28,49 €

Mehr erfahren.

- Herausgeber: Crowood

- Kategorie: Lebensstil

- Sprache: Englisch

- Veröffentlichungsjahr: 2014

A quarter of a century ago, the Land Rover Discovery defined at a stroke how traditional 4 x 4 all-terrain ability could co-exist with family-estate practicality at an affordable price. Since 1989, the Discovery has gone through several iterations, but its essential qualities have remained unchanged. Practical, capable, and above all completely distinctive - the stepped roof seemed odd at first but now defines the Discovery shape - the Discovery has gone on to become one of Land Rover's best-loved products. Land Rover Discovery - 25 Years of the Family 4 x 4 looks in detail at the four generations of Discovery, including full specification details and production histories. Topics covered include the design and development of the original Discovery in the late 1980s, and the move into North America; the new 300Tdi engine and R380 gearbox of 1994, and the BMW takeover; Series II models of 1998-2004, and Land Rover's move from BMW to Ford; Discovery 3/'LR3' - 2004-2009, and the new TDV6 engine, developed by Jaguar; Discovery 4/'LR4' - the all-purpose family luxury car; special editions and derivatives of all four generations of Discovery, including Discoverys for the emergency services and the Camel Trophy and G4 Challenge competition vehicles. Superbly illustrated with 351 colour photographs.

Das E-Book können Sie in Legimi-Apps oder einer beliebigen App lesen, die das folgende Format unterstützen:

Ähnliche

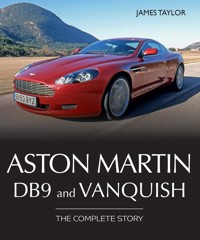

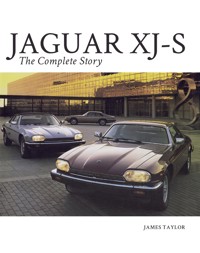

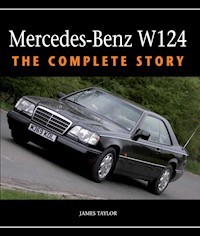

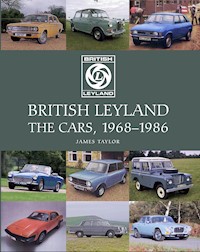

OTHER TITLES IN THE CROWOOD AUTOCLASSICS SERIES

AC COBRA Brian Laban

ALFA ROMEO 916 GTV AND SPIDER Robert Foskett

ALFA ROMEO SPIDER John Tipler

ASTON MARTIN DB4, DB5 & DB6 Jonathan Wood

ASTON MARTIN DB7 Andrew Noakes

ASTON MARTIN V8 William Presland

AUDI QUATTRO Laurence Meredith

AUSTIN HEALEY Graham Robson

BMW 3 SERIES James Taylor

BMW 5 SERIES James Taylor

CITROËN DS SERIES John Pressnell

FORD ESCORT RS Graham Robson

JAGUAR E-TYPE Jonathan Wood

JAGUAR XJ-S Graham Robson

JAGUAR XK8 Graham Robson

JENSEN INTERCEPTOR John Tipler

JOWETT JAVELIN AND JUPITER Geoff McAuley & Edmund Nankivell

LAMBORGHINI COUNTACH Peter Dron

LAND ROVER DEFENDER, 90 AND 110 RANGE James Taylor

LOTUS & CATERHAM SEVEN John Tipler

LOTUS ELAN Matthew Vale

LOTUS ELISE John Tipler

MGA David G. Styles

MGB Brian Laban

MGF AND TF David Knowles

MAZDA MX-5 Antony Ingram

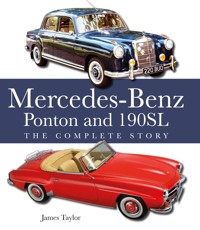

MERCEDES-BENZ CARS OF THE 1990S James Taylor

MERCEDES-BENZ ‘FINTAIL’ MODELS Brian Long

MERCEDES SL SERIES Andrew Noakes

MERCEDES W113 Myles Kornblatt

MORGAN 4/4 Michael Palmer

MORGAN THREE-WHEELER Peter Miller

ROVER P5 & P5B James Taylor

SAAB 99 & 900 Lance Cole

SUBARU IMPREZA WRX AND WRX STI James Taylor

SUNBEAM ALPINE AND TIGER Graham Robson

TRIUMPH SPITFIRE & GT6 James Taylor

TRIUMPH TR7 David Knowles

VOLKSWAGEN GOLF GTI James Richardson

VOLVO P1800 David G. Styles

LAND ROVER DISCOVERY

25 Years of the Family 4 × 4

James Taylor

THE CROWOOD PRESS

First published in 2014 by The Crowood Press Ltd Ramsbury, Marlborough Wiltshire SN8 2HR

www.crowood.com

This e-book first published in 2014

© James Taylor 2014

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage and retrieval system, without permission in writing from the publishers.

British Library Cataloguing-in-Publication Data A catalogue record for this book is available from the British Library.

ISBN: 978 1 84797 690 1

CONTENTS

Introduction and Acknowledgements

CHAPTER 1CONCEPT, DESIGN AND DEVELOPMENT

CHAPTER 2THE ORIGINAL DISCOVERY, 1990–94

CHAPTER 3NEW HORIZONS: MOVING UPMARKET AND INTO NORTH AMERICA

CHAPTER 4SPECIAL EDITIONS: FIRST-GENERATION DISCOVERYS

CHAPTER 5SPECIAL DERIVATIVES: VARIANTS OF THE FIRST-GENERATION DISCOVERY

CHAPTER 6DESIGNING THE SERIES II

CHAPTER 7THE SERIES II MODELS, 1998–2004

CHAPTER 8SPECIAL DERIVATIVES AND SPECIAL EDITIONS: BUILDING ON THE SERIES II DISCOVERYS

CHAPTER 9A FRESH APPROACH

CHAPTER 10DISCOVERY 3

CHAPTER 11DISCOVERY 4

CHAPTER 12SPECIAL VERSIONS OF THE DISCOVERY 3 AND DISCOVERY 4

Appendix: Building Discoverys

Index

INTRODUCTION AND ACKNOWLEDGEMENTS

The Discovery was an exceptionally important vehicle in the history of the Land Rover marque. Before its introduction in 1989 there were utility Land Rovers and increasingly luxurious and expensive Range Rovers, but nothing that really appealed to the buyer of everyday family transport. The Discovery filled that gap, and in doing so it turned Land Rover from a niche-market manufacturer into an important player in the mainstream car market.

Although the ‘family’ Land Rover inevitably also became the butt of both humour and environmentalist protest when it became a favourite middle-class school-run car, it survived with flying colours. As Oscar Wilde wrote, ‘there is only one thing in the world worse than being talked about, and that is not being talked about’. Land Rover built cleverly on the success of the first-generation model, and now, a quarter of a century after it first went on sale, Discovery has become a byword for a practical, prestigious and extraordinarily capable all-rounder.

Yet the first vehicles were cobbled together in record time on the platform of the original Range Rover. Land Rover knew the product it wanted, but needed it quickly and affordably, and was able to achieve something that fell just short of a miracle. I first drove one of those early Discoverys (G462 WAC, as it happens) at a media off-road ride-and-drive event at Eastnor Castle in November 1989 and was very impressed. The garish side graphics were not to my taste, but most of the rest of the vehicle certainly was.

The Discovery quickly grew up. Buyers made clear that they wanted more features and that they were prepared to pay for them. Within five years leather upholstery and other luxuries were available in top models. Quality was the next major stride forward as the Series II models came on-stream in 1998, and I have never regretted my purchase of one of those in 2001, a vehicle that today is still everyday family transport, business car and recreational off-roader. With the third-generation model in 2004, Land Rover surpassed the levels it had attained with earlier Range Rovers – and today there are still many customers who see the Discovery as preferable to Land Rover’s flagship model because of its enormous practicality.

I have been mentally putting together the story of the Discovery ever since its 1989 appearance and have written extensively about it over the years in various magazines, such as Land Rover Owner, Land Rover Enthusiast (which I edited from 2000–2010) and Land Rover Monthly. My own interest has been fuelled by other people’s researches, too, and I am pleased to say a very big ‘thank you’ to those who have shared the research with me. Many more people have helped out than I have room to list here, but a huge amount of information, encouragement and enthusiasm has come from the people at Land Rover who actually played a part in the Discovery story. So, in alphabetical order to avoid favouritism, here they are: Tim Ackerley, John Bilton, Keith Bird, Roger Crathorne, Mike Donovan, Dave Evans, Stuart Frith, Mike Gould, John Hall, Steve Haywood, Grant Horne, Bill Morris, Dave Saddington, Mike Sampson, Glenn Smith, George Thomson, Geoff Upex and Les Wilkins.

Photographs have come from a variety of sources, but very many have come from Land Rover itself and from those who have worked with the company. Some are my own; others have come from enthusiasts who were lucky enough to catch an interesting vehicle at the right time. Again, my sincere thanks go to everybody who has made a contribution.

James Taylor Oxfordshire, February 2014

CHAPTER ONE

CONCEPT, DESIGN AND DEVELOPMENT

The idea of a 4 × 4 as an everyday family vehicle barely existed at Land Rover’s Solihull home as the marque entered the 1980s. At that stage the company had just two model-ranges. One was the Land Rover itself, the latest evolution of the workhorse model that had entered production in 1948 and was still recognizably the same vehicle. By then in Series III guise, it also offered Station Wagon variants as passenger-carriers, but these were most certainly not mainstream family vehicles. Rugged, spartan, noisy and slow, they were very obviously derived from what had always been a specialist commercial vehicle.

The company’s second model range was the Range Rover. Introduced in 1970, this had originally been designed as a Land Rover that was more suitable for road use, adding performance and higher comfort levels to the existing Land Rover formula. Although it was considerably more expensive than the Land Rover, during the 1970s it attracted buyers who saw its potential as an everyday vehicle. Land Rover was held back, however, by a lack of investment. As one of British Leyland’s many marques, it was unable to invest its own profits because these went into the corporate British Leyland coffers and were redistributed to parts of the group that needed them most, notably the loss-making Austin-Morris cars division. So the Range Rover could be neither developed significantly nor built in greater numbers to meet burgeoning demand.

All that began to change in 1978. British Leyland had run out of money at the end of 1974 and turned to the Government for help. Nationalization followed swiftly in order to protect jobs and overseas trade, but the Government also commissioned a thorough report into the car company’s affairs. The Ryder Report’s recommendations were largely overturned in the mid-1970s, but one that remained intact was a proposal to make Land Rover a separate business unit. Land Rover Ltd was established in 1978, separating the 4 × 4 vehicles from the Rover car marque that had sired them. Major investment followed and by the start of the 1980s it looked as if Land Rover had a secure future.

Yet just as the company was gearing up to build more and better vehicles to meet demand, its major markets began to collapse. The major loss was in Africa, a traditional Land Rover stronghold that went to the Japanese. One cause was that the British Government changed the overseas aid arrangements that had previously encouraged African governments to buy British. Another was that the Japanese manufacturers, expanding their exports rapidly during the 1970s, had quickly spotted that Land Rover was unable to meet demand from Africa and had developed cheaper 4 × 4 vehicles for that market. Things went from bad to worse, and 1983 and 1984 were the company’s worst-ever trading years, with a combined loss of around £40 million.

The Japanese makers had also begun to exploit the potential of a new market, again at Land Rover’s expense. That new market had been opened up during the 1970s by the Range Rover, which had become an aspirational alternative to the conventional estate car. Its purchase price and running costs put it out of reach for most family buyers and the Japanese makers moved smartly into the market vacuum it had created, designing cheaper 4 × 4 estate models that were deliberately aimed at family buyers.

During 1981 Isuzu introduced the Trooper and Mitsubishi the Pajero, called the Shogun in Britain. These models found a ready market outside Japan, and especially in Europe. There were four-door family variants and short-wheelbase two-door derivatives aimed at those with an outdoor lifestyle but who did not need the extra seats to carry children. These Japanese 4 × 4s really started the four-wheel-drive boom in the developing countries, selling to a market where Land Rover was unable to compete. It was neither the traditional 4 × 4 workhorse market nor the expensive luxury 4 × 4 market, but somewhere in between. In later years, Land Rover’s research would categorize it as the Personal Transport Sector of the 4 × 4 market.

By the end of 1982, Land Rover was in trouble. Sales had collapsed in its largest overseas markets, and there was no doubt that it would take several millions of pounds and a good number of years even to regain its competitive edge against the latest Japanese 4 × 4 utilities. Indeed thirty years later, as this book was being written, it had still not done so. Equally, its credibility as a major player in the 4 × 4 market was being threatened by its failure to compete in the new family 4 × 4 sector opened up by the Trooper and the Pajero. This was a crisis, and when new Managing Director Tony Gilroy arrived from British Leyland’s Freight Rover van division in January 1983, it was clear what his priority must be.

Gilroy initiated a ground-up review of Land Rover’s products and markets. His predecessor as Managing Director, Mike Hodgkinson, had already sketched out plans for streamlining the manufacturing operation by closing satellite factories and centralizing production at the company’s Solihull factory, and Gilroy accelerated this process. Even before the full review had been completed, however, certain things had become clear. It would be far too costly and risky to try to regain Land Rover’s lost markets for utility vehicles in developing countries. Instead, the company should focus on selling vehicles in the developed countries, and should do so by improving its Range Rover luxury product. The major targets would be Europe and the USA.

By the time the report was completed early in 1986, one other recommendation was quite clear. This was that Land Rover should develop a third product line to compete with the Japanese family 4 × 4s, to sell in volumes larger than either the Land Rover utilities or the Range Rover, and to generate the profits that would enable the company to develop further new products and to keep ahead of its rivals. The major demand for this new product was expected to come from Europe and the other developed countries. From this firm recommendation grew the vehicle that would be launched as the Land Rover Discovery just over three years later.

With the requirement for a new product in place, the next problem was to define and develop it. Land Rover’s recent losses meant that the company was in no position to finance a major new product, and yet the company needed the new model quickly in order to finance its very survival. So the idea was born that the third model range should be based on existing hardware in order to minimize both cost and development time.

First thoughts focused on developing a more sophisticated Land Rover, but the problem was that the Ninety chassis was too small and the One Ten too large for the family 4 × 4 market. Midway between them was the 100-inch wheelbase of the Range Rover chassis, but at first there was considerable resistance to the idea of using this.

John Bilton, then working on the powertrain side of Land Rover’s Product Planning Department, remembers that many Solihull people thought the Range Rover chassis would be too costly, but this group was eventually won over when it became clear that manufacturing costs would be reduced drastically through increased production volumes. Others were afraid that Range Rover sales would suffer if the model’s chassis were used for a cheaper vehicle. This group preferred the idea of basing the new mid-range model on the chassis of the proposed Land Rover replacement, which was known as the Inca project. Inca was half of a long-term plan to build future Land Rovers and Range Rovers on a common chassis, and the Range Rover derivative was known as Ibex. This project never came to fruition.

The document that became known as the Gilroy Review was already circulating in draft form before it was seen by Tony Gilroy himself, and there were those at Land Rover who enthusiastically embraced the idea of a new vehicle based on the Range Rover chassis. Among them was Tim Ackerley, the company’s Marketing Director. He formally put the idea of a Range Rover-based vehicle to the Product Policy Committee as early as 6 December 1985 in the guise of an Interim Model Strategy. The idea was accepted for further consideration.

Tony Gilroy, however, was not a man to be rushed. In the early months of 1986 he read through the final version of the review he had commissioned and considered the options. There was no doubt about the wisdom of going for a third model to tackle the family 4 × 4 market, but Gilroy wanted to be absolutely certain about how best to do it. So he established a six-man team called the Swift Group to make recommendations. At this stage, the project was given the code name of Jay, the Range Rover-based idea becoming Jay One and the Inca-based project Jay Two.

The Swift Group started work in May 1986 and took thirteen weeks to prepare its report. Meanwhile, Tim Ackerley had managed to win support for his Interim Model Strategy from several fellow Directors at Land Rover: Bill Morris in Engineering, Bob Dover in Manufacturing and Alan Edis in Product Planning. Working without official sanction, these individuals had developed the concept to quite an advanced stage even before the Swift Group announced that it favoured the Range Rover-derived Jay One proposal for the new vehicle. As a result, a full-size clay model of Jay came together very quickly and was ready for viewing by the Rover Group Main Board as early as September 1986. (This was the equivalent of the earlier British Leyland Main Board, which became the Rover Group Board when the company was renamed over the summer of 1986.) The decision to proceed was not immediate, because the Jay proposal was competing for funds with a proposed new MG sports car, but in due course the Board decided in favour of the Land Rover proposal and the MG project was abandoned.

The starting-point of the Jay project was the existing Range Rover chassis, seen here in its early 1970s form with the original four-speed gearbox.

A key factor in securing the Rover Board’s backing was that Land Rover believed it could bring the new model to market very quickly by adopting some innovative working methods. The industry norm at the time was to take five years, but Land Rover needed the Jay vehicle by autumn 1989, less than three years away, in order to meet its own business targets. The Swift Group had adopted a multidisciplinary approach in order to deliver its report very rapidly, and Land Rover planned a similar approach for its engineering programme.

This approach was later described as ‘simultaneous engineering’. The traditional motor industry approach was for one specialist group, such as chassis designers, to finish its job before passing the project to the next group, such as body engineers. Using simultaneous engineering, all the specialist groups started work at the same time, keeping one another constantly informed of progress. It dramatically shortened the time needed for the design stages of the vehicle, and reduced time-wasting conflicts between different design areas. Development and testing, meanwhile, went ahead in parallel. Nevertheless, the three-year target could not have been met if Land Rover had not started with some major items of hardware already in production, most notably the Range Rover chassis and one of the engines that the new model would use.

Bob Dover, then Director of Manufacturing, put his weight behind the Jay project. Just over ten years after the Discovery’s introduction, he would become Land Rover’s Chairman and CEO.

The Jay Project Team was formally established at the end of 1986 under Mike Donovan, who had been one of the Product Planners on the Swift Group. It was a big job, with a more wide-ranging set of demands than had been the case in previous Land Rover engineering projects and a new set of working methods to master as well. Mike found himself managing a team of fifty people at the project’s most intense period. In addition to designers and engineers, the team included marketing specialists who ran a continuous programme of further surveys over the next two and a half years to make sure that the market foreseen in 1986 did not change. Telephone interviews in the UK, Europe, Indonesia, Australia and the USA were followed by concentrated market research in Europe and the UK and by customer clinics in these two market areas.

Looking the Part

The biggest problem that came with using the Range Rover chassis lay in differentiating the new model from the older, more expensive one. The burden here fell very largely onto what was then called the Styling Department at Land Rover, but would soon be renamed the Design Studio.

The Land Rover styling teams were led by Dave Evans, seen here with an early production Discovery.

At the end of 1985 the department was based at Drayton Road. The Chief Designer was Dave Evans, who had recently come in from Chrysler UK, and working to him were four designers: George Thomson, Mehmet Ozoturk, Alan Sheppard and Mike Sampson. Later there would be seven of them: George Thomson would become Manager for Exteriors with Mike Sampson and Richard Bartlam working to him, while Alan Mobberley would become Manager for Interiors with Mehmet Ozoturk, Alan Sheppard and Mike Brogan as his team.

From the start, the Jay vehicle was to be offered with ‘occasional’ rear seats to give a total capacity of seven, as this was what the family market expected. The first sketches were made at the start of 1986. As Mike Sampson recalled in 2008, ‘The vehicle was to be a Land Rover, so the only reference I had was the Station Wagon roofline – so I tried that.’ This provided a raised rear roof to give headroom to the occupants of the rearmost seats, which were directly above the fuel tank of the Range Rover chassis; as a result the floor could not be lowered in this area.

Mike’s first sketch in January also picked up on three other Land Rover features: the white-painted roof panel, the Alpine lights and the spare wheel carried on the tail door. Interestingly, he envisaged the new vehicle as a four-door type from the beginning, even though it was always part of the plan to build a two-door body as well to widen its appeal and interest younger buyers without children.

Various drawings over the first few months of 1986 followed the lead set by this initial sketch, and over the summer of that year a first full-size mock-up was built, using modelling clay to simulate the visible surfaces. ‘That first clay was built at Drayton Road and it was on a Range Rover body frame and chassis,’ remembers Mike Sampson. ‘We even used the screen and doors with glazing to give us an early look at a see-through model. It could also be steered but not driven as there was no power train.’ There was, though, a tow hitch – clearly something that was seen as important for future customers of the new vehicle.

As is common with design models, that first clay had one design on the left-hand side and an alternative on the right. George Thomson’s design was on the left and Mike’s on the right: it is interesting that neither yet had the outside spare wheel that would become part of the production design. Both had the Station Wagon-style tapered roof and Mike’s version even incorporated Range Rover rear light units.

Mike Sampson’s first exploratory sketch, dated 21 January 1986. It shows the original idea for a raised roof with Land Rover-style Alpine lights and exposed spare wheel.

Dated 14 April 1986, this Mike Sampson sketch shows a simple raised roofline, with Alpine lights at the rear that blend with a glass roof section.

The clay was refined over the summer of 1986, taking on a tail-mounted spare wheel to reinforce the visual link with Land Rover Station Wagons and create more interior space. It also gained full glazing at the rear, where the first version had only black panels to simulate glass. But it looked too much like the high-roof version of the Mitsubishi Pajero and it did not yet have the character that the Project Jay team wanted.

This 19 April 1986 sketch by Mike Sampson proposes a sloping front to the raised roof, with large Alpine lights derived from the Land Rover type.

This proposal was getting close to the finished article, but the roof has no Alpine lights, the front end needs further work, and exposed front door hinges are still in the plan. However, as a way of disguising the Jay vehicle’s Range Rover origins, it is very successful.

Dated 5 November 1986, this Mike Sampson sketch clearly shows the way the design was progressing, with roof bars to smooth the side profile.

Early proposals for related three-door and five-door designs. The influence of the Mitsubishi Pajero and Isuzu Trooper is very strong.

Dated April 1986, this sketch for the new vehicle came from Richard Bartlam.

This early theme sketch came from Mike Brogan.

This was probably the earliest full-size model, constructed around a Range Rover chassis and bodyshell in 1986. Each side had a different design proposal. The bottom picture shows a slightly later iteration of the model, with clear glass – and a tow hitch.

Then someone on the team, either George Thomson or Richard Bartlam, suggested they should try a stepped roofline instead of the tapered Station Wagon type. ‘The idea was that the roof was only raised in the area that it needed to be, above the rear occupants,’ says Mike Sampson. One of the more radical stepped-roof proposals was tried out on the full-size clay, replacing the George Thomson proposal on the left-hand side. It was in this guise that the clay was shown to the Rover Board during September 1986.

Even though the Board approved the funding for Project Jay to progress to production at the end of the year, there was little doubt that the stepped-roof design tried on the full-size clay was too radical. It would certainly have given the Jay vehicle a distinctive appearance, but it might have scared off some of the family buyers that Land Rover wanted to capture with the new model. So the design team began to look at ways of toning it down without losing its essential character.

Sketches reflecting this line of thinking began to appear in November 1986, and by the end of that month the characteristic outline of the eventual production vehicle had evolved. Mike Sampson believes that it was Richard Bartlam who had ‘the greatest influence on the external appearance of the Discovery’, and one of his sketches from November shows what was unmistakeably the Discovery that would be announced in 1989. It even incorporates the bonnet design, a particular problem because it had to be very different from that used on the Range Rover. Although further detail refinement would continue into 1988, the basic shape of the production Discovery was signed off in February 1987, more than two years before the model went on sale.

Even so, several things changed in the final run-up to production. One was the arrival of side decals, which had been pioneered on some of the Japanese family 4 × 4s and were thought at the time to offer a younger image and another way of differentiating the Jay vehicle from its Range Rover parent. Cost affected other areas. A decision to use the rear light units from the Austin Maestro van had already affected the shape of the Jay vehicle, which by this stage had chamfered rear body corners to accommodate them. It was probably in early 1988 that the planned alloy wheels were thrown out in favour of a much cheaper, and surprisingly attractive, styled steel design. The headlights changed during this period, too. Somebody realized that the rectangular headlamps already in production for the Freight Rover van would fit into the available space, and so the design team adjusted the front end of the Jay design to suit. Sadly, the van lights never would be powerful enough for their new role, and were a weakness of the original Discovery design.

Nearly there: this is an April 1986 proposal from George Thomson featuring the idea of a stepped roof with roof bars, which was carried through to production.

Reality check at Drayton Road in 1986: the full-size buck was positioned between the existing production Land Rover Ninety and the Range Rover to see if it looked like a proper Land Rover product.

Here is ample proof of Project Jay’s Range Rover origins. This interior buck was based on an engineless Range Rover chassis with a Range Rover bodyshell and doors. The raised rear roofline is simulated by a hoop, and a rudimentary rear access step has been added. An early iteration of the Jay dashboard and instrument panel is just visible inside the buck.

Nearly there. This full-size buck dates from late 1987 or early 1988, and shows the Discovery as the designers wanted it. Wheels and headlights would both be changed before production, on cost grounds. The number plate is an interesting concoction: the J is for Jay, 100 for the 100-inch wheelbase, and ADO was always used on models from the old Austin Drawing Office.

The Inside Story

The interior’s design was going to be critical to the new model’s family appeal. In addition to having the option of seven seats to accommodate larger families, the interior had to be practical and flexible, with as much room for oddments stowage as could be achieved.

Recognizing that the interior design needed to incorporate a lot of new thinking, Dave Evans decided to get ideas from two outside consultancies as well as from his own styling team. From the automotive world he chose IAD of Worthing, and from the world of consumer design he chose Conran Design, which was closely associated with the Habitat furniture stores. The brief given to all three groups of designers was to create a unique interior that was different from both traditional 4 × 4 and car designs, but also incorporated 4 × 4 design cues and car levels of comfort.

Some of the ideas that the Land Rover team under Alan Mobberley put forward were as radical in their own way as the exterior ideas that had come from George Thomson’s team. But by March 1987 – the month after the exterior design had been signed off – the proposal put forward by Conran had become a clear favourite. Famously, this had been constructed in a Range Rover body shell that had been craned into the Conran studios in London through an upstairs window.

The key features of the Conran interior were its light blue colour, which made the interior feel more airy and spacious, and its use of textures, which were achieved particularly by means of pips moulded into surfaces such as the dashboard and the driver’s controls. However, it had not been prepared by car people, and so needed some reworking to suit safety, homologation, production and engineering requirements.

The ‘pips’ were reversed to become golf-ball dimples, an idea that came from keen golfers George Thomson and Alan Mobberley. Thomson was of course the man in charge of exteriors rather than interiors but, as Mike Sampson remembers, ‘The demarcation between interior and exterior was not rigid; everyone mucked in where the need was greatest.’ The inward-facing occasional rear seats for the seven-seater versions also came from the Land Rover team, and were largely the work of Mike Brogan. So although publicity at the Discovery’s launch in November 1989 made a lot of the Conran Design connection, the production interior actually owed much more to Dave Evans’s Land Rover design team than the company acknowledged.

Perhaps most important was that the interior design made maximum use of the space inside the vehicle created by the raised roof. The roof above the front seats was actually slightly higher than its Range Rover equivalent, so the designers fitted map stowage pockets above the sun visors. They added stowage nets to the slope of the stepped roof, where rear seat passengers could use them. They designed door trims with deep bins and ensured that the dashboard was flat and useable for oddments stowage. As the two extra rear seats were to be optional, they designed deep stowage bins to fit in their place when the seats were not specified. And they enhanced the light and airy feel of the interior, which resulted from the Alpine lights, by designing not one but a pair of optional glass sunroofs.

These two interior proposals originated with outside design agencies, and both are clearly marked ‘Range Rover’; Land Rover had not revealed that they were working on an all-new model. Though rather fussy and complicated, they suggested some themes that carried through to the production design.

The dashboard comes together in an interior buck, almost certainly based on a Range Rover bodyshell.

This late interior buck for the three-door model has what became the production design. The folding rear seat and its fixing channel are modelled on the left, but the right-hand side shows the alternative style with an oddments bin, as would be used on five-seater models.

Some of the elements of the interior trim had been established by the time of this picture; others had yet to evolve further.

This early dashboard model has the idea of the switches around the periphery of the instrument panel, but lacks the functional design expected of a Land Rover.

The new vehicle’s interior was finally signed-off for production early in 1988. Once again, it is interesting to see how Land Rover had been unwilling to go too far: although the light blue colour looked good and was expected to appeal strongly to the younger people who would buy the two-door models (‘three-doors’ by the time of the launch, because of the big tail door), a version was worked up in beige that was more likely to appeal to family buyers and was launched when the four-door (‘five-door’) models went on sale during 1990.

Curiously, interior design work did lead to one quirky element of the Discovery’s exterior design. With the spare wheel mounted on the tail door, visibility to the rear was somewhat restricted. The wheel was moved to one side and the tail door window was enlarged on the opposite side to improve visibility to the rear. This created the characteristic asymmetric design that would be associated with the Discovery for the next quarter of a century.

Chassis and Powertrain

There would not be a great deal to do to prepare the Range Rover chassis for its new role. Essentially, the chassis frame and suspension could be used in their entirety, give or take some modifications to bracketry. A decision was also taken at an early stage to delete the Range Rover’s self-levelling suspension. This not only saved costs but would also help to distinguish the new junior model from the more expensive established one.

The choice of powertrains, however, was less straightforward. It was immediately obvious that the new vehicle should be offered with a choice of petrol and diesel engines, the latter because buyers in continental Europe overwhelmingly chose diesel. While the long-serving 3.5-litre V8 would be ideal for the petrol option, at the end of 1985 Land Rover did not have a suitable diesel engine in production.

In fact, Land Rover was in desperate need of new diesel engines. The need had become all the more pressing when the company had reorientated itself towards the European market, where 4 × 4 buyers overwhelmingly chose diesel engines. Its existing 4-cylinder diesel was an elderly design that did not give the road performance buyers wanted, even though it was adequate for use in the commercially orientated Ninety and One Ten models. A plan to develop a diesel version of the V8 in tandem with UK diesel specialists Perkins Engines had been cancelled a year or so earlier, and in order to get a diesel Range Rover into production for spring 1986, Land Rover had been obliged to buy an engine in from VM Motori in Italy. This was an unwelcome compromise: bought-in engines add to manufacturing costs and reduce profits, and it was clear that Land Rover needed an alternative as soon as possible.

The task of developing a forward strategy for diesel engines fell to John Bilton, who was in charge of powertrain work in Alan Edis’s Product Planning department. Scooping up the existing VM plans, John suggested a three-phase strategy. First, the existing four-cylinder diesel, already being enlarged to 2.5 litres with a modern belt-drive replacing the old chain drive to the camshaft, should be turbocharged to improve its road performance. This became Project Falcon. Second, the existing project to deliver a diesel Range Rover with the VM engine, code named Beaver, should go ahead as planned. These two would take care of the short-term needs. For the longer term, the third stage would be further development of the existing 2.5-litre engine. Replacing its cast-iron, indirect-injection cylinder head with a new aluminium-alloy direct-injection design would create an engine that would be suitable for the Ninety, One Ten and also Freight Rover vans. At the same time, the petrol versions of the 2.5-litre engine could be updated to give Land Rover a more modern 4-cylinder petrol engine. These related twin projects gave rise to the codename of Project Gemini.

John Bilton knew that Audi, Fiat and Ford were already working on small-capacity direct-injection diesels. Although much more fuel-efficient than indirect-injection systems, direct-injection types had traditionally been reserved for large slow-revving truck and bus diesels because they were very noisy – unacceptably so for the high-speed diesels needed in smaller passenger vehicles and vans. However, the news that other major manufacturers had begun to take direct injection seriously for smaller-capacity high-speed engines suggested that solutions to the existing problems might be within reach.

Both Alan Edis and Tony Gilroy were fully supportive of the plan to investigate direct injection, and work started on the Gemini project late in 1984. At this stage Land Rover intended that it should embrace three engines: a naturally aspirated diesel, a turbocharged version, and a petrol equivalent of the naturally aspirated engine, using a modified version of the new direct-injection cylinder head with bow-lin-crown pistons. This commonality was expected to save on tooling costs while giving the maximum benefit to the company in terms of new engine options. As the existing 2.5-litre cylinder block would be retained, the older Land Rover four-cylinder engines could also remain in production for as long as they were needed.

John Bilton was the Product Planner behind the Gemini diesel engine, which proved so crucial to the success of Discovery.

John Bilton also made recommendations about the transmissions and other engines used in the original Discovery. He recognized that the cost could be kept down by using the inhouse LT230 transfer gearbox in preference to the bought-in Borg Warner chain-driven transfer box that was earmarked for Range Rover; it would also help to differentiate the two models in the marketplace. As far as petrol engines were concerned, retaining carburettors on the 3.5-litre V8 when the Range Rover had gone to 3.9 litres and fuel injection was another important differentiating factor, and the Discovery V8 lagged behind the Range Rover version for many more years, even though it was gradually upgraded.

While Bill Morris, Director of Engineering, concentrated on delivering the Beaver and Falcon projects, much of the initial feasibility work on Gemini fell to John Bilton. He identified potential component suppliers and carried out preliminary negotiations with them. The Audi development work was being done in conjunction with the established specialists AVL, based at Graz in Austria, and Land Rover discovered that they were working in tandem with Bosch as the component supplier. An approach to both companies secured their agreement to work with Solihull on the Gemini project, while in Britain Lucas-CAV agreed to put up a proposal to meet Land Rover’s requirements. In the event, the British proposal was less promising than the joint proposal from Germany and Austria, so Land Rover went ahead with AVL and Bosch.

Bill Morris now assembled his project team in the Engineering Department. Les Wilkins had already been brought in from Leyland Trucks in June 1984, recruited for his experience of direct-injection engines for large trucks, and had been kicking his heels working on the petrol V8 while waiting for Gemini to get under way. He was now despatched to AVL, where he became Land Rover’s link-man on the project. Back at Solihull, John Barnett and Tony Robinson made up the rest of the team, and work went ahead with all speed. Intercoolers were now accepted as necessary to improve both fuel consumption and performance in turbocharged diesel engines, so one was planned into the project. The Gemini team’s initial design aims were to achieve 100bhp in the turbocharged engine (the Falcon engine would have 85bhp) with a 15 per cent improvement in fuel consumption over the indirect-injection type.

The Falcon engine was announced in October 1986. Its immediate and enthusiastic acceptance made two things clear to Land Rover: the future really did lie with diesel power, if Europe was to be the target, and there would be no need for either the naturally aspirated Gemini diesel or the petrol version of the engine. So the plans for both engines, which had not progressed beyond drawing board and discussion, were abandoned during 1987.

Meanwhile, another important sea change had taken place at Solihull. The Gemini engine had originally been planned as part of a cross-range engine strategy, but after Project Jay was given the go-ahead in mid-1986, it became very closely associated with that. Land Rover now planned to launch Gemini in the Jay vehicle first, which meant that it had to be ready by mid-1989. As a fallback, in case the engine was not ready, they ran a programme to use the VM diesel engine in Jay, and some of the prototype vehicles were built with VM engines.

All this lent an extra sense of purpose to the project. Prototype Gemini diesel engines were already achieving excellent results on emissions work and were delivering performance well in excess of expectations. After Solihull representatives drove the Ninety that AVL were using as a test-bed in Austria, all parties agreed to upgrade the design targets to reflect this exceptional progress. The maximum power requirement was raised from 100bhp to just over 111bhp, and the maximum torque from 180lb ft to 195lb ft. Fuel economy was proving to be outstanding.

Next came a batch of about one hundred production-specification test engines. Bench-testing of up to 1,350 hours per unit had begun by the middle of 1987, and examples were on endurance and high-speed road-proving tests by the end of the year. Land Rover had developed a demanding road-proving test of 50,000 miles at full speed, usually run in southern Italy, and data from the Beaver and Falcon projects, which had already been through this process, provided valuable comparisons during the Gemini tests. By this stage Gemini engines were on test in Range Rovers as well as in Land Rovers, and examples were run in both the UK and Europe, while hot-climate testing went ahead in Arizona and cold-climate testing in Canada. Before entering production, Gemini engines had racked up two million road-test miles.

The real key to the success of the Gemini project was the two-stage injectors, which allowed the rate of injection to be controlled more carefully so that the rate of rise in combustion pressure could be managed and the characteristic diesel ‘knock’ could be reduced. They also had a beneficial effect on fuel economy. The original concept of these injectors was AVL’s, although the concept was slightly modified by Bosch in order to achieve consistent reliability in mass production.

AVL was also responsible for the combustion chamber design of the new direct-injection cylinder head, and this was a further important factor in achieving excellent fuel economy and in reducing combustion noise. For its manufacture, Land Rover invested in the latest CNC (computer-controlled) machining technology, a remarkably flexible resource that could be more readily adapted to meet changes than older machine tools. Gemini proved to be Land Rover’s first major use of CNC, although in fact a pilot scheme had already been running for the manufacture of some components for the V8 petrol engines.

Meanwhile, the original plan to use the block of the existing 2.5-litre diesel engine had gradually become unworkable as Gemini development had progressed. Minor modifications turned into major ones, and in the end the block became quite different, even though it could still be machined on the same transfer lines at Solihull. According to Bill Morris, the Gemini designers got away with this, which was strictly outside the terms of the project and therefore had no budget, by describing them internally as running modifications to the older block. The crankshaft, too, ended up being redesigned for Gemini, although to keep manufacturing costs down, the new and stronger crank was also fitted to the older 2.5-litre diesels when Gemini production began.

By 1988 the engineering work on Gemini had progressed to the certification phase. Careful planning with Bosch had ensured consistency in the fuel injection performance, and emissions test results comfortably met the existing European standards. Nevertheless, by the end of the year there was still one unresolved problem – and this problem was so serious that it very nearly resulted in the cancellation of the Gemini engine as the diesel option for the new Jay vehicle.

The whole 200Tdi programme was nearly scuppered when a problem arose with the skew gear. The original design is on the left; the redesigned item on the right.

Gemini had inherited from the original four-cylinder Land Rover diesel engine a camshaft-driven skew gear on the left-hand side of the block; this transferred the camshaft’s horizontal drive onto a vertical plane, and drove the oil pump and the vacuum pump for the brake servo. This skew gear was exactly the same as that on the production 2.5-litre diesel engine, but it was clear that the extra stresses of the direct-injection Gemini engine were causing it to fail – and that after no more than 30,000 miles.

Working under considerable pressure, Les Wilkins and his assistant Keith Bird discovered where the weaknesses lay and completely redesigned the offending skew gear. The solution was to fit a second bearing above the skew gear, in the form of a ball bearing. This was able to control the alignment of the gear teeth and handle the fluctuations in the end load caused by the excitation from the high-pressure fuel pump transmitted to the camshaft through the timing belt. The new component worked very well, but there was no time to put it through a full test cycle before production of Discoverys for the dealers’ launch stock was due to begin. Somebody at Land Rover took a brave decision, and pilot production of the new Gemini diesel engine began in the spring.

The Gemini or 200Tdi diesel engine was critical to the success of the Jay vehicle. This is an early production example, with the turbocharger clearly visible.

Although a significant amount of validation testing followed, the Gemini engine team held its collective breath when the first models went out to the media and to customers in the autumn of 1989. By then it had acquired the marketing name of 200Tdi. The ‘200’ was an approximation of its maximum torque figure (195lb ft in Discovery guise), and the letters stood for Turbocharged, Direct-injection, Intercooled.

Jay Prototypes

Translating design into reality was achieved with remarkable speed thanks to the use of Computer Aided Design. Components were not tested in prototype form in the traditional way, then refined until tests were satisfactory. Instead, they were ‘tested’ by computer before they had even been made. Adjustments were then made to the design on the basis of the computer test results, and production tooling was made as soon as the computer was happy with the design. As a result, all the Jay prototypes except the first few hand-built examples made at the end of 1987 were built with production components. So successful was this procedure that only a tiny number of components had to be redesigned when prototype testing – ‘validation’ of the design – showed up failures.

The first off-tools body panels were manufactured in January 1988, less than seventeen months after the Jay project had been given the go-ahead by the Rover Board. Just a couple of months later, as assembly of the components into complete vehicles was ready to begin, a strike at the Land Rover works threatened to hold things up. The members of the Jay Team, however, were disinclined to let this dispute deflect them from their aim. Mike Donovan remembered that the first off-tools bodies were actually assembled by the Jay Team itself and smuggled out of the plant through the picket lines to be painted elsewhere.

It was striking that there had been no significant breach in the secrecy surrounding the new project. All that changed over the summer of 1988. Somebody was able to photograph a full-size model in the Design Studio and sold the results to the media, adding that it was a new ‘baby Range Rover’ known at that stage as Project J. Land Rover set up a major internal enquiry, appointing as its head John Stalker, the former Deputy Chief Constable of the Greater Manchester Police who had led an enquiry into shootings of civilians in Ireland in 1983. The culprit was never found.

Media interest began to intensify after the appearance of those photographs, however, which Land Rover countered by claiming that they represented an earlier state of design. This was certainly true, but the knowledge that a new model was on the way led to speculation about the new ‘baby Range Rover’. Then, as disguised prototypes began to appear in the usual locations, some were photographed. The pictures appeared in magazines, accompanied by speculative stories.

In total, more than fifty Jay prototypes would be built before the vehicle was signed-off for production. The first group of prototypes was used for validation of the design, and all were hand-built by engineering fitters. The second group was distinguished by its greater number of off-tools parts and was built on the assembly line by assembly staff, thus validating manufacturability, processes and facilities. Both groups included petrol and diesel examples, and vehicles from both groups were crash-tested at MIRA.

Some went out on the roads, wearing GRP disguise panels that gave them the appearance (from a distance, anyway) of a Range Rover van, and among these were a blue vehicle, which went to Australia for hot-climate testing, and a white one, which went to Canada for cold-climate work. Several prototypes were registered for road use in Britain, where they received C-prefix and D-prefix number plates dating from 1985 and 1986 to avoid attracting attention. The deception was compounded in some cases by the registration documents, which described them as Austin Maestros! Meanwhile, accessories that Land Rover planned to offer for the vehicle were included in the main validation programme.

The last stage in the prototype process was the production of between twenty and twenty-five pilot-production vehicles in the early part of 1989. These were known as SDVs (Specially Designated Vehicles) and were handed over to various departments within Land Rover that either would be or had already been involved with Jay. Some became the subjects of the first publicity photographs of the new vehicle.

One of the last tasks was to find a name for the new vehicle. The Jay Team started with 842 possibilities, which were gradually whittled down to a short list of fifteen, and these were tested out at customer clinics. Some particularly good ones were put aside for possible use on future products, but the final choice of Discovery was a clear favourite – even though it was already in use as the code name for the new Range Rover project. That had to be renamed in 1989 as a result, and became Pegasus.

This was the proposal for the ‘van’ camouflage, drawn up by Tony Poole in Advanced Design.

Wearing its van disguise, Range Rover-style wheels and black paint to camouflage the front-end design, this preproduction vehicle went out to Canada for cold-climate testing in late 1988. It had VIN SALLJGBV8EA-329069, used an injected V8 engine, and was number Jay 5 on the engineering fleet. Now registered as B62 COH, it still survives in the Dunsfold Collection.

The ‘van’ disguise could be lifted on and off the vehicle, as seen in these pictures of the Canadian cold-climate test vehicle, Jay 5.

Not the least important elements in the appeal of the Discovery name were that it was easy to pronounce in all languages and already carried its own familiarity and image worldwide because of the space discovery programme. For English speakers, it also had a resonance suggesting excitement and adventure – ideal to boost the image of a family vehicle and also ideal to reflect one of the core Land Rover brand strengths.

The launch was now on target for autumn 1989. Project Jay had been an extraordinary achievement in motor industry terms, having brought a new vehicle to market in just over two-and-a-half years and having cost a relatively paltry £45 million. Land Rover managers were themselves quite flabbergasted by what the company had achieved, and one anecdote sums up their amazement perfectly. Commercial Director Chris Woodwark had the job of introducing the Discovery to the media when it was announced at the Frankfurt show in September 1989. When preparing his speech he began to wonder whether anybody would believe how little the Discovery had cost to develop, so he added £100 million to the real figure. The assembled media and industry still thought the Discovery had been a bargain.

Photographed at Uluru (then known as Ayers Rock) in central Australia, this was another camouflaged pre-production test vehicle. The overhead shot was also taken during its hot-climate testing on that continent.

The motoring press did capture some photographs of the new model on test. This one was spotted in the USA; the magazine assumed that it was a mini-Range Rover, and called it ‘Project J’.

CHAPTER TWO

THE ORIGINAL DISCOVERY, 1990–94

The 1989 Frankfurt Show had been chosen to showcase not only the Discovery itself but also to demonstrate that Land Rover saw this as a vehicle for world markets. An important element in the launch strategy was to make the new model appear as different as possible from the Range Rover, so only the three-door Discovery was announced at Frankfurt on 12 September. Associated publicity depicted the new Discovery as a model for a younger group of buyers, who would see ownership of the vehicle as making a statement about their carefree, fashionable lifestyles.

The need to distinguish the Discovery from its parent also explained why these first examples had a 144bhp carburettor 3.5-litre V8 petrol engine, while the Range Rover switched to a 185bhp 3.9-litre type with fuel injection, and why the Discovery had no automatic gearbox option. These were purely marketing ploys, but they worked. In Europe, the focus on the new Tdi diesel engine also helped, and most potential buyers perceived the Discovery as a completely separate model from the Range Rover. The association was always there in the background, though, and when the first second-hand Discoverys reached the market a few months after the launch, they were often described in advertisements as Range Rover Discoverys. This certainly helped sellers talk the prices upwards.

These first Discoverys all came with Sonar Blue interior trim, which was certainly distinctive but hardly sophisticated, and with the garish side stripes that had been inspired by similar decal treatments on Japanese 4 × 4s sold in Europe. There were no alloy wheels at first, and although Land Rover Parts put some five-spoke items onto the market as soon as it could, these could not be ordered as a line-fitted option.

The first production Discovery has always belonged to the Heritage Collection. It originally carried the number plate G794 BKV, but this was found to be an error and the vehicle was re-registered with an age-related plate in 2012.

The Discovery also had impeccable off-road credentials: it was a Land Rover, after all. This one was about to demonstrate the fact at the Val d’Isère off-road course, high in the French Alps.

The torquey and economical 200Tdi diesel engine was the making of the Discovery in the early days, although by later standards it was crude and noisy.

The carburettor V8 petrol engine was available for only the first year of production.

This, of course, was reflected in the marketing strategy adopted for the Discovery. The bargain-basement price of £15,750 for either V8 or Tdi versions in the UK looked extremely attractive, but it was usually heavily inflated by a number of line-build options (see below) and by various accessories from Land Rover Parts. In the words of the 1989 press release, these

included items designed to protect the exterior and interior of the vehicle plus external utility accessories such as sports equipment carriers, sporting wheels, lighting, winching and towing accessories. In addition, there are high-tech items such as cellular telephones which are compatible with fax and data communication machines and a compact disc player featuring multi disc selection.

That marketing strategy went much further than anything Land Rover had done before. Following in the footsteps of a number of European luxury car makers, Land Rover had chosen to foster brand awareness and brand loyalty (as well as making a little extra money) by having Land Rover Parts sell a whole range of leisurewear and gifts bearing the Discovery logo. These included a key ring, roller-ball pens, sports holdalls, ski jackets and beach towels, a picnic basket and an umbrella. They were aimed, said the press release, ‘at the active family’. This was a very different style of marketing from that associated with the utility Land Rovers and with the Range Rover, and it opened a new era for the company. In due course, the other two model ranges would also benefit from a selection of non-vehicular accessories.

The original Sonar Blue interior was fresh and modern, but looked dated within a few years.

Even Land Rover’s dealerships had invested heavily in the new vehicle, which of course hinted at a bright new future for them as well as for the parent company. As Rover Group Managing Director George Simpson told journalists at a briefing just a few hours before the Discovery was unveiled at the Frankfurt Show in 1989: