish to invest in this piece of equipment once you have some experience with glass work. This machine has a water-cooled grinding head that will not only rapidly blunt the sharp edges of the glass, but can also be used to grind away sections of glass (not pictured).

Soldering Iron

Soldering is the process of joining two metals together and is necessary for both copper foil work and lead work. Soldering is when you melt solder with a soldering iron to create a bond. You will need a soldering iron specifically designed for stained glass work, with a minimum of 75 watts. Small soldering irons used for electrical repairs will not be suitable. Always acquire a stand for the iron when making your purchase.

Solder

Solder is a mixture of tin and lead and is available in lengths (sticks) or by the roll. The combination can be 50 / 50 tin/lead or 60 / 40 tin/lead. Solder with a higher tin content will have a lower melting point, will flow quicker, and will have a more silvery finish. Lead-free solder is also available in 1 lb. (500 g) rolls. You may wish to use this for making jewelry.

Flux

Flux is necessary to allow the melted solder to flow easily while bonding as it is melted with a soldering iron. It is applied before soldering begins. It is available as a liquid or paste for copper foil work, or more rarely as a solid substance called solid flux or tallow candle for lead work. The liquid or paste is usually applied using a flux brush.

Cleaning the tip

Tip Cleaner

As you solder, black deposits will accumulate on the tip of the soldering iron. While you can clean the tip from time to time by wiping it on the sponge of the iron rest (see below), you should also use a chemical tip cleaner that will remove the deposits and enable the iron to transfer heat more efficiently (not pictured).

Copper Foil

Copper foil is a thin copper “tape” with an adhesive backing. It is wrapped around glass edges prior to soldering. It comes in a variety of widths; which width you will want to use will depend on the thickness and size of the piece of glass. Where two pieces of copper foiled glass are placed together and soldered, the resulting seam of solder will be wider or narrower depending on the width of the copper foil. Extremely versatile and suitable for both small and large window panels, copper foil is especially useful for three-dimensional items.

Patina

Patina is a liquid that can be applied to the solder of a finished project to turn the silver-colored solder either a gray/black or copper color. Rubber gloves must be worn when applying patina, and the project must be washed well in warm, soapy water and rinsed thoroughly with clean water afterwards.

Fid

This plastic or wooden implement is amazingly useful. It is used to press and smooth down copper foil onto the sides and edges of glass before soldering. Fids with a claw shape on one end are also used for prying open crushed channels of lead cames.

Lead Cames

Leading, a different technique than copper foiling, requires lead cames. Lead cames are strips of lead with an empty channel along each side for holding the glass. They come in lengths of 5 ft. 7 in. (1.7m) and 6 ft. 7 in. (2m) and in a variety of widths and profiles. For the leaded panel on here, a 1/4" (6mm) round lead came was used for the internal leading and a 1/2" (12mm) flat lead came for the perimeter.

Lead Vise

It is essential to straighten out any bends and kinks in a piece of lead before use. The lead vise should be affixed to a sturdy table or workbench and one end of the lead clamped into the vise. The other end of the length of lead should be held with pliers and tugged gently to stretch and straighten it. Alternatively, two people can stretch a piece of lead by holding one end each with a set of pliers. Be careful, though: if you pull too hard on the lead, you may find yourself flying backwards if the lead snaps. Short, gentle tugs are sufficient.

Lead Knife

This knife has a curved blade that cuts through lead cames. The heavy handle is useful for tapping in horseshoe nails.

Lead dyke