147,99 €

Mehr erfahren.

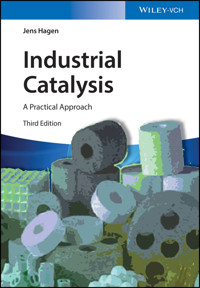

- Herausgeber: Wiley-VCH

- Kategorie: Wissenschaft und neue Technologien

- Sprache: Englisch

Now in it's 3rd Edition, Industrial Catalysis offers all relevant information on catalytic processes in industry, including many recent examples. Perfectly suited for self-study, it is the ideal companion for scientists who want to get into the field or refresh existing knowledge.

The updated edition covers the full range of industrial aspects, from catalyst development and testing to process examples and catalyst recycling. The book is characterized by its practical relevance, expressed by a selection of over 40 examples of catalytic processes in industry. In addition, new chapters on catalytic processes with renewable materials and polymerization catalysis have been included. Existing chapters have been carefully revised and supported by new subchapters, for example, on metathesis reactions, refinery processes, petrochemistry and new reactor concepts.

"I found the book accesible, readable and interesting - both as a refresher and as an introduction to new topics - and a convenient first reference on current industrial catalytic practise and processes."

Excerpt from a book review for the second edition by P. C. H. Mitchell, Applied Organometallic Chemistry (2007)

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 756

Veröffentlichungsjahr: 2015

Ähnliche

Table of Contents

Cover

Related Titles

Title Page

Copyright

Preface to the Third Edition

Abbreviations

Chapter 1: Introduction

1.1 The Phenomenon Catalysis

1.2 Mode of Action of Catalysts

1.3 Classification of Catalysts

1.4 Comparison of Homogeneous and Heterogeneous Catalysis

Exercises

References

Chapter 2: Homogeneous Catalysis with Transition Metal Catalysts

2.1 Key Reactions in Homogeneous Catalysis

2.2 Catalyst Concepts in Homogeneous Catalysis

2.3 Characterization of Homogeneous Catalysts

Exercises

References

Chapter 3: Homogeneously Catalyzed Industrial Processes

3.1 Overview

3.2 Examples of Industrial Processes

3.3 Asymmetric Catalysis

3.4 Alkene Metathesis

3.5 Recycling of Homogeneous Catalysts

Exercises

References

Chapter 4: Biocatalysis

4.1 Introduction

4.2 Kinetics of Enzyme-Catalyzed Reactions

4.3 Industrial Processes with Biocatalysts

Exercises

References

Chapter 5: Heterogeneous Catalysis: Fundamentals

5.1 Individual Steps in Heterogeneous Catalysis

5.2 Kinetics and Mechanisms of Heterogeneously Catalyzed Reactions

5.3 Catalyst Concepts in Heterogeneous Catalysis

5.4 Catalyst Performance

5.5 Catalyst Deactivation

5.6 Regeneration and Recycling of Heterogeneous Catalysts

5.7 Characterization of Heterogeneous Catalysts

Exercises

References

Chapter 6: Catalyst Shapes and Production of Heterogeneous Catalysts

6.1 Introduction

6.2 Bulk Catalysts

6.3 Supported Catalysts

6.4 Shaping of Catalysts and Catalyst Supports

6.5 Immobilization of Homogeneous Catalysts

Exercises

References

Chapter 7: Shape-Selective Catalysis: Zeolites

7.1 Composition and Structure of Zeolites

7.2 Catalytic Properties of the Zeolites

7.3 Isomorphic Substitution of Zeolites

7.4 Metal-Doped Zeolites

7.5 Applications of Zeolites

Exercises

References

Chapter 8: Heterogeneously Catalyzed Processes in Industry

8.1 Overview

8.2 Examples of Industrial Processes – Bulk Chemicals

8.3 Fine Chemicals Manufacture

Exercises

References

Chapter 9: Refinery Processes and Petrochemistry

9.1 Hydrotreating

9.2 Catalytic Cracking

9.3 Hydrocracking

9.4 Catalytic Reforming

9.5 Alkylation

9.6 Hydroisomerization

9.7 Synthesis Gas and Hydrogen by Steam Reforming

9.8 Natural Gas Conversion to Fuels and Chemicals

9.9 Fischer–Tropsch Synthesis

9.10 Etherification Reactions

Exercises

References

Chapter 10: Electrocatalytic Processes

10.1 Comparison Between Electrocatalysis and Heterogeneous Catalysis

10.2 Electroorganic Syntheses

10.3 Electrocatalysis in Fuel Cells

Exercises

References

Chapter 11: Environmental Catalysis and Green Chemistry

11.1 Automotive Exhaust Catalysis

11.2 NO

x

Removal Systems

11.3 Catalytic Afterburning

11.4 Green Chemistry and Catalysis

Exercises

References

Chapter 12: Phase-Transfer Catalysis

12.1 Definition

12.2 Catalysts for PTC

12.3 Mechanism and Benefits of PTC

12.4 PTC Reactions

12.5 Selected Industrial Processes with PTC

Exercises

References

Chapter 13: Catalytic Processes with Renewable Materials

13.1 Biofuels

13.2 Biorefinery

13.3 Chemicals from Biomass

Exercises

References

Chapter 14: Polymerization Catalysis

14.1 Introduction

14.2 Fundamentals of Catalytical Polymerization Processes

14.3 Coordination Polymerization

14.4 Examples of Catalytical Polymerization Processes

Exercises

References

Chapter 15: Planning, Development, and Testing of Catalysts

15.1 Stages of Catalyst Development

15.2 Development of a Catalytical Process: Hydrogenation of Benzene to Cyclohexane

15.3 Selection and Testing of Catalysts in Practice

Exercises

References

Chapter 16: Catalysis Reactors

16.1 Plug Flow Reactor (PFR)

16.2 Continuous Stirred-Tank Reactor (CSTR)

16.3 Reactor Calculations

16.4 Two-Phase Reactors

16.5 Three-Phase Reactors

16.6 Reactors for Homogeneously Catalyzed Reactions

16.7 New Reactor Concepts

Exercises

References

Chapter 17: Economic Importance of Catalysts

References

Chapter 18: Future Development of Catalysis

18.1 Homogeneous Catalysis

18.2 Heterogeneous Catalysis

References

Solutions to the Exercises

Chapter 1

Chapter 2

Chapter 3

Chapter 4

Chapter 5

Chapter 6

Chapter 7

Chapter 8

Chapter 9

Chapter 10

Chapter 11

Chapter 12

Chapter 13

Chapter 14

Chapter 15

Chapter 16

Index

End User License Agreement

Pages

xv

xvi

xvii

xviii

xix

xx

xxi

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

81

82

83

84

85

86

87

88

89

90

91

92

93

94

95

96

97

98

99

100

101

102

103

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

130

131

132

133

134

135

136

137

138

139

140

141

142

143

144

145

146

147

148

149

150

151

152

153

154

155

156

157

158

159

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

202

203

204

205

206

207

208

209

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

247

248

249

250

251

252

253

254

255

256

257

258

259

260

261

262

263

264

265

266

267

268

269

270

271

272

273

274

275

276

277

278

279

280

281

282

283

284

285

286

287

288

289

290

291

292

293

294

295

296

297

298

299

300

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

316

317

319

320

321

322

323

324

325

326

327

328

329

330

331

332

333

335

336

337

338

339

340

341

342

343

344

345

346

347

348

349

350

351

353

354

355

356

357

358

359

361

362

363

364

365

366

367

368

369

370

371

372

373

374

375

376

377

378

379

381

382

383

384

385

386

387

388

389

390

391

392

393

395

396

397

398

399

400

401

402

403

404

405

406

407

408

409

410

411

412

413

414

415

416

417

418

419

420

421

422

423

424

425

426

427

428

429

430

431

433

434

435

436

437

438

439

440

441

442

443

444

445

446

447

448

449

450

451

452

453

454

455

456

457

459

460

461

462

463

464

465

466

467

468

469

470

471

472

473

474

475

476

477

478

479

480

481

482

483

484

485

486

487

488

489

490

491

492

493

494

495

496

497

498

499

500

501

502

503

504

505

506

507

508

509

510

511

512

513

514

515

516

517

518

519

520

521

522

Guide

Cover

Table of Contents

Preface

Begin Reading

List of Illustrations

Chapter 1: Introduction

Figure 1.1 Catalytic cycle.

Scheme 1.1 Parallel and sequential reactions.

Scheme 1.2 Reactions of synthesis gas.

Scheme 1.3 Classification of catalysts.

Chapter 2: Homogeneous Catalysis with Transition Metal Catalysts

Scheme 2.1 Tendency to undergo oxidative addition for the metals of groups 8–10.

Scheme 2.2 Course of a homogeneously catalyzed reaction according to the 16/18-electron rule.

Scheme 2.3 Cobalt-catalyzed hydroformylation of a terminal alkene in terms of the 16/18-electron rule.

Figure 2.1 Carbonylation of 1-decene in a high-pressure IR apparatus; catalyst [(PPh

3

)

3

CuCl]/tetramethylethylenediamine, solvent THF. Bands: (1) 2130 cm

−1

, dissolved CO; (2) 2060 cm

−1

, Cu(CO) complex; (3) 1710–1720 cm

−1

, aldehyde; and (4) 1640 cm

−1

, 1-decene.

Figure 2.2 Schematic of the high-pressure IR apparatus (University of Applied Sciences Mannheim). (1) Magnetic piston autoclave with recirculating pump; (2) heating strip; (3) microfilter; (4) high-pressure IR cuvette; and (5) magnetic coil.

Figure 2.3 Chemical shifts in

31

P NMR spectra of transition metal chelate rings with bidentate phosphines ([2], used with permission of Wiley-VCH).

Figure 2.4 Pd-catalyzed methoxycarbonylation of ethene, hydride cycle [2].

Figure 2.5

31

P NMR investigation of the Pd-catalyzed methoxycarbonylation of ethene ([2], used with permission of Wiley-VCH).

Chapter 3: Homogeneously Catalyzed Industrial Processes

Scheme 3.1 Homogeneous transition metal-catalyzed reactions carried out industrially [1].

Scheme 3.2 Mechanism of the hydroformylation of propene with [HRh(CO)(PPh

3

)

3

].

Figure 3.1 Ruhrchemie/Rhône-Poulenc process for the hydroformylation of propene.

Scheme 3.3 Carbonylation of methanol to produce acetic acid (Monsanto process).

Scheme 3.4 Mechanism for the oxidation of ethylene to acetaldehyde in the Wacker process (chloride ligands omitted).

Figure 3.2 Acetaldehyde production in the two-stage Wacker–Hoechst process.

Scheme 3.5 Proposed mechanism for the oxidation of cyclohexane via free radicals.

Scheme 3.6 Proposed mechanism for the palladium-catalyzed Suzuki coupling.

Figure 3.3 Biphasic system of the SHOP process.

Scheme 3.7 Block schematic of the SHOP process.

Scheme 3.8 Schematic of ethylene oligomerization with nickel complex catalysts.

Scheme 3.9 Telomerization of butadiene.

Scheme 3.10 Telomerization of butadiene with methanol.

Scheme 3.11 Hydrocyanation of butadiene.

Figure 3.4 Selection of chiral phosphine ligands.

Figure 3.5 Mn-salen (Jacobsen complex).

Scheme 3.12 Simplified mechanism of alkene metathesis.

Figure 3.6 Tungsten carbene complex.

Figure 3.7 Carbene complexes as metathesis catalysts [6].

Figure 3.8 Fluorous phosphine ligand.

Scheme 3.13 Rhodium-catalyzed coupling of ethylene and butadiene.

Chapter 4: Biocatalysis

Figure 4.1 Biocatalysis as an interdisciplinary area.

Figure 4.2 Lock and key model for enzyme–substrate interaction.

Figure 4.3 Effect of coenzyme during acetaldehyde reduction.

Figure 4.4 Normalized rate for an enzyme-catalyzed reaction.

Figure 4.5 Lineweaver–Burk plot [6].

Figure 4.6 Lineweaver–Burk plot for the urea reaction.

Figure 4.7 Biosynthetic route to aspartame.

Figure 4.8 Pilot scale enzyme membrane reactor for the production of l-amino acids (Degussa AG).

Figure 4.9 6-aminopenicillanic acid (6-APA)

Figure 4.10 Manufacturing active pharmaceutical ingredients at Macfarlan Smith (Johnson Matthey).

Figure 4.11 Herbicide Outlook™.

Chapter 5: Heterogeneous Catalysis: Fundamentals

Figure 5.1 Individual steps of a heterogeneously catalyzed gas-phase reaction.

Figure 5.2 Concentration–position curves in the film diffusion region (a), the pore diffusion region (b), and the kinetic region (c).

Figure 5.3 Dependence of effective reaction rate on temperature.

Figure 5.4 Langmuir isotherm.

Figure 5.5 Langmuir–Hinshelwood mechanism (schematic).

Figure 5.6 Limiting cases of a bimolecular gas-phase reaction according to the Langmuir–Hinshelwood mechanism.

Figure 5.7 Eley–Rideal mechanism (schematic).

Figure 5.8 Bimolecular gas-phase reaction with the Eley–Rideal mechanism.

Figure 5.9 Course of a heterogeneously catalyzed gas-phase reaction .

E

a,0

= activation energy of the homogeneous uncatalyzed gas-phase reaction;

E

a,1

= true activation energy;

E

a,2

= apparent activation energy of the catalyzed reaction; Z

1

= transition state of the gas-phase reaction; Z

2

= transition state of the surface reaction; and Δ

H

R

= reaction enthalpy.

Figure 5.10 Molecular chemisorption of ethylene on a Pt surface.

Figure 5.11 Potential energy and interatomic distances in the adsorption of hydrogen on nickel. Curve 1: physisorption (0.32 nm, ); curve 2: chemisorption (0.16 nm, );

E

D

= dissociation energy of H

2

(218 kJ mol

−1

); and

E

A

= activation energy for adsorption.

Figure 5.12 Dissociative adsorption of hydrogen on nickel surfaces.

Figure 5.13 Relative activity of metals for the decomposition of formic acid as a function of the heat of formation of the metal formates (volcano plot).

Scheme 5.1 Mechanism for the hydrogenation of an alkene [17].

Scheme 5.2 Mechanism for the hydrogenation of acetylene.

Figure 5.14 Lattice planes in a cubic lattice with Miller indices.

Figure 5.15 Neighboring atoms and free valences of nickel surfaces in the face-centered cubic (fcc) lattice.

Figure 5.16 Model of a single-crystal surface (BASF, Ludwigshafen, Germany).

Figure 5.17 Ethylene hydrogenation as a function of the metal–metal distance in the lattice [8].

Figure 5.18 Oxidation of CO on platinum surfaces.

Figure 5.19 Electron transfer between catalyst and substrate.

Figure 5.20 Acceptor and donor functions according to the band model: (a) no adsorption; (b) acceptor; and (c) donor

E

F,0

= Fermi level;

E

F

= Fermi energy.

Figure 5.21 Adsorption of hydrogen on copper–nickel alloys.

Figure 5.22 Specific activity of copper–nickel alloys for the dehydrogenation of cyclohexane and the hydrogenolysis of ethane to methane at 316 °C.

Figure 5.23 Intrinsic semiconductor with excitation energy.

Figure 5.24 Semiconductors and how they function: (a) n-type semiconductor and (b) p-type semiconductor.

Scheme 5.3

Figure 5.25 Relative activities of metal oxides in the decomposition of N

2

O [28].

Scheme 5.4 Hydrogenation of ethylene on ZnO.

Figure 5.26 Acid centers in Al

2

O

3

.

Figure 5.27 Mechanism of gas-phase dehydration of ethanol on aluminum oxide.

Figure 5.28 Important properties of an industrial catalyst.

Figure 5.29 Structure of supported catalysts (Fonds der Chemischen Industrie, Frankfurt am Main, Germany, Folienserie Katalyse Nr. 19).

Scheme 5.5 Reforming of

n

-hexane on a Pt/Al

2

O

3

supported catalyst.

Scheme 5.6 Reforming of methane with CO

2

on supported Rh/Al

2

O

3

catalysts [31].

Figure 5.30 The action of potassium promoters in the dissociative chemisorption of N

2

on iron catalysts.

Figure 5.31 Deactivation behavior of catalysts [6].

Figure 5.32 Mechanisms of catalyst deactivation (M = metal) [6].

Figure 5.33 Dehydrogenative coking.

Figure 5.34 Catalyst deactivation in reforming processes [8].

Figure 5.35 Catalyst regeneration and loss of activity during a process.

Scheme 5.7 Regeneration of naphtha reforming catalysts [36].

Figure 5.36 Instruments of catalyst investigation.

Figure 5.37 Pore size spectrum in a refinery catalysts (BASF SE Ludwigshafen, Germany) [38]. There could be three differentiated classes of pores with a very bright distribution: (a) a few fairly large cracks (∼100 µm), (b) fine channels between the grains (∼600 nm), and (c) very small pores (∼6 nm).

Figure 5.38 Typical isotherm for physisorption.

Figure 5.39 Sorptometer (Catalysis laboratory, Mannheim University of Applied Sciences, Germany).

Figure 5.40 Scheme of a TPD spectrum of ammonia desorbing from zeolite [41].

Figure 5.41 Principle of a device for temperature-programmed reduction (TPR) [4].

Figure 5.42 Agglomeration of platinum crystallites in a platinum/graphite catalyst: quantification of the process by XPS (top middle) and visualization by TEM (bottom) (BASF SE, Ludwigshafen, Germany).

Figure 5.43 Investigation of a catalyst surface in an ESCA apparatus (BASF SE, Ludwigshafen, Germany).

Figure 5.44 ESCA spectrum of an Ag/Al

2

O

3

supported catalyst [42].

Figure 5.45 ISS spectra of a new and used ethylene oxide catalyst [22].

Chapter 6: Catalyst Shapes and Production of Heterogeneous Catalysts

Figure 6.1 Various shaped catalyst bodies (BASF, Ludwigshafen, Germany).

Scheme 6.1 Preparation methods for solid catalysts.

Scheme 6.2 Production of a precipitated catalyst [6].

Figure 6.2 Production of noble metal catalysts at the company Degussa, Hanau-Wolfgang, Germany.

Figure 6.3 Steps in the preparation of a porous powder via the sol–gel method ([8], used with permission of Wiley-VCH).

Scheme 6.3 Manufacturing of zeolites.

Scheme 6.4 Production of supported metal catalysts by impregnation.

Figure 6.4 Principle of catalyst preparation by incipient wetness impregnation.

Figure 6.5 Influence of the rate of drying on the profile of pores and particles.

Figure 6.6 Cross section of a shell catalyst (magnification 18×). Influence of the shell thickness on the selectivity of acrolein synthesis (BASF, Ludwigshafen, Germany):

Figure 6.7 Different metal distributions in pellets of diameter 6 mm consisting of a metal on a support (Degussa, Hanau-Wolfgang, Germany). (a) Shell catalyst with normal shell thickness; (b) shell catalyst with an extremely thin shell; (c) shell catalyst with a thick shell; (d) impregnated catalyst; and (e) catalyst with ring distribution.

Figure 6.8 Modern catalyst production plant (BASF, Ludwigshafen, Germany).

Figure 6.9 Acidic ion-exchange resin.

Figure 6.10 Manufacturing extruded heavy duty diesel emission control catalysts in Redwitz, Germany (Johnson Matthey).

Chapter 7: Shape-Selective Catalysis: Zeolites

Figure 7.1 Truncated octahedra as structural units of zeolites. (a) Sodalite cage (β-cage) and (b) sodalite cage (schematic).

Figure 7.2 Framework structure of zeolite A with α-cage.

Figure 7.3 Y zeolite (faujasite).

Figure 7.4 Pentasil zeolite with channel structure.

Figure 7.5 Shape selectivity of zeolites with examples of reactions. (a) Reactant selectivity: cleavage of hydrocarbons. (b) Product selectivity: methylation of toluene. (c) Restricted transition state selectivity: disproportionation of

m

-xylene.

Figure 7.6 Calcination of an HY zeolite: equilibrium between Brønsted and Lewis acid centers [13].

Scheme 7.1 Bifunctionality of metal-doped zeolites: isomerization and hydrogenation.

Figure 7.7 Modification possibilities of zeolite catalysts.

Chapter 8: Heterogeneously Catalyzed Processes in Industry

Figure 8.1 Supported metal catalyst with large reaction surface (Doduco).

Figure 8.2 Catalytic afterburning of the off-gases from a cyclohexanone plant (BASF, Antwerp).

Scheme 8.1 Simplified mechanism of ammonia synthesis.

Scheme 8.2 Synthesis of ammonia from natural gas.

Scheme 8.3 Reaction steps in the hydrogenation of fats.

Scheme 8.4 Mechanism of methanol synthesis.

Figure 8.3 Methanol plant (BASF, Ludwigshafen, Germany).

Scheme 8.5 Oxidation of propene on various metal oxide catalysts.

Scheme 8.6 Oxidation of propene to acrolein on Bi/Mo catalysts [12].

Scheme 8.7 Postulated reaction mechanism for the ammoxidation of propene [10].

Figure 8.4 SOHIO process for the ammoxidation of propene.

Figure 8.5 HPPO process (BASF SE) [14].

Figure 8.6 Oxidation of butane to maleic anhydride in a fixed-bed reactor.

Figure 8.7 Areas of fine chemicals.

Scheme 8.8 Atom efficiency in acetophenone production [16].

Scheme 8.9 Influence of yield improvement in a multistep process.

Figure 8.8 Use of metal catalysis in fine chemical synthesis.

Figure 8.9 Operation of a continuous high-pressure hydrogenation plant (CATATEST plant, VINCI technologies, France; high-pressure laboratory, Mannheim University of Applied Sciences, Germany).

Figure 8.10 A hydrogenation catalyst is introduced into a pilot plant in order to test it under process-relevant conditions (BASF SE, Ludwigshafen, Germany).

Figure 8.11 Comparison of stoichiometric and catalytic routes in oxidation processes.

Chapter 9: Refinery Processes and Petrochemistry

Scheme 9.1 Catalytic processes in a petroleum refinery.

Figure 9.1 Scheme of a modern FCC process.

Figure 9.2 Cracker in Secunda (Sasol Ltd., South Africa).

Figure 9.3 Model of a typical hydrocracking catalysts system.

Scheme 9.2 Major reactions during catalytic reforming.

Figure 9.4 Reforming catalyst.

Figure 9.5 Scheme of a reforming process.

Scheme 9.3 Major reactions during steam reforming.

Figure 9.6 Catalytic steam reforming unit [13].

Scheme 9.4 Conversion of natural gas to fuels and chemical raw materials [13].

Scheme 9.5 Major reactions in Fischer–Tropsch synthesis.

Figure 9.7 Production of MTBE by catalytic distillation.

Chapter 10: Electrocatalytic Processes

Figure 10.1 Electrochemical asymmetric bishydroxylation using a double mediator system in the presence of chiral ligands.

Figure 10.2 Complete fuel cell system including gas processing.

Figure 10.3 Scheme of a PEM fuel cell.

Figure 10.4 Fuel cell device for education (Leybold Didactic; University of Applied Sciences Mannheim, Germany, Institute of Chemical Process Engineering).

Figure 10.5 Different reaction pathways for electrochemical oxygen reduction in acidic electrolytes [10].

Figure 10.6 Scheme of methanol oxidation on Pt catalysts [7].

Chapter 11: Environmental Catalysis and Green Chemistry

Figure 11.1 Conversion profile in a three-way-catalyst.

Figure 11.2 Automobile exhaust catalyst (Fonds der Chemischen Industrie, Frankfurt am Main, Germany, Folienserie Nr. 19, Katalyse).

Figure 11.3 Honeycomb catalysts for air purification (Süd-Chemie AG, Heufeld, Germany).

Figure 11.4 Conversion-temperature profiles for different SCR catalysts (BASF SE, Ludwigshafen, Germany) [9].

Figure 11.5 Action of a NO

x

-storage reduction catalyst.

Figure 11.6 Typical afterburning process of a hydrocarbon.

Figure 11.7 Scheme of a catalytic afterburning plant.

Figure 11.8 Structures of some ionic liquids.

Figure 11.9 Substitution of common solvents.

Chapter 12: Phase-Transfer Catalysis

Figure 12.1 Structures of phase-transfer catalysts.

Figure 12.2 The extraction mechanism of phase-transfer catalysis [4].

Chapter 13: Catalytic Processes with Renewable Materials

Scheme 13.1 Conversion of biomass to fuels and chemicals [4].

Figure 13.1 Distribution of renewable raw materials (total 180 billion t/a) across material groups [12].

Figure 13.2 Palm oil plantation in Costa Rica.

Scheme 13.2 Fuels by gasification of biomass.

Scheme 13.3 Lignocellulose feedstock biorefinery.

Scheme 13.4 Value-chains for the production of chemicals and end-products from biomass.

Scheme 13.5 Glucose as one of the platform chemicals from cellulose.

Scheme 13.6 5-HMF as a platform for chemicals.

Figure 13.3 Monoterpenes.

Chapter 14: Polymerization Catalysis

Figure 14.1 Isotactic and syndiotactic polypropylene.

Scheme 14.1 Polymerization of ethylene at a metal center (M).

Figure 14.2 Catalytic active metallocene complex.

Figure 14.3 DSM catalyst “Lovacat.”

Scheme 14.2 Comparison of polyethylene types.

Figure 14.4 Gas-phase process for HDPE.

Scheme 14.3 Ziegler polymerization of ethylene with Ti/Al catalysts.

Chapter 15: Planning, Development, and Testing of Catalysts

Figure 15.1 Main steps in catalyst development.

Scheme 15.1 Target quantities and influences on the choice of catalyst [3].

Figure 15.2 Hydrogenation of benzene to cyclohexane (IFP process) [1].

Scheme 15.2 Procedures for choosing a catalyst.

Figure 15.3 Scheme of a differential reactor.

Figure 15.4 Catalyst test reactors.

Figure 15.5 Jet-loop reactor for catalyst investigations (high-pressure laboratory, Mannheim University of Applied Sciences, Germany). (1) Thermal mass flow controller (up to 200 bar); (2) nozzle, interchangeable; (3) catalyst pellets on wire mesh; (4) central tube; (5) heating band 500 W; (6) microfilter; (7) precision feed valve; (8) supplementary heating; and (9) gas meter.

Figure 15.6 Jet loop reactor (high-pressure laboratory, Mannheim University of Applied Sciences, Germany).

Figure 15.7 Gas chromatogram of methanol synthesis in the jet-loop reactor. Reaction conditions: , 40 bar, 25 g catalyst, , nozzle diameter 0.1 mm.

Figure 15.8 Industrial catalyst test center (Süd-Chemie AG, Heufeld, Germany).

Figure 15.9 Evaluation of the data from an integral reactor.

Figure 15.10 Polynomial fit of

X

A

versus

TF

(example integral reactor).

Figure 15.11 Kinetic study of the hydrogenation of benzaldehyde in a stirred autoclave operating in suspension mode [15].

Figure 15.12 Hydrogenation of benzaldehyde in a stirred autoclave: dependence of reaction rate on H

2

pressure [15].

Figure 15.13 Residence time spectra in a trickle-bed reactor as a function of liquid flow (LF) [18]. Reactor length 1 m, diameter, 25.4 mm, Cu/Zn mixed-oxide catalyst (tablets 6 × 3 mm), liquid phase

tert

-butanol, gas flow 10 l min

−1

, 100 bar H

2

pressure, 25 °C.

Figure 15.14 ISIM program for the simulation of a trickle-bed reactor for the high-pressure hydrogenation of a lactone [18].

Figure 15.15 Lactone hydrogenation in a trickle-bed reactor: conversion profiles as a function of liquid flow at constant liquid holdup [18].

Figure 15.16 Lactone hydrogenation in a trickle-bed reactor: conversion profiles taking into account the external liquid holdup [18].

Figure 15.17 Lactone hydrogenation in a trickle-bed reactor: conversion profiles as a function of liquid flow and reactor length [18].

Figure 15.18 Lactone hydrogenation in a trickle-bed reactor: conversion profiles as a function of the global mass-transfer coefficient of hydrogen [18].

Figure 15.19 Lactone hydrogenation in a trickle-bed reactor: reaction rate profiles as a function of mass transfer [18].

Figure 15.20 384-fold single-bead reactor employed at hte AG, Heidelberg, Germany.

Figure 15.21 Stage-II parallel high-pressure reactor system (hte AG, Heidelberg, Germany).

Chapter 16: Catalysis Reactors

Figure 16.1 Influences on the design of catalysis reactors.

Figure 16.2 Comparison of a continuous stirred tank reactor (CSTR) with a plug flow reactor (PFR).

Figure 16.3 Conversion down the packed bed.

Figure 16.4 Partial pressure ratio profiles.

Figure 16.5 Examples of important gas–solid reactors [2].

Figure 16.6 Miniplant unit for the development of catalytical processes in three-phase reactions (Evonik AG, Marl, Germany).

Figure 16.7 Three-phase reactors.

Figure 16.8 Pilot plant with 0.2 l trickle-bed reactor (Hoffmann-La Roche, Kaiseraugst, Switzerland).

Figure 16.9 Variants of the suspension reactor.

Figure 16.10 0.5 l stirred autoclave reactor in a high-pressure box (Mannheim University of Applied Sciences, Germany).

Figure 16.11 Principle of a membrane reactor.

Figure 16.12 Opened microreactor module used in the exothermic synthesis of an ionic liquid in 100 kg/d scale. Fraunhofer ICT-IMM, Mainz, Germany.

Chapter 17: Economic Importance of Catalysts

Figure 17.1 Worldwide catalyst market according to application [5].

Chapter 18: Future Development of Catalysis

Figure 18.1 CH activation of alkanes [3] L

n

M = catalyst (M = metal, L = ligand).

Figure 18.2 Development cycle of a product or process.

Figure 18.3 New catalysts – a key innovation in the future.

List of Tables

Chapter 1: Introduction

Table 1.1 History of the catalysis of industrial processes [3, 4]

Table 1.2

Table 1.3 Mole balance for methanol synthesis

Table 1.4 Comparison of homogeneous and heterogeneous catalysts

Table 1.5 Comparison of the key reactions of homogeneous and heterogeneous transition metal catalysis [12].

Chapter 2: Homogeneous Catalysis with Transition Metal Catalysts

Table 2.1 Typical cone angles for trivalent phosphorus ligands [9]

Table 2.2 Oxidative addition reactions on transition metal complexes; classification of the adding compounds

Chapter 3: Homogeneously Catalyzed Industrial Processes

Table 3.1 Industrial processes with homogeneous transition metal catalysis.

Table 3.2 Production of selected chemicals by homogeneous catalysis.

Table 3.3 Industrial propene hydroformylation processes [9]

Chapter 4: Biocatalysis

Table 4.1 Advantages and disadvantages of biocatalysts and enzymes [1]

Table 4.2 The six categories of enzymes according to the type of reaction [3]

Table 4.3 Acrylamide by chemical process and by biotransformation

Chapter 5: Heterogeneous Catalysis: Fundamentals

Table 5.1 Comparison of homogeneous and heterogeneous catalytic reactions

Table 5.2 Comparison of physisorption and chemisorption

Table 5.3 Examples of chemisorption processes

Table 5.4 IR bands of surface CO complexes on supported Ni catalysts

Table 5.5 IR bands of ethylene complexes

Table 5.6 Relative reaction rates on transition metal catalysts

Table 5.7 Structure and lattice spacings (distance to next-nearest neighbor in nm) of metals [20]

Table 5.8 Classification of metal-catalyzed reactions [1].

Table 5.9 Steric effects in chemical reactions.

Table 5.10 Adsorption and hydrogenation of ethylene on nickel surfaces [18]

Table 5.11 Classification of solid-state catalysts

Table 5.12 Relative catalytic activity of metals [9, 19, 20]

Table 5.13 Bimetallic catalysts in industrial processes.

Table 5.14 Hydrogenation of ethyl acetate to ethanol with Rh/Sn-SiO

2

catalysts [25].

Table 5.15 Hydrogenation of crotonaldehyde with bimetallic catalysts [26]

Table 5.16 Modification of the catalytic properties of the platinum group metals by addition of other metals [18]

Table 5.17 Excitation energies of semiconductors

Table 5.18 Behavior of nonstoichiometric semiconductor oxides

Table 5.19 Classification of the metal oxides according to their electronic properties.

Table 5.20 Oxidation of CO with metal oxide catalysts

Table 5.21 Decomposition of ethanol on semiconductor oxides

Table 5.22 Classification of acid/base catalysts [19]

Table 5.23 Performance of aluminum oxides in the dehydration of ethanol [29]

Table 5.24 Acidic catalysts for various reactions arranged in the order of increasing acidity [9]

Table 5.25 Important catalyst supports and their applications

Table 5.26 Selection of catalyst supports [20].

Table 5.27 Hydrogenolysis of ethane on supported nickel catalysts (10% Ni) [8]

Table 5.28 Dehydrogenation of cyclohexane to benzene on supported platinum catalysts at 773 K [30]

Table 5.29 Influence of support materials on the hydrogenation of CO with rhodium catalysts

Table 5.30 Examples of promoters in the chemical industry [19]

Table 5.31 Causes of deactivation in large-scale industrial processes

Table 5.32 Catalyst poisons and inhibitors in chemical processes [19]

Table 5.33 Recycling of precious metal catalysts [38]

Table 5.34 Specific surface areas of catalysts and support materials

Table 5.35 Specific chemisorption for the characterization of metal surfaces.

Table 5.36 Comparison of surface physics and industrial heterogeneous catalysis.

Chapter 6: Catalyst Shapes and Production of Heterogeneous Catalysts

Table 6.1 Shaping of catalysts

Table 6.2 Comparison of homogeneous and heterogenized catalysts in industrial reactions

Chapter 7: Shape-Selective Catalysis: Zeolites

Table 7.1 Characteristics of important zeolites.

Table 7.2 Molecular diameters and pore sizes of zeolites [1, 8]

Table 7.3 Constraint index (CI) for some typical catalysts at 316 °C [9]

Table 7.4 Relative rate of cleavage of heptanes on H-ZSM-5 at 325 °C [10]

Table 7.5 Product distribution in the ethylation of toluene [8]

Table 7.6 Effect of the metal ion in faujasite on the dealkylation of cumene [10]

Table 7.7 Classification of acidic zeolites according to increasing Si/Al ratio [6]

Table 7.8 Shape-selective hydrogenation [8]

Table 7.9 Important catalytic processes involving zeolites.

Table 7.10 Organic syntheses with zeolite catalysts [9, 7].

Chapter 8: Heterogeneously Catalyzed Processes in Industry

Table 8.1 Heterogeneous catalysis for the production of industrial gases and inorganic chemicals [3]

Table 8.2 Heterogeneously catalyzed processes for the production of organic chemicals [3]

Table 8.3 Heterogeneously catalyzed processes in refinery technology [3]

Table 8.4 Heterogeneous catalysts in environmental protection

Table 8.5 Fine versus bulk chemicals [16]

Table 8.6 Comparison of stoichiometric and catalytic reactions in fine chemicals synthesis [8]

Table 8.7

p

-Methoxyacetophenone via zeolite-catalyzed versus classical Friedel–Crafts acylation [16]

Chapter 9: Refinery Processes and Petrochemistry

Table 9.1 Process conditions and performance characteristics for hydrotreating of light and heavy feeds

Table 9.2 Propylene by FCC-based processes [7]

Table 9.3 Comparison of catalysts for C5–C6 hydroisomerization reactions

Table 9.4 Fixed-bed and fluidized-bed technologies in Fischer–Tropsch synthesis (wt%)

Chapter 10: Electrocatalytic Processes

Table 10.1 Types of fuel cell

Table 10.2 Electrocatalysts for the main fuel cell systems [9, 10]

Chapter 11: Environmental Catalysis and Green Chemistry

Table 11.1 Comparison of process temperatures for the oxidation of VOCs in afterburning processes

Table 11.2 Results of the aldol condensation with various catalysts [14]

Chapter 13: Catalytic Processes with Renewable Materials

Table 13.1 Derivatization reactions of fats and oils

Chapter 15: Planning, Development, and Testing of Catalysts

Table 15.1 Development of a catalyst for the oxidation of propene to acrolein [4]

Table 15.2 Catalyst screening.

Table 15.3 Hydrogenation of substituted 2-cyanonitro compounds [7].

Table 15.4 Catalyst screening in the hydrogenation of substituted 2-nitrobenzonitrile.

Table 15.5 Solvent screening in the hydrogenation of substituted 2-nitrobenzonitrile.

Table 15.6

Table 15.7 Hydrogenation of benzaldehyde in a trickle-bed reactor: measured values and model calculations [15]

Table 15.8 Measured and calculated conversion in the trickle-bed reactor; influence of the external holdup

Table 15.9 Stages I and II technologies for high-throughput experimentation [19]

Chapter 16: Catalysis Reactors

Table 16.1 Comparison of trickle-bed and suspension reactors

Table 16.2 Various technologies for the hydrogenation of adiponitrile [4]

Related Titles

Beller, M., Renken, A., van Santen, R.A. (eds.)

Catalysis

From Principles to Applications

2012

Print ISBN: 978-3-527-32349-4

Baerns, M., Behr, A., Brehm, A., Gmehling, J., Hofmann, H., Onken, U., Renken, A., Hinrichsen, K., Palkovits, R.

Technische Chemie

Second Edition2013

Print ISBN: 978-3-527-33072-0 Adobe PDF ISBN: 978-3-527-67407-7 eMobi ISBN: 978-3-527-67408-4 ePub ISBN: 978-3-527-67409-1

Bartholomew, C.H., Farrauto, R.J.

Fundamentals of Industrial Catalytic Processes, Second Edition

Second Edition 2006

Print ISBN: 978-0-471-45713-8 Adobe PDF ISBN: 978-0-471-73006-4 ISBN: 978-0-471-73007-1 eMobi ISBN: 978-1-118-20971-4 ePub ISBN: 978-1-118-20973-8

Jess, A., Wasserscheid, P.

Chemical Technology

An Integral Textbook

2013

Print ISBN: 978-3-527-30446-2 Vital eBook PDF ISBN: P-010-17008-4 eMobi ISBN: 978-3-527-67060-4 ePub ISBN: 978-3-527-67061-1 Adobe PDF ISBN: 978-3-527-67062-8 Vital eBook XML ISBN: 978-3-527-67501-2 CourseSmart ISBN: 978-3-527-67502-9

Wittcoff, H.A., Reuben, B.G., Plotkin, J.S.

Industrial Organic Chemicals, Third Edition

Third Edition2012

Print ISBN: 978-0-470-53743-5 Adobe PDF ISBN: 978-1-118-22981-1 ePub ISBN: 978-1-118-22987-3 eMobi ISBN: 978-1-118-22998-9 Adobe PDF ISBN: 978-1-118-22999-6

Arpe, H.

Industrielle Organische Chemie

Bedeutende Vor- und Zwischenprodukte

Sixth Edition 2007

Print ISBN: 978-3-527-31540-6

Arpe, H.

Industrial Organic Chemistry

Fifth Edition 2010

Print ISBN: 978-3-527-32002-8

Bertau, M., Müller, A., Fröhlich, P., Katzberg, M.

Industrielle Anorganische Chemie

Fourth Edition 2013

Print ISBN: 978-3-527-33019-5 ISBN: 978-3-527-64956-3 eMobi ISBN: 978-3-527-64957-0 ePub ISBN: 978-3-527-64958-7 Adobe PDF ISBN: 978-3-527-64959-4

Blaser, H., Federsel, H. (eds.)

Asymmetric Catalysis on Industrial Scale

Challenges, Approaches and Solutions

Second Edition 2010

Print ISBN: 978-3-527-32489-7 ISBN: 978-3-527-63063-9 Adobe PDF ISBN: 978-3-527-63064-6 ePub ISBN: 978-3-527-64216-8 eMobi ISBN: 978-3-527-64217-5

Soetaert, W., Vandamme, E.J. (eds.)

Industrial Biotechnology

Sustainable Growth and Economic Success

2010

Print ISBN: 978-3-527-31442-3 ISBN: 978-3-527-63023-3 Adobe PDF ISBN: 978-3-527-63024-0

Moulijn, J.A., Makkee, M., van Diepen, A.E.

Chemical Process Technology 2e

Second Edition 2013

Print ISBN: 978-1-444-32024-4 eMobi ISBN: 978-1-118-57073-9 Adobe PDF ISBN: 978-1-118-57074-6 ePub ISBN: 978-1-118-57075-3 Vital eBook XML ISBN: 978-1-118-57076-0 CourseSmart ISBN: 978-1-118-57077-7

Maitlis, P.M., de Klerk, A. (eds.)

Greener Fischer-Tropsch Processes

For Fuels and Feedstocks

2013

Print ISBN: 978-3-527-32945-8 ISBN: 978-3-527-65683-7 eMobi ISBN: 978-3-527-65684-4 ePub ISBN: 978-3-527-65685-1 Adobe PDF ISBN: 978-3-527-65686-8

de Klerk, A.

Fischer-Tropsch Refining

2011

Print ISBN: 978-3-527-32605-1 ISBN: 978-3-527-63560-3 ePub ISBN: 978-3-527-63561-0 Adobe PDF ISBN: 978-3-527-63562-7 eMobi ISBN: 978-3-527-63563-4

Behr, A., Neubert, P.

Applied Homogeneous Catalysis

2012

Print ISBN: 978-3-527-32633-4

Jens Hagen

Industrial Catalysis

A Practical Approach

Third Completely Revised and Enlarged Edition

The Author

Prof. Dr. Jens Hagen

Johannes-Brahms-Str. 2

76684 Östringen

Germany

All books published by Wiley-VCH are carefully produced. Nevertheless, authors, editors, and publisher do not warrant the information contained in these books, including this book, to be free of errors. Readers are advised to keep in mind that statements, data, illustrations, procedural details or other items may inadvertently be inaccurate.

Library of Congress Card No.: applied for

British Library Cataloguing-in-Publication Data

A catalogue record for this book is available from the British Library.

Bibliographic information published by the Deutsche Nationalbibliothek

The Deutsche Nationalbibliothek lists this publication in the Deutsche Nationalbibliografie; detailed bibliographic data are available on the Internet at <http://dnb.d-nb.de>.

© 2015 Wiley-VCH Verlag GmbH & Co. KGaA, Boschstr. 12, 69469 Weinheim, Germany

All rights reserved (including those of translation into other languages). No part of this book may be reproduced in any form – by photoprinting, microfilm, or any other means - nor transmitted or translated into a machine language without written permission from the publishers. Registered names, trademarks, etc. used in this book, even when not specifically marked as such, are not to be considered unprotected by law.

Print ISBN: 978-3-527-33165-9

ePDF ISBN: 978-3-527-68465-6

ePub ISBN: 978-3-527-68464-9

Mobi ISBN: 978-3-527-68463-2

oBook ISBN: 978-3-527-68462-5

Preface to the Third Edition

Since the second edition of this book the field of industrial catalysis has made significant progress. New techniques in catalyst development have become relevant and many new processes were introduced in industry. The focus of this textbook is still to cover the fundamentals of homogeneous, heterogeneous catalysis, and biocatalysis, and to describe the industrial practice of catalysis and some special topics of applied catalysis.

The third edition has been extensively revised and updated. From the wealth of catalytical processes, a selection had to be made. Knowledge of some key processes is essential for the understanding of catalysis.

Entirely new are the chapters and sections.

refinery processes and petrochemistry;

catalytic processes with renewable materials;

polymerization catalysis;

catalyst shapes and production of heterogeneous catalysts;

recycling of homogeneous catalysts;

regeneration and recycling of heterogeneous catalysts;

new reactor concepts.

In some other sections, additional examples of catalytical processes are addressed, for instance, alkene metathesis, telomerization of butadiene, adipodinitrile, maleic anhydride and phthalic anhydride, propylene oxide, pharmaceuticals, and fine chemicals. Many new exercises including solutions were added, they should help users develop a better understanding of the material.

The book is largely the result of courses for chemical engineers I have given at the Mannheim University of Applied Sciences, some universities abroad, and several vocational training seminars for chemists and engineers in industry. I hope that this edition will still be useful to students and to engineers, chemists, and professionals who work in the chemical industry and related industries. The book is particularly well suited for the self-study of people who have a basic knowledge of chemistry and chemical reaction engineering.

My great appreciation is given to the following companies and institutions, which provided new pictures for this edition: BASF SE, Ludwigshafen; Johnson Matthey Plc, London, UK; Sasol Ltd., South Africa; Fonds der Chemischen Industrie, Frankfurt am Main; Chemieanlagenbau Chemnitz GmbH, Evonik Services GmbH, Hanau-Wolfgang; Fraunhofer ICT-IMM, Mainz.

I would like to thank the production team at Wiley-VCH, particularly Dr. Elke Maase and the editors Dr. Claudia Ley and Stefanie Volk for their kind assistance and support.

Furthermore, I am grateful for the many helpful comments by the coworkers of SPi Global during typesetting. Finally, I thank my wife Julia again for her pacience and understanding during realization of this project.

I hope that the reader will see that catalysis is one of the most exciting areas in chemistry.

Jens Hagen

Östringen

April 2015

Abbreviations

A

area (m

2

)

A

*

adsorbed (activated) molecules of component

A

a

catalyst activity

a

s

area per mass (m

2

kg

−1

)

A

electron acceptor

Ac

acetyl CH

3

CO-

AAS

atomic absorption spectroscopy

ADH

alcohol dehydrogenase enzyme

ADMET

acyclic diene metathesis

6-APA

6-aminopenicillanic acid

ads

adsorbed (subscript)

AES

Auger electron spectroscopy

aq

aqueous solution (subscript)

bcc

body-centered cubic

bipy

2,2′-bipyridine

Bu

butyl C

4

H

9

-

BET

Brunauer, Emmet, and Teller (adsorption process)

c

i

concentration of component

i

(mol l

−1

)

CB

conduction band

C.I.

constraint index

CMR

catalytical membrane reactor

Cp

cyclopentadienyl C

5

H

5

-

CSTR

continuous stirred tank reactor

D

diffusion coefficient (m

2

s

−1

)

d

deactivation (subscript)

D

electron donor

DMFC

direct methanol fuel cell

DMSO

dimethyl sulfoxide

DVB

divinylbenzene

E

E factor, rate of waste (kg) per product unit (kg)

E

a

activation energy (J mol

−1

)

E

F,0

Fermi level

E

enzyme

ee

enantiomeric excess (%)

eff

effective (subscript)

E

i

ionization energy

E

r

redox potential (V)

Et

ethyl C

2

H

5

-

ESCA

electron spectroscopy for chemical analysis

ESR

electron spin resonance spectroscopy

ETBE

ethyl

tert

-butyl ether

e

electrons

F

Faraday constant (96 485 C mol

−1

)

fcc

face-centered cubic

FCC

fluid catalytic cracking

Δ

G

Gibb's free energy (J mol

−1

)

G

gas (subscript, too)

GDP

gross domestic product

GHSV

gas hourly space velocity (h

−1

)

GTL

gas to liquids

H

Henry's law constant

H

ex

external holdup

Δ

H

ads

adsorption enthalpy (J mol

−1

)

Δ

H

f

enthalpy change of formation (J mol

−1

)

H

m

modified Henry's law constant

Δ

H

R

reaction enthalpy (J mol

−1

)

HC

hydrocarbon

HDN

hydrodenitrogenation

HDPE

high-density polyethylene

HDS

hydrodesulfurization

5-HMF

5-hydroxymethylfurfural

HPA

heteropolyacids

HPPO

hydrogen peroxide to propylene oxide

hcp

hexagonal close packing

i

intrinsic

I

inhibitor

ICP

inductively coupled plasma

IL

ionic liquid

ISS

ion-scattering spectroscopy

K

equilibrium constant

K

i

adsorption equilibrium constant of component

i

K

i

inhibition constant

K

M

Michaelis constant

k

reaction rate constant

k

0

pre-exponential factor

k

L

a

L

gas–liquid mass transfer coefficient

k

S

a

S

liquid–solid mass transfer coefficient

k

tot

global mass transfer coefficient

L

liquid (subscript)

L

ligand

LCF

lignocellulose feedstock

LDPE

low-density polyethylene

l-DOPA

2-amino-3-(3,4-dihydroxyphenyl)propionic acid

LEED

low-energy electron diffraction

LHSV

liquid hourly space velocity (h

−1

)

LLDPE

linear low-density polyethylene

LPG

liquefied petrol gas

LSR

light straight run (naphtha)

LF

liquid feed (l min

−1

)

M

metal

m

mass (kg)

m

cat.

mass of catalyst (kg)

MA

maleic anhydride

MAO

methylaluminoxane

MCM-41

mesoporous material

MSR

microstructured reactor

MTG

methanol to gasoline

MTO

methanol to olefins

MTBE

methyl

tert

-butyl ether

MTP

methanol to propylene

MWD

molecular weight distribution

Me

methyl CH

3

-

n

number of moles (mol)

n

order of reaction

n

degree of polymerization

flow rate (mol s

−1

)

feed flow rate of starting material A (mol s

−1

)

NAD

nicotinamide adenine dinucleotide cofactor

NSR

NO

x

storage reduction

OCS

oxygen storage component

ODE

ordinary differential equation

ON

octane number

Oxad

oxidative addition

P

total pressure (bar)

PA

phthalic anhydride

PE

polyethylene

PEG

polyethylene glycol

PEMFC

proton exchange membrane fuel cell

PFR

plug flow reactor

PP

polypropylene

PVI

pore volume impregnation

Ph

phenyl C

6

H

5

-

PPh

3

triphenylphosphine

PTC

phase-transfer catalysis

p

pressure (bar)

p

i

partial pressure of component

i

(bar)

py

pyridine

R

ideal gas law constant (J mol

−1

K

−1

)

R

recycle ratio

R

alkyl

RCM

ring-closing metathesis

ROMP

ring-opening metathesis polymerization

RON

research octane number

RTD

residence time distribution

r

reaction rate (mol l

−1

h

−1

)

r

eff

effective reaction rate per unit mass of catalyst (mol kg

−1

h

−1

)

rel

relative (subscript)

r

d

deactivation rate

S

surface area (m

2

kg

−1

)

Δ

S

entropy change (J mol

−1

K

−1

)

S

p

selectivity (mol mol

−1

) or (%)

S

solid (subscript, too)

SCR

selective catalytic reduction

SIMS

secondary-ion mass spectroscopy

SLPC

supported liquid-phase catalysts

SMSI

strong metal-support interaction

SSPC

supported solid-phase catalysts

STEM

scanning transmission electron microscopy

S

−1

mass index, ratio of all the materials (kg) to the product (kg)

S

substrate

sc

supercritical

STY

space time yield (mol l

−1

h

−1

, kg l

−1

h

−1

)

T

temperature (K)

TAME

tert

-amyl methyl ether

TBGE

tert

-butylglycerol ether

TEM

transmission electron microscopy

TF

time factor

TOF

turnover frequency (s

−1

)

TON

turnover number (mol mol

−1

s

−1

)

t

time (s, h)

TPD

temperature-programmed desorption

TPPMS

triphenylphosphine monosulfonate

TPPTS

triphenylphosphine trisulfonate

TPR

temperature-programmed reduction

TS 1

titanium(IV) silicalite zeolite catalyst

TWC

three-way catalyst

U

cell voltage (V)

V

volume (m

3

)

volumetric flow rate

V

R

reaction volume (m

3

)

VB

valence band

VGO

vacuum gas oil

VOC

volatile organic compound

VPO

vanadium–phosphorous oxide

WGS

water gas shift (reaction)

WHSV

weight hourly space velocity (kg kg

cat

−1

h

−1

or h

−1

)

X

conversion (mol mol

−1

) or (%)

XPS

X-ray photoelectron spectroscopy

XRD

X-ray diffraction

z

tube length (m)

void fraction of particle

λ

air/fuel intake ratio for gasoline engines

η

catalyst effectiveness factor

η

overpotential (V)

θ

i

degree of coverage of the surface of component

i

v

stretching frequencies (IR) (cm

−1

)

v

i

stoichiometric coefficient

ρ

density (g ml

−1

)

ρ

cat.

pellet density of the catalyst (g ml

−1

)

τ

tortuosity

σ

interfacial tension

φ

0

work function (eV)

*

active centers on the catalyst surface

Chapter 1Introduction

1.1 The Phenomenon Catalysis

Catalysis is the key to chemical transformations. Most industrial syntheses and nearly all biological reactions require catalysts. Furthermore, catalysis is the most important technology in environmental protection, that is, the prevention of emissions. A well-known example is the catalytic converter for automobiles.

Catalytic reactions were already used in antiquity, although the underlying principle of catalysis was not recognized at the time. For example, the fermentation of sugar to ethanol and the conversion of ethanol to acetic acid are catalyzed by enzymes (biocatalysts). However, the systematic scientific development of catalysis only began about 200 years ago, and its importance has grown up to the present day [1].

The term “catalysis” was introduced as early as 1836 by Berzelius in order to explain various decomposition and transformation reactions. He assumed that catalysts possess special powers that can influence the affinity of chemical substances.

A definition that is still valid today is due to Ostwald (1895): “a catalyst accelerates a chemical reaction without affecting the position of the equilibrium.” Ostwald recognized catalysis as a ubiquitous phenomenon that was to be explained in terms of the laws of physical chemistry.

While it was formerly assumed that the catalyst remained unchanged in the course of the reaction, it is now known that the catalyst is involved in chemical bonding with the reactants during the catalytic process. Thus, catalysis is a cyclic process: the reactants are bound to one form of the catalyst, and the products are released from another, regenerating the initial state.

In simple terms, the catalytic cycle can be described as shown in Figure 1.1. The intermediate catalyst complexes are in most cases highly reactive and difficult to detect.

Figure 1.1 Catalytic cycle.

In theory, an ideal catalyst would not be consumed, but this is not the case in practice. Owing to competing reactions, the catalyst undergoes chemical changes, and its activity becomes lower (catalyst deactivation). Thus, catalysts must be regenerated or eventually replaced.

Apart from accelerating reactions, catalysts have another important property: they can influence the selectivity of chemical reactions. This means that completely different products can be obtained from a given starting material by using different catalyst systems. Industrially, this targeted reaction control is often even more important than the catalytic activity.

Catalysts can be gases, liquids, or solids. Most industrial catalysts are liquids or solids, whereby the latter react only via their surface. The importance of catalysis in the chemical industry is shown by the fact that 75% of all chemicals are produced with the aid of catalysts; in newly developed processes, the figure is over 90%. Numerous organic intermediate products required for the production of plastics, synthetic fibers, pharmaceuticals, dyes, crop protection agents, resins, and pigments can only be produced by catalytic processes [2].

Most of the processes involved in crude oil processing and petrochemistry, such as purification stages, refining, and chemical transformations, require catalysts. Environmental protection measures such as automobile exhaust control and purification of off-gases from power stations and industrial plant would be inconceivable without catalysts.

Catalysts have been successfully used in the chemical industry for more than 100 years, examples being the synthesis of sulfuric acid, the conversion of ammonia to nitric acid, and catalytic hydrogenation. Later developments include new highly selective multicomponent oxide and metallic catalysts, zeolites, and the introduction of homogeneous transition metal complexes in the chemical industry. This was supplemented by new high-performance techniques for probing catalysts and elucidating the mechanisms of heterogeneous and homogenous catalysis.

The brief historical survey given in Table 1.1 shows just how closely the development of catalysis is linked to the history of industrial chemistry [4].

Table 1.1 History of the catalysis of industrial processes [3, 4]

Catalytic reaction

Catalyst

Discoverer or company/year

Sulfuric acid (lead chamber process)

NO

x

Désormes, Clement, 1806

Chlorine production by HCl oxidation

CuSO

4

Deacon, 1867

Sulfuric acid (contact process)

Pt, V

2

O

5

Winkler, 1875; Knietsch, 1888 (BASF)

Nitric acid by NH

3

oxidation

Pt/Rh nets

Ostwald, 1906

Fat hardening

Ni

Normann, 1907

Ammonia synthesis from N

2

, H

2

Fe

Mittasch, Haber, Bosch, 1908; Production, 1913 (BASF)

Hydrogenation of coal to hydrocarbons

Fe, Mo, Sn

Bergius, 1913; Pier, 1927

Oxidation of benzene, naphthalene to maleic anhydride or phthalic anhydride

V

2

O

5

Weiss, Downs, 1920

Methanol synthesis from CO/H

2

ZnO/Cr

2

O

3

Mittasch, 1923

Hydrocarbons from CO/H

2

(motor fuels)

Fe, Co, Ni

Fischer, Tropsch, 1925

Oxidation of ethylene to ethylene oxide

Ag

Lefort, 1930

Alkylation of olefins with isobutane to gasoline

AlCl

3

Ipatieff, Pines, 1932

Cracking of hydrocarbons

Al

2

O

3

/SiO

2

Houdry, 1937

Hydroformylation of ethylene to propanal

Co

Roelen, 1938 (Ruhrchemie)

Cracking in a fluidized bed

Aluminosilicates

Lewis, Gilliland, 1939 (Standard Oil)

Ethylene polymerization, low pressure

Ti compounds

Ziegler, Natta, 1954

Oxidation of ethylene to acetaldehyde

Pd/Cu chlorides

Hafner, Smidt (Wacker)

Ammoxidation of propene to acrylonitrile

Bi/Mo

Idol, 1959 (SOHIO process)

Olefin metathesis

Re, W, Mo

Banks, Bailey, 1964

Hydrogenation, isomerization, hydroformylation

Rh and Ru complexes

Wilkinson, 1964

Asymmetric hydrogenation

Rh/chiral phosphine

Knowles, 1974; L-Dopa (Monsanto)

Three-way catalyst

Pt, Rh/monolith

General Motors, Ford, 1974

Methanol conversion to hydrocarbons

Zeolites

Mobil Chemical Co., 1975

α-Olefins from ethylene

Ni/chelate phosphine

Shell (SHOP process) 1977

Sharpless oxidation, epoxidation

Ti/ROOH/tartrate

May & Baker, Upjohn, ARCO, 1981

Selective oxidations with H

2

O

2

Titanium zeolite (TS-1)

Enichem, 1983

Hydroformylation

Rh/phosphine/aqueous

Rhône-Poulenc/Ruhrchemie, 1984

Polymerization of olefins

zirconocene/MAO

Sinn, Kaminsky, 1985

Selective catalytic reduction SCR (power plants)

V, W, Ti oxides/monolith

∼1986

Acetic acid

Ir/I

−

/Ru

“Cativa”-process, BP Chemicals, 1996

W.S. Knowles, R. Noyori, K.B. Sharpless

Ti compounds, diphosphine ligands

Nobel Prize for asymmetric catalysis, 2001

Y. Chauvin, R.S. Grubbs, R.R. Schrock,

Mo, Ru

Nobel Prize for studies of catalysis in metathesis, 2005

G. Ertl

–

Nobel Prize for chemical processes on solid surfaces, 2007

Propylene oxide from propylene and hydrogen peroxide

Ti-zeolite

BASF, Evonik/Uhde, 2008

R.F. Heck, A. Suzuki, E. Negishi

–

Nobel Prize for cross-couplings in organic synthesis, 2010

TS-1 = titanium (iv) silicalite zeolite catalyst, MAO = methylaluminoxane, and HPPO = hydrogen peroxide to propylene oxide.

1.2 Mode of Action of Catalysts

The suitability of a catalyst for an industrial process depends mainly on the following three properties:

activity

selectivity

stability (deactivation behavior).

The question which of these functions is the most important is generally difficult to answer because the demands made on the catalyst are different for each process. First, let us define the above terms [5, 6, 7, 8].

1.2.1 Activity

Activity is a measure of how fast one or more reactions proceed in the presence of the catalyst. Activity can be defined in terms of kinetics or from a more practically oriented viewpoint. In a formal kinetic treatment, it is appropriate to measure reaction rates in the temperature and concentration ranges that will be present in the reactor.

The reaction rate r is calculated as the rate of change of the amount of substance nA of reactant A with time relative to the reaction volume or the mass of catalyst:

Kinetic activities are derived from the fundamental rate laws, for example, that for a simple irreversible reaction :

k is the rate constant and f (cA) is a concentration term that can exhibit a first-order or higher order dependence on adsorption equilibria (see Section 5.2).

The temperature dependence of rate constants is given by the Arrhenius equation:

where Ea is the activation energy of the reaction; k0 is the pre-exponential factor; and R is the gas constant.

Equations (1.2) and (1.3) show that there are three possibilities for expressing catalyst activity, which are as follows:

reaction rate

rate constant

k

activation energy

E

a

.

Empirical rate equations are obtained by measuring reaction rates at various concentrations and temperatures. If, however, different catalysts are to be compared for a given reaction, the use of constant concentration and temperature conditions is often difficult because each catalyst requires it own optimal conditions. In this case, it is appropriate to use the initial reaction rates r0 obtained by extrapolation to the start of the reaction.

Another measure of catalyst activity is the turnover number (TON), which originates from the field of enzymatic catalysis.

In the case of homogeneous catalysis, in which well-defined catalyst molecules are generally present in solution, the TON can be directly determined. For heterogeneous catalysts, this is generally difficult, because the activity depends on the size of the catalyst surface, which, however, does not have a uniform structure. For example, the activity of a supported metal catalyst is due to active metal atoms dispersed over the surface.

The number of active centers per unit mass or volume of catalyst can be determined indirectly by means of chemisorption experiments, but such measurements require great care, and the results are often not applicable to process conditions. Although the TON appears attractive due to its molecular simplicity, it should be used prudently in special cases.

In practice, readily determined measures of activity are often sufficient. For comparative measurements, such as catalyst screening, determination of process parameters, optimization of catalyst production conditions, and deactivation studies, the following activity measures can be used:

conversion under constant reaction conditions;

space velocity for a given, constant conversion;

space–time yield;

temperature required for a given conversion.

Catalysts are often investigated in continuously operated test reactors, in which the conversions attained at constant space velocity are compared [5].

The space velocity is the volume flow rate , relative to the catalyst mass mcat:

The conversion XA is the ratio of the amount of reactant A that has reacted to the amount that was introduced into the reactor. For a batch reactor,

If we replace the catalyst mass in Eq. (1.4) with the catalyst volume, then we see that the space velocity is proportional to the reciprocal of the residence time.

Often the performance of a reactor is given relative to the catalyst mass or volume, so that reactors of different size or construction can be compared with one another. This quantity is known as the space–time yield (STY):

Determination of the temperature required for a given conversion is another method of comparing catalysts. The best catalyst is the one that gives the desired conversion at a lower temperature. This method cannot, however, be recommended since the kinetics are often different at higher temperature, making misinterpretations likely. This method is better suited to carrying out deactivation measurements on catalysts in pilot plants.

1.2.1.1 Turnover Frequency TOF

The turnover frequency (TOF) (the term was borrowed from enzyme catalysis) quantifies the specific activity of a catalytic center for a special reaction under defined reaction conditions by the number of molecular reactions or catalytic cycles occurring at the center per unit time. For heterogeneous catalysts, the number of active centers is derived usually from sorption methods (Eq. (1.7)).

For most relevant industrial applications, the TOF is in the range 10−2–102 s−1 (enzymes 103–107 s−1).

Examples:

TOF values for the hydrogenation of cyclohexene at 25 °C and 1 bar (supported catalysts, structure-insensitive reaction) are provided in Table 1.2).

Metal

TOF (s

−1

)

Gas phase

Liquid phase

Ni

2.0

0.45

Rh

6.1

1.3

Pd

3.2

1.5

Pt

2.8

0.6

1.2.1.2 Turnover Number TON

The TON specifies the maximum use that can be made of a catalyst for a special reaction under defined conditions by a number of molecular reactions or reaction cycles occurring at the reactive center up to the decay of activity. The relationship between TOF and TON is (Eq. (1.8))

For industrial applications the TON is in the range 106–107.

1.2.2 Selectivity

The selectivity SP