Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: The Crowood Press

- Kategorie: Lebensstil

- Sprache: Englisch

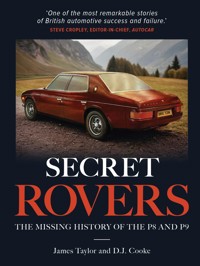

Like other British motor manufacturers, the Rover Company spent World War II helping the war effort rather than building cars. Bombed out of its original home in Coventry during the Blitz in 1940, it was fortunate in 1945 to be able to move into the new factory at Solihull that it had been managing on behalf of the Air Ministry. The Solihull factory was not only new: it was huge. Its size presented Rover with a welcome opportunity for expansion, but first the company had to get back into the game. With no new car designs ready, Rover's only option was to re-start production with mildly improved versions of their pre-war models. New models were a long time coming. Early ideas focused on a small economy car, but it soon became clear that this was not what the public wanted. Meanwhile, ambitious plans for a new and ultra-modern car, using mechanical elements that had been under development before the war, had to be put back when there were delays in designing a satisfactory modern body style. As a temporary measure, Rover added their new mechanical elements to modified pre-war style bodies to deliver the P3 models in 1948. The solution was unexpected. Rover's Chief Engineer had bought a war-surplus Jeep for his own use, and he quickly realised that Rover could easily build something similar that civilian users both at home and abroad would find useful. Combining their new engine with the simplest of chassis and body to save time and costs, Rover had the Land-Rover ready shortly after the new P3 – and its immediate world-wide success took them by surprise. It had plans, too – far too many to put into production. There were gas turbine-powered cars inspired by the company's wartime jet engine work; there was a hybrid of Rover car and Land-Rover called the Road-Rover; and there were ideas for expanding the existing model ranges and adding more. By 1953, when the story told in this book ends, Rover was ready to introduce new saloons and Land-Rovers that would see it comfortably through the 1950s. Not only had it survived, but it was in better health than ever before.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 326

Veröffentlichungsjahr: 2024

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

Contents

Introduction

Timeline

Chapter 1 Background and Overview

Chapter 2 Back in Business, 1946–47

Chapter 3 Inspiration: Small Wonder

Chapter 4 Frustration: The Road to P3

Chapter 5 Evolution: ‘One Of Britain’s Fine Cars – Now Made Finer!’

Chapter 6 Experimentation: Gas Turbines

Chapter 7 Revolution: The Land-Rover

Chapter 8 A Thoroughly Modern Rover

Chapter 9 Where Next?

Appendix I Who was Who at Rover?

Appendix II The Rover Factories

Appendix III Rover CKD Operations, 1948–53

Appendix IV The Marauder

Appendix V Meteors and Meteorites

Appendix VI Technical Specifications

Index

Introduction

When peace returned to Britain at the end of World War II in 1945, Britain’s car manufacturers were faced with the task of getting back into their traditional business after six years of focusing on producing war matériel. It was not easy and, for Rover, was complicated by the decision to move into a new factory some fifteen miles west of their old one.

The first job was to get back into making cars, and only after that was there time to develop new designs. For Rover, the process of creating a new model that met their standards was a long and difficult one, complicated by the government’s insistence that they should prioritise models that would sell well outside Britain. For a small company that had never given much thought to exports before, this was a very tall order.

Yet in these difficult times, Rover fell back on the combination of sound business management and engineering expertise that had helped it avoid collapse in the early 1930s. In fact, the pressure of those difficult times led to a new tradition for Rover, of having far more new ideas than they could reasonably put into production. Many of them were innovative, and would go on to give the company a unique and much respected position within the British motor industry in the two decades after the war.

Studies of Rover’s products in that period have tended to focus on individual types, such as the P4 saloons or the Land-Rover. This approach unavoidably minimises the interdependency of the company’s products, which played an important part in their remarkable renaissance. The critical period in the post-war era was the years 1945–1953, and it is this period and its products that this book covers. In 1945 Rover was really starting from almost nothing, and by 1953 they were once again on a sound footing and were looking at further expansion.

James Taylor

Oxfordshire

November 2023

Timeline

1944 First work on proposed new post-war Model M.

1945 Work recommences on IOE engines and box-section chassis planned before the war.

Rover moves into Solihull factory. Production of lightly revised pre-war cars begins.

1946 Design work on new bodies runs into difficulties. First Model M prototypes. Re-orientation of design work now aims for an interim model (P3) and a second more modern model (P4).

1947 Model M abandoned in favour of Land-Rover. Studebakers obtained from USA to assist P4 development.

1948 P3 saloons replace revised pre-war types (February). Land-Rover introduced (April). First overseas assembly operations begin.

1949 P4 saloons replace P3 models. 100bhp gas turbine engine runs. Land-Rover production and sales exceed those of Rover cars.

1950 Demonstration runs of first gas turbine car prototype (JET 1).

1951 First work on a more conventional gas turbine car. First work on Road-Rover project.

1952 JET 1 sets a record 152mph (245km/h) at Jabbeke. New share issue brings in finance for major expansion plans.

1953 Gas turbine department becomes Rover Gas Turbines Ltd. First work on new smaller Rover saloon with V6 engine. Rover introduce four new models: 60 and 90 saloons, and 86 and 107 Land-Rovers.

CHAPTER 1

Background and Overview

By the time World War II began in September 1939, the Rover Company enjoyed a solid reputation in Britain as the makers of ‘One of Britain’s Fine Cars’. The slogan dated from 1936, by which time the company had emerged from a difficult financial period in the early years of the decade and had begun to earn the lasting respect of the professional classes for whom its cars were mostly built.

S. B. Wilks was the level-headed managing director on whose guidance the Rover Company depended heavily.

Rover in this period was based in Coventry, with its main factory and headquarters at Helen Street in the Stoke Heath (now Foleshill) district to the northeast of the city centre. It had an exceptionally strong management team, with the board of directors led by Ransom Harrison, Howe Graham as financial director, and S. B. (Spencer) Wilks as managing director. Chief engineer was Maurice Wilks, the younger brother of the managing director, and he oversaw an equally strong team of engineers. Rover was an independent company, quite small by motor industry standards, but it was run almost like a family business and engendered great loyalty from its employees. By the end of the 1930s, it was selling between 10,000 and 11,000 cars a year.

World War II brought this idyllic existence to an abrupt end. Rover introduced their 1940- model cars as planned in September 1939, but had already turned part of their manufacturing capability over to repairing military aircraft. Since the middle of the decade, they had been running a ‘shadow factory’ at Acocks Green, building aero engines for military use, and during 1939 they took on the management of a second one, at Solihull to the southeast of Birmingham. Car production was halted on government orders in May 1940, and the entire resources of the company were redirected to the war effort. The Helen Street factory was severely damaged by enemy bombing in the Coventry Blitz in November 1940, and the Rover staff dispersed – some of them to a group of repurposed cotton mills in Lancashire and Yorkshire, where they assisted Frank Whittle with the development of his jet engine for aircraft.

Maurice Wilks was the enthusiastic and innovative driving force behind Rover engineering.

It was not until June 1944, as the D-Day landings made clear that the tide of war in Europe was turning, that Rover was able to contemplate with any clarity its future as a car manufacturer. No new design work had been done during the war years, although new models had been planned before the war and the work done for them had not been lost. The Helen Street factory in Coventry had been hastily patched up to enable it to continue producing war matériel, but there was a tantalising alternative to returning there. The Solihull factory was much newer, more modern, and larger, and the government had offered Rover first refusal on it once it was no longer needed for war work.

This poor-quality photograph is the only known picture of the Rover Board as it was in 1945. In the centre is Ransom Harrison, the chairman. On the left are George Farmer (assistant secretary and chief accountant), Frank Ward (secretary) and S. B. Wilks (managing director). On the right are Howe Graham (vice-chairman) and Sir Geoffrey Savage (works director).

Rover’s initial offer to buy the factory outright was rejected, but subsequent discussions about a long-term lease proved fruitful. In February 1945, the Rover Board agreed to lease the factory and to dispose of the Helen Street works, which was sold in July to the Coventry machine tool makers Alfred Herbert. By March, Rover had begun to move into their new Solihull headquarters.

A New Dawn

As early as 1944, the company had also begun to think about the cars it would be selling once peace returned. There were still many unknowns, of course, and whatever plans they developed would have to be modified in the light of events. No surviving documents tell us who took the responsibility for this aspect of company planning, but the strong probability is that the Wilks brothers took the lead. As managing director, S. B. Wilks was used to setting the direction that Rover should take, and he could not have done so at this stage without consulting his brother who, as chief engineer, knew what the company had been working on before the war and what was likely to be feasible.

It was inevitable that both men should have considered the company’s previous experience in similar circumstances, and should have looked at what happened immediately after the end of World War I. The period immediately after 1919 had seen a strong demand for small and inexpensive cars, and there was every reason to imagine that the same would happen again. The British economy was likely to remain in the doldrums for at least a few years, which argued against Rover relying on the sort of expensive, high-quality cars that they had been building for the professional classes in the late 1930s. Similarly, there would be many returning servicemen who wanted to start a new life and would see car ownership as part of that, but who would initially only be able to afford a secondhand one or an inexpensive new one.

Rover’s first thoughts for a new model turned to an economy-focused small car, the M Model, of which a handful of prototypes were built in 1946.

It was quite clear to Rover management that the company would be wise to enter the postwar market with a small economy car, perhaps alongside a more traditional Rover or perhaps instead of it for a time. So early thoughts in 1944 were focused on the design of such a machine, and between then and the middle of 1946 the Rover designers and engineers put a great deal of effort into what became known as the M Model. This was a small car, intended for the cheapest 6hp class and essentially a two-seater (although space for children in the rear was also found as the design progressed). The M Model was eventually cancelled before entering production but, as Chapter 3 makes clear, the need to design it brought out considerable inventiveness and ingenuity in the Rover team.

Of course, the M Model was not and could not have been ready for production by the time peace came in May 1945. Although the war still rumbled on in the Far East, it was clear that Europe could begin to return to normality – although it would be a new version of that normality – and that the government would once again permit car production as the need to produce war matériel receded. Rover did not have a new car ready to enter production, and so it did the same as other makers were obliged to do: it made plans to put the cars that it had been building in 1940 back into production until such time as it had something newer to offer.

That was very much easier said than done. At least Rover was fortunate that the jigs and tools associated with the 1940 models had survived the bombing of the Helen Street factory. They were, however, located in Coventry, and Rover planned to restart production at the Solihull factory to which it would relocate entirely during 1945. So, over a period of eight months between March and November that year, the Rover works engineers transported the production tooling and the assembly lines from Coventry to Solihull, where they set it all up and made it ready for use again.

Rover also looked back at the plans for new models it had been working on when car production was halted by the war during 1940. Plans for the 1941-season and later cars had been quite well advanced, and the new Rovers were intended to have a sturdy new box-section chassis frame, plus new and highly efficient engines with an inlet-over-exhaust valve arrangement and a sloping cylinder head face. Some ideas for new body designs had also been worked up to the full-size mock-up stage. None of this was lost; all of it could be gathered together and would feed into the thinking about the new full-size post-war Rover saloons. But it could not happen yet. The market had to recover, and Rover had to recover. Nevertheless, as Chapter 4 explains, there is clear evidence that the company began work on those new cars as early as November 1945. They knew them in the beginning as Model P.

Rover’s post-war home at Solihull was a factory that had been built to produce aero engine components during World War II.

After the hiatus of the war, Rover re-started manufacture of their pre-war cars. These six-light Saloon models were photographed in front of the main building at Solihull, which still bears traces of wartime camouflage paint. They had been built on the assembly lines that lay behind the administrative offices at the front of the building.

Diversification

In addition to work on the Model M and Model P cars, there was a third strand to Rover product development as 1945 came to an end. Between 1940 and 1943, several of the company’s senior engineers had been seconded to the jet engine project led by Frank Whittle, and had come to understand these engines very well. Among them had been Maurice Wilks, who had led a team that had redesigned the Whittle engine for greater efficiency, and it had been a development of the Rover-designed engine that had eventually entered production to give Britain its first jet engine. By then, the jet engine work had been handed over to Rolls-Royce, at least partly to prevent strife between Whittle and the Rover people slowing progress on a project seen as vital to Britain’s war effort. But Maurice Wilks had not forgotten the experience, and by late 1945 he had gained agreement within Rover that the company should investigate the use of a jet engine – re-named the gas turbine in this instance – to power a road car. This enthusiasm for investigating new avenues of engineering was absolutely typical of the man, and would come to characterise the whole of Rover for many years.

The year 1946 was a critical one for Rover. The company was settling into its new home at Solihull, and on 2 February Sir Stafford Cripps, the President of the Board of Trade, visited the factory to open it officially. Progress on Model M and Model P was slow, and although the first prototypes of Model M would be running by the late summer, the body design for Model P had encountered a number of setbacks. Materials shortages were causing major problems for manufacturing industry, and were behind S. B. Wilks’ decision not to introduce the new engines as an interim measure to add appeal to the existing Rover saloon range for 1947.

Developments in the US motor industry also had their effect on Rover’s plans, and none more so than the introduction in summer 1946 of the 1947-model Studebakers. Maurice Wilks and production chief Olaf Poppe were already keeping an eye on developments in the USA, and during 1946 they obtained first a Buick and then an Oldsmobile of unspecified type to examine. The US dimension was important, because the American motor industry was some way ahead of its European counterpart at this stage. US car production had not been suspended until 1942, which had allowed two whole years of advance to be made. The US car industry was also able to get back into production with new designs far more quickly than the European industry, and seized the opportunity for yet further advances.

These advances were not only in engineering but also in styling – and in summer 1946 the Studebaker marque stole a march on its rivals by introducing a new approach. Instead of the traditional two-box design that consisted of bonnet and passenger cabin, it announced its 1947 models with a three-box design, where the projecting bonnet was visually balanced by a projecting boot. Though this new approach was controversial, it was an unmistakeable pointer to a new future. It must also have made clear to Maurice Wilks that all the body designs for the new Rover that he had come up with so far had become old-fashioned overnight.

It must also have been very obvious that creating an acceptable modern body style for the planned new Rover was going to take time. Other British manufacturers were already working on new models and Rover could not afford to delay in putting something new on the market. So a plan came together for a stopgap product – an interim saloon that would get something new into the showrooms to retain customer interest while the all-new Rover was being prepared. Rover already had those pre-war designs for a new chassis and a new engine, and by making minimal but valuable alterations to the body design already in production would be able to get a new car ready by early 1948. They gave it the name of P3: Model P had been the original plan for a new saloon, the revived pre-war cars now became P2, and the new car would become the third post-war Rover.

All of these plans were made against a background of increasing difficulty for the motor industry. When Sir Stafford Cripps had formally opened the Solihull factory in February 1946, his speech to the workforce had impressed upon them the need to build for export. Exports would earn revenue that would help rebuild the British economy that had been so hard hit by the cost of the war. By July, the Board of Trade was talking about allocating raw materials – in particular, sheet steel and timber – to manufacturers in accordance with their export performance. A poor export performance would inevitably lead to a lower supply of raw materials, which in turn would restrict the number of cars a manufacturer could produce. In June 1947, S. B. Wilks attended a meeting with government officials in London where those present were told that companies would be expected to export 50 per cent of their output. Later, that figure would be ratcheted up even higher.

Rover’s policy of staying with a body style that looked so much like its predecessor now began to look risky. The existing production cars were already looking old-fashioned against newer designs that were becoming available in the export markets where they were sold, and that position was only likely to worsen. If insufficient exports would lead to a reduced supply of raw materials, Rover was going to be in trouble. It was also becoming clear that buyers both at home and overseas did not really want economy cars like the M Model that Rover was preparing; they wanted larger, more exuberant cars to express their freedom in the new post-war world. As 1946 merged into 1947, it was clear that Rover was illprepared for the future. If the company was to survive, it needed a new model with guaranteed export appeal that would keep sales alive until the all-new post-war saloon could be introduced. The solution was not one that anyone could have foreseen. As Chapter 7 explains, Maurice Wilks had obtained a war-surplus military Jeep to help with domestic tasks and for his own amusement. He was struck by how useful it was, and from there to the realisation that there would be a good market for a civilianised equivalent was a small step. Better yet, he knew that new and existing Rover components could be used to create such a vehicle, and that it would not be very difficult to design the other essential elements. By the late summer of 1947, Rover’s product plan had therefore been turned on its head. The M Model would not after all go into production. The stopgap P3 model would be prepared for 1948 but its all-new replacement (the P4) would be put into production as soon as humanly possible after that. And the new utility runabout, which gained the name of Land-Rover, would also enter production in 1948 to keep Rover’s export quotas up to the required levels.

Building Up Production

One of S. B. Wilks’ preoccupations in this period was with increasing Rover production. He had seen the opportunities for increased overall output that the large new factory at Solihull offered, and from the start he envisaged the production of the Model M 6hp cars as additional to the output of full-size Rovers. In August 1946, he told the Rover Board that he wanted to plan for 12–15,000 full-size cars a year, with 5,000 6hp types on top of that total. This was ambitious: it set Rover on track for nearly doubling its pre-war output.

It would be a long time before reality caught up with this vision. Wilks’ regular reports to the Board show just how difficult it was to get production numbers up in the post-war climate of materials shortages. In January 1946, production was running at about 30 cars a week; by March it was 70 a week but not consistently; and by May, Rover was making 100 cars a week. The totals steadily increased after that – to 120 a week in July, 135 a week in August and 155 a week in October. By May 1947, Wilks was aiming for 200 a week, but the best so far was 184. The figure of 200 a week was achieved by September, but supply difficulties were limiting further increases. Then in October 1947, Wilks told the Board that he hoped the start of Land-Rover production in spring 1948 would add a further 100 units a week to the factory’s output. In due course, it would vastly exceed that; by early 1952 Land-Rover production had reached 400 units a week.

The early months of 1948 must have been both busy and pressured at Solihull, as the company scrambled to get first the new P3 saloons into production and then the new Land-Rover. The P3 cars were announced at the Brussels Autosalon in February, and the Land-Rover at the Amsterdam Show at the end of April. Production took a little time to catch up: full production of all the car variants was not achieved until May, and quantity production of Land-Rovers did not begin until June.

The P3 models did not exactly set the Thames on fire. Although British magazines made loyal noises about the continuation of great British traditions, the feedback from the European continent was that the cars were rather old-fashioned. First-year sales of a little over 6,000 cars were only about 75 per cent of the 8,220 examples of the revived pre-war range that Rover had sold during 1947. The Land-Rover, on the other hand, was a much bigger success than the company had ever imagined. Orders simply poured in after the Amsterdam Show, and by the end of the year the chairman was able to tell the Rover Annual General Meeting that:

the orders and enquiries we have already received, particularly from overseas, indicate that this vehicle will be something very much more than an additional source of production. It may yet equal – and even exceed – our car output in quantity.

EXTRA-CURRICULAR ACTIVITIES

Spare-time activity: this is the Djinn single-seater, with Rover engineer Gordon Bashford on the left.

The Mezzolitre was another club racer built as a spare-time activity. Gordon Bashford is second from the right here.

Most famous of all the club racers associated with Rover engineers was the Rover Special, which was based on the chassis of a Rover prototype.

Despite the restrictions of the austerity period in late-1940s Britain, the enthusiasm of Rover’s engineers was undimmed. Outside working hours, chassis designer Gordon Bashford was involved in the design and preparation of two single-seat club racers – the 1100cc Djinn and the 500cc Mezzolitre. His colleagues Spen King, George Mackie and Peter Wilks meanwhile created their own Rover Special single-seater from a redundant Rover prototype (seeChapter 5) and campaigned it with some success.

Unhappy with early designs for a new post-war saloon, Rover used their new chassis and engines under a body that continued the pre-war styling. This is a 1949 four-light P3 model.

The product that ensured Rover’s future was a most unlikely one – the utility Land-Rover could hardly have been more different from Rover’s refined saloons, but it shared some of their engineering and found a ready market all over the world. This was one of many thousands sold in Australia.

Exports were vital to survival, and there was a ready market in the colonies. This was how the P3 was advertised in Australia.

Britain’s Most Versatile Vehicle took Rover into an area of the market that they had never explored before – but the company soon caught up. This advertisement appeared in The Field magazine for May 1953.

It did both, and this solid success was followed in the autumn of 1949 by the overdue introduction of the Rover P4 models, the modern Rovers that Maurice Wilks had been trying to achieve since the end of the war. Initial production was hindered by the usual materials shortages, and also by the fact that (just as with the Land-Rover), the launch had actually taken place before the car had been fully developed. Yet the new car was well received. Production and sales built up alongside booming demand for Land-Rovers, and this was supplemented by several overseas assembly operations (which are described in Appendix III). By 1951, Rover was certainly firmly planted back on its feet, and appeared to have a rosy future.

These two strands of revenue-earning activity were supported by a third, because Rover was still producing tank engines on behalf of the government at its Acocks Green factory (seeAppendix V). There was a fourth one waiting in the wings, in the shape of the gas turbine development work, and before long the ever-enthusiastic Maurice Wilks came up with another new idea for a vehicle that Rover could manufacture.

This time, it was a rugged estate-type vehicle aimed at the farmer’s wife, a hybrid of car and Land-Rover that he called the Road-Rover (seeChapter 9). So, yet another development project was put in place. This meant that from 1951 Rover’s efforts were spread across cars, Land-Rovers, tank engines, gas turbines and the Road-Rover. Most of this was in effect funded by the success of the Land-Rover, but it was a lot for one relatively small company to have on at once, especially as the booming success of the Land-Rover was already calling for further expansion of the manufacturing facilities. Trying to do too much became a Rover characteristic that would endure throughout the 1950s and 1960s, and it would only be curbed after the company became part of British Leyland in 1968.

When the real new post-war Rover arrived in late 1949, it was so different from anything that the company had done before that many conservative-minded buyers were quite upset.

An early P4 model became the first gas turbine Rover prototype. Here it is, with the team that built it.

Gas turbine propulsion was new and exciting, and Rover gained valuable publicity by going public with news of their work.The car was awarded the prestigious RAC Dewar Trophy for outstanding British technical achievement in the automotive industry.

Nevertheless, level-headed management by the Rover Board coped admirably with all this activity. The need for more Land-Rover manufacturing facilities was addressed during 1952 when the company bought new premises at Perry Barr and at Springfield and expanded its London Service Depot at Seagrave Road by buying adjacent premises. (There is more detail about all these sites in Appendix II.) Plans to erect a further 80,000sq ft building at Solihull were also approved, but were deferred because of a worsening financial climate.

British sports cars cracked the American market, but saloons were less successful. Rover piggy-backed on the Rootes Group’s export organisation at first, as this advertisement for the P4 placed by a major Californian car agency shows.

In mid-1952, a new share issue brought in the finance needed for an ambitious expansion plan that also incorporated some more new products. The expansion programme for the twelve months between August 1952 and August 1953 embraced the introduction of two new variants of the Rover saloon range (the 60 and the 90), two Land-Rover models (the 86 and the 107) to replace the single existing one, and the Road- Rover. In addition, it would cover the start of gas turbine engine production (initially as auxiliary power plants – seeChapter 6). And, as Chapter 9 explains, Maurice Wilks was already focusing on another new range of cars and engines before the end of 1953, as well as on special-bodied derivatives of the existing cars. The seemingly unflappable Board once again coped with all of this, and during 1953 decided it would be wise to increase its membership maximum from seven to twelve directors – a proposal that would be discussed at the Annual General Meeting at the end of the year.

This early 1950s picture inside the Rover works shows an early Land-Rover and an eclectic group of three competitor vehicles that the company had bought for evaluation. They are a Citroën 2CV, a Porsche 356 and a Panhard Dyna. Just visible on the right is the front wing of a Road-Rover prototype.

Taken probably inside the Rover Service Department, this picture shows several P3 models from the late 1940s and (second from left) a solitary P4.

‘To the casual glance two more dissimilar vehicles could not be imagined.’ Cars and Land-Rovers tended to be advertised separately, but there were a few instances where they appeared together. This advertisement was placed in the illustrated London news of June 1953. It is easy now to forget the heritage behind the hugely successful Land-Rover, not least because that marque survives but Rover ceased to exist in 2005.

All this was happening at Rover against a social and economic background that had still not fully recovered from the war years and the subsequent period of austerity. Clothes were rationed until 1949, and both soap and petrol were rationed until 1950. New private cars had been scarce in Britain thanks to the Government’s insistence on giving priority to exports, and although restrictions were easing, some were still in place. A huge increase in purchase tax in the 1951 Budget threatened sales of many of the more expensive cars. Exports were still top of the priorities in 1952, and although the Home Quota for both cars and Land-Rovers was increased in the middle of the year, production totals of the basic Land- Rover for the 1953 season were some 20 per cent down as compared to 1952. Britain was not out of the woods yet – but Rover was thriving and was more than ready to face the challenges of the new decade.

Export requirements introduced some new procedures to Rover. These left-hand-drive models were pictured on the dockside before being loaded aboard the cargo ship that would take them to their destination. They are fitted with ‘slave’ tyres made of wooden blocks; the real thing would be fitted at the end of their journey.

Journey’s end – almost. This group of Land-Rovers has been unloaded at docks in India and will now be transported, in most cases by rail, to the ordering dealers.

From autumn 1953, the wheelbase size of the basic Land-Rover was increased to 86in, and the rear overhang was lengthened to provide greater load space. A new seven-seat Station Wagon, seen here, followed soon after.

Also from autumn 1953, a long-wheelbase companion model on a 107in wheelbase was introduced. It was specifically designed as a load-carrier, with a 6ft long load bed.

At the same time as two new Land-Rover models appeared, so did two new variants of the P4 saloon, the 60 and the 90. This view of a 60 shows two key interior changes – to a side-mounted handbrake and a floor-mounted gearchange. The handbrake later went back to its earlier position.

PRODUCTION FIGURES, 1946–53

These figures are for the Rover ‘production year’, which did not usually correspond directly with the calendar year. The production year for Rover cars and for Land-Rovers was not always the same, and the figures in the ‘Total’ column should therefore be treated with caution, although they do give a good idea of the company’s health for each year. The car production figures for 1951 were artificially inflated by a long model-year.

1946The production year corresponded to the calendar year, but the production figure shown includes a handful of cars completed in December 1945.

1947Production year figures appear to correspond to the calendar year, plus January 1948 (13 months).

1948The car production year ran from February to December 1948. The Land-Rover production year ran from March 1948 to March 1949.

1949The car production year ran from January 1949 to July or August 1949. The Land-Rover production year ran from February to July 1949.

1950The car production year ran from September 1949 to August 1950. The Land-Rover production year ran from July 1949 to March 1950.

1951The car production year ran from September 1950 to December 1951. The Land-Rover production year ran from September 1950 to August 1951.

1952The car production year ran from January 1952 to August (September?) 1952. The Land-Rover production year ran from July 1951 to August 1952.

1953The car production year ran from October 1952 to July 1953. The Land-Rover production year ran from September 1952 to August 1953.

The early 1950s saw the first tentative steps to create a model called the Road-Rover. It never did make production, but was an interesting hybrid of Rover car and Land-Rover thinking. This is believed to be the first prototype.

CHAPTER 2

Back in Business, 1946–47

World War II was drawing slowly to a close by the start of 1945, when the British government issued permits for car manufacture to begin again. At their meeting on 15 January, the members of the Rover Board learned that they had been granted a permit to build 1,100 cars, or just over 10 per cent of their typical annual output by the end of the 1930s. It was not a lot, but the chances of achieving even that small number looked very slim.

The post-war chassis was barely altered from the one that Rover had been building when war broke out in 1939. This chassis of a 1940-model Twelve was typical.

As most of the tooling for the 1940-model Rovers had been put into storage for the duration of hostilities, the decision about what to do more or less made itself. There was in any case no other realistic option if Rover wanted to get back into business quickly: even though plans for new models were in their early stages, these would take time to be developed into viable production models. Rover would have to re-start manufacture of the cars that they had been building when the war brought production to a halt five years earlier. The company was not alone among British manufacturers in being forced to such a conclusion.

Rover advertising of the period was always discreet, as this rare colour advertisement shows.

On the positive side, it was already clear that by taking over the shadow factory at Solihull that it had been managing for the Ministry of Aircraft Production, Rover could provide for future expansion. The Solihull factory was larger and newer than the old Rover factory at Helen Street in Coventry, and it was well sited for rail and road links (although there would never be a railhead at the factory itself). Rover had already investigated the possibility of buying it outright but the MAP had declined to sell, although they were prepared to consider a long-term lease. So, at its February 1945 meeting, the Rover Board agreed to lease the Solihull factory and to dispose of both the Helen Street works and the small factory at Clay Lane in Coventry. Not mentioned at that meeting, but also important to Rover’s plans, was the Tyseley factory that could be converted back to its pre-war function as an engine and gearbox assembly plant.

So it was that in the eight months between March and November 1945, the Rover Works Engineers moved all the necessary tools and machinery from the company’s old factory in Coventry to its new one in Solihull, and reestablished the company’s production and assembly facilities there. In the meantime, Rover prepared a very much slimmed-down range for production, focusing on the models that they believed would have most appeal in the straitened circumstances of a post-war economy.

The Ten Coupé, the Twenty Sports Saloon and the elegant Salmons-bodied six-cylinder Drophead Coupés of the pre-war range were therefore not revived. The new post-war range would consist of six-light Saloons on the four-cylinder Ten and Twelve and the six-cylinder Fourteen and Sixteen chassis, plus four-light Sports Saloons on the Twelve, Fourteen and Sixteen. All these names reflected the RAC horsepower rating that governed the annual tax payable. Visually, the cars were to be unchanged from their 1940 predecessors. Saloons would have a horn mounted on the left-hand dumb-iron and a pass lamp to match it on the right, while Sports Saloons would retain their centrally mounted pass lamp and twin horns. However, Rover did find time to make a few improvements as well. They changed the double-helical gears in the gearbox to single-helical types and modified the shaft bearing arrangement to suit. On the two six-cylinder chassis, Armstrong dampers with vertical pistons replaced the earlier Luvax type. Prices for these first post-war cars had been agreed by late November 1945, and were inevitably much higher than they had been in 1940: a Ten Saloon that had been £275 now cost £460 even before the new purchase tax was added, and a Sixteen Sports Saloon – which would not be available for some months – last priced at £370 all-in was now £595 before the new tax, which put its price up to £761 0s 7d. These were simply enormous increases.

According to George Oliver (in The Rover), a pilot-production line was set up at the Clay Lane factory at the end of the year, while the Solihull factory was still being prepared for its new role. Here, about 30 staff assembled the first post-war Rovers – all of them four-cylinder Saloons. Oliver notes that a photograph of two Ten Saloons about to leave the Solihull factory appeared in the press towards the end of 1945, and no doubt this was issued to commemorate the start of production. The despatch records confirm that production had actually begun in November, and that the Ten models had been followed before the end of the month by the first Twelves and in December by the first Sixteens. By the end of the year probably around 35 cars had been completed altogether.