Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: Fox Chapel Publishing

- Kategorie: Lebensstil

- Serie: Home Machinists

- Sprache: Englisch

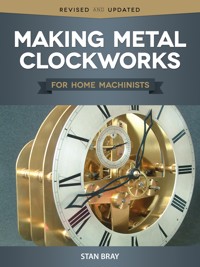

Revised and newly updated, Making Metal Clockworks is an introduction to horology for the complete beginner. Explaining the terminology and general forms of clock construction, you'll learn about the necessary tools, materials, and methods and understand everything from and the layout of wheels and escapements to the making of wheels, pinions, pendulums, and so much more. With insightful details of how to make specialized items and advice on the most suitable materials for their construction, this is the perfect introduction to the fascinating world of clockmaking.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 148

Veröffentlichungsjahr: 2021

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

MAKING METAL CLOCKWORKS

Stan Bray

© Stan Bray, 2001

Published in the UK by Special Interest Model Books, 2003

This edition published in 2020 by Fox Chapel Publishing, Inc., 903 Square Street, Mount Joy, PA 17552.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or transmitted, in any form or by any means, electronic, mechanical, photocopying, recording, or otherwise, without the prior written permission of the copyright holders.

Fox Chapel Publishing Project Team

Technical Editor: George Bulliss

Editor: Katie Ocasio

Layout: Christopher Morrison

Print ISBN 9781497100596

eISBN 9781607657309

The Cataloging-in-Publication Data is on file with the Library of Congress.

To learn more about the other great books from Fox Chapel Publishing, or to find a retailer near you, call toll-free 800-457-9112 or visit us at www.FoxChapelPublishing.com.

We are always looking for talented authors. To submit an idea, please send a brief inquiry to [email protected].

Contents

Introduction

Chapter 1—History

Chapter 2—The Frame

Chapter 3—Providing the Power

Chapter 4—Pendulums

Chapter 5—Escapements

Chapter 6—The Going Train and Motion Work

Chapter 7—Dividing

Chapter 8—Wheels and Pinions

Chapter 9—Finishing

Chapter 10—Faces, Hands, and Cases

Appendix

Introduction

Clockmaking appears to hold a fascination all of its own, particularly among model engineers, many deciding to make a clock after having made models of various types. There is something absolutely fascinating about clockmaking that seems to draw one toward it. This book is intended as a brief introduction to the tools, materials, and methods generally used and to offer an explanation of general forms of construction. It is not a book of plans, but those who have sufficient confidence could use the information it contains to make a simple clock.

Although clocks come in all sorts of shapes and sizes, the basic principle behind a mechanical clock has not changed for about five hundred years. Of course, modern materials and tools have superseded some of the older ones, but apart from this, the horologist will still tend to work in the traditional fashion.

Clockmaking has long been part of the model engineering hobby rather than being entirely the preserve of the horologist, and the type of workshop owned by the average model engineer is quite suitable for the work. Although a special workshop is not required, one thing that will not do is to work in a workshop that is full of swarf and other rubbish. Accepting that we cannot always have a clinically clean place in which to operate, particularly if it serves several purposes, it is still possible to make a clean area for special use, and this should be a priority. A corner of the workshop can be cleaned and any oil or grease lying on the bench swabbed off. Keep this area clean while clockmaking operations are in progress. It is a good idea to make a false top for the workbench and cover it with baize or a similar material that is soft and will not cause damage to polished metal.

As with all new projects, do not try to run before you can walk. Don’t start by trying to build a complicated mechanism such as a full Westminster Chime, but rather make something simple. A mechanism with a single hand is a good idea; such a piece when well polished can look attractive as well as being fascinating to watch when it is working. Visit museums where clock movements can be studied and note how they work. There is actually nothing very complicated about clocks, and most people should soon grasp the basic principles of construction.

All we are looking for when making a clock is a means of making a spindle with a hand attached to it rotate at a given speed. The spindle needs to be driven by some form of power, usually a very primitive form. A means to regulate that power is also required, in order for it to run at a particular speed. If you are hoping to finish your first efforts in this side of the hobby with a masterpiece that neither loses nor gains more than a second or two a year, then you are probably going to be disappointed. It will be possible to achieve a reasonable degree of accuracy and, more importantly, to discover how to improve that accuracy as a result of what has been learned.

When one purchases a very old clock, the chances of it ever being regulated to keep accurate time are generally very small. In this day and age, we are used to being able to buy very cheap clocks almost anywhere that are remarkably accurate. They are controlled by what amounts to a computer chip, and this is how that accuracy is obtained. These timepieces are what one might describe as soulless—they do not have the fascination of the mechanical device—although it must be admitted, they do their job perfectly. The fact that we cannot get this high degree of accuracy does not mean that our clock will be outrageously inaccurate and, after all, for many years it was quite customary to set a clock to the correct time once every week or so.

Seen at an exhibition at the British Horological Institute were these clocks made basically from Meccano.

Fortunately for those who are beginning, the material that will be used is neither extensive nor expensive when compared to the castings, etc., used for model engineering purposes, so do not be frightened to make a part more than once if something has gone wrong. It is far better than trying to recover something that has not been correctly made in the first place. Unlike building model locomotives or traction engines, where there are expensive castings to be bought, some brass sheet, a few bits and pieces of drill rod, and we are in business.

Although we generally think of brass as the material used for clockmaking, there is no reason why other materials should not be used. The photograph shows a wheel for a clock made from plexiglass (Perspex).

We all tend to think of clocks being made from brass and steel, but other materials can be used. There are a number of plans available for the construction of wooden clocks and, while this may not sound like a suitable material, it is surprisingly robust: the Germans have used it for years to make clocks commercially. Nowadays plastic can be a useful material. It is easy to work with, it is durable, and a clock made of a transparent plastic can be a fascinating thing to see. Also available are plans for clocks made from paper and cardstock (card). They appear to work very well and last for a long time.

Tools

Most of the tools likely to be needed will be found in the workshop of the average model engineer. Needle files, hacksaw, lathe, some small drills, and taps are the basic items that are wanted. In addition, a small five-sided broach is possibly the only essential item that might not already be part of the workshop equipment. There are additional tools, of course, but they are not absolutely essential. Wheel and pinion cutters could be very useful, but it is quite possible to go without them. There are many people making very fine clocks who have never bought such a cutter in their life. A depthing tool (see Chapter 6 for further information) is useful for laying out the wheels, but once more, far from essential; there are several ways of doing the job without such an item and, like cutters, they are easily improvised. Another useful item is known as a Jacot tool; it is used to obtain a high polish on pivots and as an aid to making them. It is quite possible to work without one and, if it should be thought to be an absolutely vital piece of equipment, it is very easily made.

One tool that will be essential is the five-sided broach as seen here. They are available in a variety of sizes and can be obtained in complete sets. The type shown is for cutting pivot holes; another type is available for smoothing them.

The Lathe

Watchmakers’ lathes are expensive to buy and are of little use for purposes other than watchmaking; in fact, they are of doubtful value when it comes to making clocks. Generally speaking, the type of lathe found in the average model engineer’s workshop is quite suitable. The most popular of all these are probably the mini-lathes, which have a swing of 7" in diameter. Thousands of good clocks have been made using them and other lathes of a similar size and specification. The miniature-type lathes with center heights of about half that have the advantage of being cheap and, because they are small, obviously less space is required. Most are available with a bolt-on mill/drill attachment that makes them ideal for cutting the teeth on wheels. It is not possible to give advice on the best lathe for a newcomer to purchase—it all depends on a particular preference and one’s budget. In addition, many of the foreign lathes that are sold are only available for a limited period of time before the specification is changed. Anyone wanting to purchase a lathe would do well to visit one of the model-engineering exhibitions held throughout the country, where it will be possible to browse through a large number of machines of different makes and types to find which might be the most suitable.

Generally speaking, the tools needed for clockmaking will differ little from those used by a model engineer, although one or two extra items may be required. The photograph shows a piercing saw, which is useful for many purposes, but in particular for crossing-out wheels.

A small hand clamp like this one can easily be made very quickly and is invaluable for holding small parts while working on them.

Some of the methods used by clockmakers are likely to make an experienced engineer wince. For example, while the engineer will always try and get as much bearing surface for a spindle as possible, the clockmaker seems to try to do the exact opposite. Holes that are to be used for bearings are drilled smaller than the diameter of the spindle that will fit in them, and then they are reamed with a taper broach until a fit is made. As a result, the spindle is running on the thinnest possible ring of brass. To the engineer the idea sounds frightening, but really it makes complete sense. Although the movement or mechanism is rotating continually, it is hardly going to break any world speed records in so doing. It has no real work to do inasmuch as it is only driving itself, and so the small bearing surface has the advantage that it cuts friction down to a minimum. As a result, it reduces the power needed to run things.

Terminology

This is another thing which engineers may find a little difficult to understand. A shaft or spindle is known as an arbor and the bearing surface at the end is not a shaft or axle but a pivot. Gears become wheels in spite of the very obvious teeth all round them, the making of which is the main part of clockmaking. Although the teeth on the wheels are called teeth, when they are on a pinion they are frequently described as leaves. These gears (wheels) are made of thin section brass, which is ideal for the mechanism that is being constructed. In order to give a good fit on the spindles (arbors), they are fitted on bosses, from now on known as collets. To an engineer, a collet is something that opens and closes to hold tools or material. To a clockmaker, the term includes the length of brass used to support a wheel. And, finally, there is the mechanism itself, which is called a movement. It is all very confusing at first, but we must remember that every trade has its own terminology—just look, for example, at those used by the computer engineer.

Two members of the British Horological Society at work in the workshops. The photograph gives some idea of the type of bench to aim for. A clean surface, a tray for parts, and a good light are the basics, with some small storage stands for the few tools required.

Generally speaking, any lathe will do for clockmaking. The photograph shows the Cowell, which has been specially designed for the purpose.

Help and Assistance

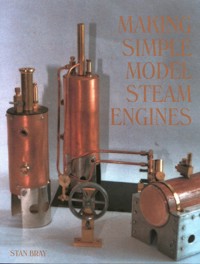

There are a considerable number of plans available for making clocks of various types. Some, such as the designs of John Wilding, are sold in book form, complete with full instructions; they are very highly recommended. Other similar books are available as basic plans, and in some cases complete kits can be purchased. The photograph on the front cover of this book is one of a movement made from just such a kit, by Repton Clocks, and this, too, is an ideal way to learn the basics of clock construction. There are also a number of suppliers of clock parts and books based throughout the country.

The British Horological Society stocks a wide range of books and plans. Here we see a photograph of the library, possibly the most extensive in the world on the subject of watches and clocks.

If we accept all the oddities that are imposed upon us, clocks are fascinating. There are no heavy castings to hump around, the work is nice and clean, and the end result is worthwhile. Even if after reading this book the reader should decide that clockmaking is not for him or her, it is still worthwhile taking an interest in them, their history, and the beauty of the finish on many. This in itself can provide an everlasting interest.

This book deals with simple clockmaking techniques; it is possible to progress further to such things as striking clocks or, perhaps, as seen here, an orrery, which gives the rotation and phases of the moon and planets in relation to the world.

Chapter 1—History

Before starting on constructional details of clockmaking, a word or two on the history of the subject may assist readers in an understanding of timekeeping in general. It is not only the human race that uses timekeeping methods; animals know when it is time to go to sleep or, if nocturnal, when to start searching for their food. Some plants and trees will close down flowers at night and open them when daylight appears. Of course, this has nothing to do with clocks as we have come to know them; they are reacting to light and dark and possibly also to changing seasons. No doubt the human race also started in this fashion, sleeping during darkness and active during the daylight. The clocks in use then were the sun and moon, not necessarily the most reliable sources, as, for various reasons, they are not always visible. Such primitive methods, while not exactly telling the time of day, did give reasonably accurate measurement of the seasons, and so had their uses.

It was not all left entirely to chance. Archaeology and ancient manuscripts tell us that the movement of the heavens has been observed for thousands of years and that this movement has been applied to timekeeping methods. The new moon appears every thirty days and the seasons repeat themselves every twelfth time it appears, which forms the basis of the year as we now record it. The equinoxes were well known and used for religious purposes, and stars and sun were used for early navigation, whether across sea or land.

During and prior to the Stone Age (from about 3.3 million years ago to 8000 BC), it is very doubtful if anything more accurate than this would be required. If the sun was at its highest point, then it was halfway through the day. Humans are never satisfied with basics and we can only speculate when it became desirable to be able to split time into smaller parts and exactly how it was done. It seems highly probable that a primitive sundial would be the first basic form of clock. Put a stick vertically in the ground, and when the shadow cast by that stick is at its shortest, it is midday. Who knows, perhaps it was a tree that first gave someone the idea that the shadow of the sun could be used to give an approximation of time.

Sundials did not remain as sticks in the ground, and we know stone columns were used in early times, metal pillars of varying shapes following them. This is not, however, a book about sundials but about clocks. The sundial subject is so vast that it would take a separate book to discuss it. What we do know is that sundials were in use around 200 BC, and a hundred years or so later a geared mechanical device was produced for navigational purposes at sea, which may or may not have been a primitive form of clock. In 600 BC, the Pope decreed that all religious institutions should have a sundial as a means of regulating the times for prayer, so the human race was really becoming more time conscious.