Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: Books on Demand

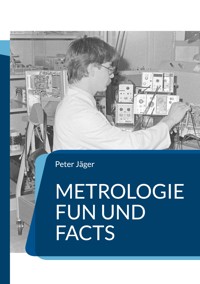

- Kategorie: Wissenschaft und neue Technologien

- Sprache: Englisch

This book is intended to provide concentrated information on the subject of torque wrenches. Torque wrenches have undergone a rapid development from simple tools to precise measuring tools. This is due to advanced mechanization, ever-improving manufacturing methods and optimization processes. While it was still possible to repair a motor vehicle with a set of wrenches in the 1970s, such an "intervention" today would be a blatant safety risk and probably also the technical end of an engine, for example. Torque wrenches have also become indispensable in the medical field. Dental implants, for example, are precisely placed and fastened with the smallest torques. Unfortunately, it can be observed that the landscape of standards and regulations - thought out and developed by experts - is often not, or only slightly, transported to the people who are supposed to implement the normative specifications. This book is intended as an introduction to the subject of torque wrenches, providing the user with basic knowledge and serving as a reference work and list of references and a usefull helper for torque wrench calibration issues.

Sie lesen das E-Book in den Legimi-Apps auf:

Veröffentlichungsjahr: 2023

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

Table of Contents

Foreword

Definitions

Introduction: Metrology everywhere

Physical basics

Torque

Newtonmeter

Screw- or bolted connections

Influencing variables on bolted joints

Bolt classification

Torque and friction

Comparison suit DM / DM and DW

Importance of screw fittings

Torque wrenches – types and styles

Click torque wrenches

Slipper torque wrenches

Mechatronic torque wrenches

Buckling torque wrench

Beam torque wrenches

The Chrysler torque wrench

Electronic torque wrench

Programmable electronic torque wrenches

Reference torque- / transfer wrenches

Torque wrench handling

Torque wrench application

Handling of click torque wrenches

Torque wrench application rules

Torque wrench don’ts and dos

Consequences of improper handling

Normative references

ISO 9001:2015

ISO/IEC 10012:2004-03

ISO 6789 – 1

ISO 6789 – 2

DAkkS-DKD-R 3-7

ISO 6789-2:2017 requirements

Variation due to the reproducibility of the torque tool b

rep

Variation due to geometric effects of the output drive of the torque too b

od

Variation due to geometric effects of the interface between the output drive of the torque tool and the calibration system b

int

Variation due to the variation of the force loading point, b

l

Remark / Evaluation

Calibration

Why calibration?

Definition Calibration:

Accreditation bodies and -laboratories

DAkkS

A2LA

CNAS

Calibration laboratory with accreditation

Metrology basics

Profile of a test-and measuring device – added value

Replacing a torque wrench for cost reasons

Traceability

Documentation

Calibration hierarchy

Measurement uncertainty

Measurement uncertainty - short introduction

Systematic deviations

Random deviations

Uncertainty of measurement or tolerance?

Labeling of test- and measuring equipment

Calibration intervals

Indication of the recalibration time

Start of calibration interval

Pausing use

Calibration interval of torque wrenches

General information on calibrations and calibration intervals

Calibration scheduling

Calibration services requirements

Checklist calibration

Service- or traceable calibration

Calibration results

Post- calibration checks

Calibration certificate

Interval specification in a calibration certificate

Statement of conformity

Decision rule – what’s behind?

Must a torque wrench be compliant?

Room for big mistakes

Insert torque wrench completely!

Insertion parts / accessories!

Cheap / low quality

Ugga Dugga

Impact wrenches / nut runners

Machine capability testing

VDI/VDE 2649:

Bibliography

Foreword

This book is intended to provide concentrated information on the subject of torque wrenches.

Torque wrenches have undergone a rapid development from simple tools to precise measuring tools. This is due to advanced mechanization, ever-improving manufacturing methods and optimization processes. While it was still possible to repair a motor vehicle with a set of wrenches in the 1970s, such an "intervention" today would be a blatant safety risk and probably also the technical end of an engine, for example. Torque wrenches have also become indispensable in the medical field. Dental implants, for example, are precisely placed and fastened with the smallest torques.

Camlog-Dental-Torque wrench 0–30 N cm

© Raimond Spekking / CC BY-SA 4.0 (via Wikimedia Commons), CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=81060121

Together with the general development of measurement technology, various standards and specifications have also developed around torque wrenches, which are compactly shown and explained in this book. It is intended to guide the most important standards and the reference points without the reader having to obtain, read and holistically understand these standards.

The idea for this book came from countless inquiries - by phone, in person, or by email over many years from people who were confronted with the issue and were looking for support.

Unfortunately, it can be observed that the landscape of standards and regulations - thought out and developed by experts - is often not, or only slightly, transported to the people who are supposed to implement the normative specifications. This book is intended as an introduction to the subject of torque wrenches, providing the user with basic knowledge and serving as a reference work and list of references.

Definitions

All definitions are taken from:

BIPM

International vocabulary of metrology – Basic and general concepts and associated terms (VIM)

3rd edition, 2008 version with minor corrections

This vocabulary is the reference for all metrological terms in this book.

Available on www.bipm.org.

BIPM is

The Bureau International des Poids et Measures. It is

the international organization established by the Metre Convention, through which Member States act together on matters related to measurement science and measurement standards

the home of the International System of Units (SI) and the international reference time scale (UTC).

Introduction: Metrology everywhere

Assurance of product quality is of increasing importance for every company, especially with regard to the need to maintain or consolidate its economic position on the market. Nowadays, high quality requirements for a product necessarily mean that an appropriate quality management system must be in place (keyword "product liability").

These findings are not new -modern technology and the possibilities both in mechanical manufacturing and in electronic measurement data acquisition and utilization have replaced earlier manufacturing methods. There is no longer a "fit" or a "thumb value".

The compulsion to act economically and modern manufacturing technology lead to the processualization of work.

In terms of core factors, business processes and technical or manufacturing processes hardly differ. In order to reduce vagueness, it should be noted that the further considerations and explanations refer exclusively to technical processes in distinction to services.

Physical basics

Torque

Torque (also moment of force, from Latin momentum motive force) describes the rotational effect of a force on a body.

Torque is a physical quantity in classical mechanics and corresponds to the force for rectilinear movements - but for rotational movements. A torque can accelerate the rotation of a body and bend (bending moment) or twist (torsion moment) the body.

In drive shafts, torque, together with speed, determines the transmitted power - a crucial quantity for evaluating the performance of a motor vehicle, for example.

The internationally used unit of measurement for torque is the newton meter.

If a force acts at right angles on a lever arm, the amount M of the torque is obtained by multiplying the force F by the length of the lever:

What is simply expressed by this formula can only be implemented in practice by taking numerous influences into account.

In practice - e.g. when using a torque wrench - the force does not usually act at right angles on the lever arm. In theoretical terms, the force application can be drawn into a force parallelogram. This is referred to as a pair of forces. Conversely, in statics, each torque can also be described by a force pair

Von Pietz - Eigenes Werk, CC BY-SA 3.0,https://commons.wikimedia.org/w/index.php?curid=10621446

Newtonmeter

The Newton meter (Newton x meter) is

the unit for the vectorial quantity torque and

for the scalar quantities (mechanical) energy and work.

In e.g. Word, "N ∙ m" can be entered by typing "N then alt + 0183 then m".

Name of unit

Newtonmeter

Symbol

Physical

dimension

Torque, mechanical work

Formu

la

symbol

Dimension

System

International

sytem of units (SI)

SI

unit

Derived from

Newton, Meter

Screw- or bolted connections

A screw connection is a detachable connection of two or more parts by one or more screws. Bolted joints are the only commercially used joining technique that can be undone. All other techniques - such as welding, soldering, riveting, gluing and others cannot be undone without destruction without effort.

A bolted connection can be mentally reproduced by imagining the components between the bolt head and the nut as a tension spring. All the components that are in between - washers, sheet metal, but also loss components such as dirt, rust, unclean thread run - should be pulled together / held together by this spring.

However, it is precisely these components that act against the spring and can be assumed to be a compression spring from the point of view of these components.

By tightening the screw connection, the screw is stretched over the range of the components.

This force is referred to as the preload force. Accordingly, preload force is generated by the internal tension of the components.

With

F :

Preload force in N (in the elastic range)

l :

Change of length in mm

E :

Modulus of elasticity ( Steel ~ 210.000 N/mm

2

)

As :

Stress cross section in mm

2

VDI 2230 sheet 1 therefore prescribes: "Bolts shall be sized to withstand the operating forces encountered and to perform the function of the joint formed."

The yield strength - also called the yield point - indicates how far a bolt can be stretched: A cheap spring will serve as an example to illustrate the processes:

If this is stretched in the intended operating range, it returns to its original shape after the stretching stops. If this spring is stretched too far, it loses its original shape; the coiled wire stretches or breaks off. Steel behaves in a very similar way.

The yield strength is reached from the point where the metal still forms back to its original shape after being stretched. If this is no longer the case, the limit has been exceeded and the screw may no longer be used..

Influencing variables on bolted joints

A bolted connection has a wide variety of influences that must be taken into account for a strong connection:

Occurring operating forces

Axial forces

Transverse forces

Bending moments

Torsional forces

Load change

Significant influencing variables are also introduced (around) the screw itself:

Strength class

Friction

The setting behavior

The tightening method

Size

Geometry of the screw.

The tightening of a bolted joint is a complex process: Tightening a bolt with the nominal torque is not yet a guarantee for correct bolting over a time span that is as unlimited as possible. The force that holds the two parts together is the preload force within the joint. The preload force stretches the bolt and is the force that prevents the connection from loosening.

The actual target value of preload force cannot be measured during assembly at present! This is only possible in individual cases (laboratory, test).

Bolt classification

Screws are subject to classification.

One finds

1. digit:

This digit represents 1/100 of the minimum tensile strength.

2nd digit:

This digit represents the ratio of the material yield strength to the tensile strength.

Example:

A bolt is marked 8.8

1st digit:

1/100 of the minimum tensile strength:

Torque and friction

There are always frictional influences during the bolting process. These are unavoidable, but must be recognized and controllable.

Reasons for friction (among others)

Production tolerances (surface, geometry)

Roughness and foreign particles (e.g. rust)

Lubrication condition: dry, oiled or greased

Material pairing and surface condition

Molecular adhesion and temperature influence

Coating

Comparison suit DM / DM and DW

Tightening with torque only:

+ Easy handling

+ Wide range of torque wrenches

- Strong frictional influence

- Large spread of preload force.

Tightening with torque and angle of rotation:

+ Higher preload force

+ Risk of bolt breakage minimized

- Hardly any frictional influence