Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: Fox Chapel Publishing

- Kategorie: Lebensstil

- Sprache: Englisch

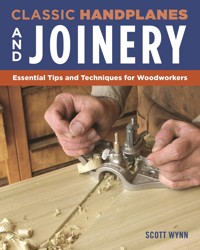

This comprehensive manual on hand-cut joinery provides an essential reference for modern woodworkers and furniture builders. Author and woodworking instructor Scott Wynn shows how to create almost any traditional furniture joint quickly and accurately using hand planes. Readers learn how to choose, set up, maintain, and master the most popular joinery planes, including plow planes, rabbet planes, router planes, shoulder planes, specialty planes, and more. Classic Handplanes and Joinery will teach beginning and intermediate handplane users how to cut perfect dado, groove, rabbet, mortise, and tenon joints. A wonderful guide for any woodworker who is interested in using hand tools, it's loaded with technically rich diagrams, illustrations, practical advice, and skill-building exercises.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 213

Veröffentlichungsjahr: 2018

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

All art is by the author, except for the following: Figure 4-5 courtesy Lie-Nielsen Toolworks, Inc.; Figure 4-6 courtesy Veritas Tools, Inc.; Figure 4-8 courtesy Veritas Tools, Inc.; Figure 4-9 courtesy Stanley Black & Decker, Inc.; Figure 5-3 courtesy Veritas Tools, Inc.

© 2018 by Scott Wynn and Fox Chapel Publishing Company, Inc., 903 Square Street, Mount Joy, PA 17552.

Complete Guide to Wood Joinery is an original work, first published in 2018 by Fox Chapel Publishing Company, Inc. Portions of this book appeared in Woodworkers Guide to Handplanes (978-1-56523-453-6) and Discovering Japanese Handplanes (978-1-56523-886-2), both by Scott Wynn. The drawings and illustrations by the author contained herein are copyrighted by the author. Readers may make copies of them for personal use. The drawings and illustrations themselves, however, are not to be duplicated for resale or distribution under any circumstances. Any such copying is a violation of copyright law.

Print ISBN 978-1-56523-962-3

eISBN 978-1-60765-538-1

Library of Congress Cataloging-in-Publication Data

Names: Wynn, Scott, author.

Title: Classic handplanes and joinery / Scott Wynn.

Description: Mount Joy : Fox Chapel Publishing, [2018] | Includes index.

Identifiers: LCCN 2018025435 (print) | LCCN 2018026341 (ebook) | ISBN 9781607655381 (ebook) | ISBN 9781565239623

Subjects: LCSH: Joinery. | Woodwork.

Classification: LCC TH5662 (ebook) | LCC TH5662 .W96 2018 (print) | DDC 694/.6--dc23

LC record available at https://lccn.loc.gov/2018025435

To learn more about the other great books from Fox Chapel Publishing, or to find a retailer near you, call toll-free 800-457-9112 or visit us at www.FoxChapelPublishing.com.

We are always looking for talented authors. To submit an idea, please send a brief inquiry to [email protected].

Contents

INTRODUCTION

PART 1: THE BASICS

CHAPTER 1: STEEL

Anatomy of Steel

Types of Edge Steel

CHAPTER 2: UNDERSTANDING HOW A PLANE WORKS

The Tactics

The Angle of the Blade

Mouth Opening

Chipbreaker

Bevel Angle

Shape of the Blade Edge

Length of Plane/Width of Blade

CHAPTER 3: PLANE SETUP

Inspect the Plane

Prepare the Blade

Prepare the Chipbreaker

Bed the Blade Properly

Configure the Sole

Check the Sole

Adjust the Mouth

PART 2: THE PLANES

CHAPTER 4: RABBET PLANES

The Basic Rabbet Plane

Rabbet Bench and Block Planes

Skewed-Blade Rabbet Planes

The Stanley Rabbet Planes

Which One?

Using the Rabbet Plane

Setting Up Rabbet Planes

CHAPTER 5: FILLISTER AND MOVING-FILLISTER PLANES

Choosing Your Fillister Plane

Fence Solutions

Setting Up the Moving-Fillister Plane

Using the Moving-Fillister Plane

CHAPTER 6: PLOUGH AND DADO PLANES

Using the Plough and Dado

CHAPTER 7: SHOULDER PLANES

Using the Shoulder Plane

CHAPTER 8: BULLNOSE AND CHISEL PLANES

Using Bullnose and Chisel Planes

CHAPTER 9: THE ROUTER PLANE

The Stanley #71 Router Plane

Other Router Plane Options

Using the Router Plane

CHAPTER 10: SIDE-RABBET PLANES

CHAPTER 11: THE DOVETAIL PLANE

CHAPTER 12: THE MORTISE PLANE

PART 3: THE PROJECTS

CHAPTER 13: MAKING A DOVETAIL PLANE

Creating the Plane

Making a Fence

Securing the Fence with Wedges

CHAPTER 14: MAKING AND USING SHOOTING BOARDS

Designing a Shooting Board

Styles of Shooting Boards

Using a Shooting Board

The Dovetailed Stop

Typical Japanese Shouldered-Blade Rabbet Plane here

Classic Simple Moving-Fillister Plane here

Classic Traditional Wood Plough Plane here

INTRODUCTION

The planes described in this book were originally created for making joints—grooves, rabbets, dovetails, and gains for hardware. We now usually use power tools to make these joints, but these planes remain irreplaceable. They can achieve a good fit on a wide variety of joints and also make joints that might otherwise be difficult or impossible with power machinery. These planes are so good at this that I believe they are indispensable for doing high-quality work.

For instance, say you cut a groove in a wide panel for a hardwood plywood partition. First of all, you can’t use a ¾" (19mm) dado head on your table saw because hardwood plywood is less than ¾" (19mm) thick; it is 23/32" (18mm) thick, to be exact—except when it’s not. Industry tolerances allow up to a 1/32" (0.8mm) variance in thickness, so some parts of your panel are thicker than others and your partition doesn’t go into its slot. What do you do? Try to shift your router fence less than 1/32" (0.8mm) to try to get your specialty 23/32" (18mm) router bit to cut a bare fraction more? The easiest thing to do is make a pass or two with your side rabbet plane until that partition slides in. You can even use your side rabbet plane to only widen the groove in areas where the panel is thickest, so you don’t end up with gaps along its length.

Sometimes you cut a groove in a panel or piece, and your partition goes in but not all the way; apparently the panel rode up slightly off the saw or router table top and the cut was not made full depth in some places. This is really common. If you run the piece over the table saw again, you run the risk of widening the cut. If you use your router plane, you can trim the dado to an exact depth for its entire length.

There are myriad uses for these planes that will get you a fine fit in a short amount of time. Sometimes these planes are not just the best option—they may be the only option for a good job.

As a woodworker it is really useful—perhaps mandatory—to know at least a little bit about blade steel. That bit of cutting edge is the direct extension of the image carried in your mind, shaping wood as you’re visualizing it, constantly evaluating, re-analyzing, and revising in a feedback loop. This bit of cutting edge can work with you or it can be indifferent—or worse. Knowing what steel the blades in your planes are made of will help you understand that blade’s abilities, limitations, and potential, how to best sharpen it, and, if you have the option, what might be the best steel for the kind of use to which you’re putting the plane.

While with a joinery plane there may be few options beyond using the blade the plane came with, you can still sometimes find a few alternatives. You may be able to use a blade from a different period of manufacture as the manufacturer may have changed their steel over time; or a different manufacturer may have used a different steel at the same time period and the blade may be interchangeable. You could also be ambitious and make your own blades. And, for instance, some manufacturers, such as Veritas, now offer a choice of O1, A2, or PM-V11 steel for many of their blades.

Wait, wait . . . what is this alpha-numeric soup? Read on.

Anatomy of Steel

For the needs of the woodworker, three characteristics define steel’s anatomy—grain, structure, and hardness.

Grain

For woodworking hand tools, the grain of the steel is the most important characteristic of a blade. Ordered, repetitive arrangements of iron and alloy atoms in a crystalline structure comprise steel. The crystals can be small and fine or large and coarse. They can be consistent in size (evenly grained) or vary widely, with odd shapes and outsized clusters in among the rest. The steel’s grain affects how finely the blade sharpens and how quickly it dulls. Generally, the finer and more consistent the grain, the more finely a blade sharpens, the slower it dulls, and the better it performs.

Steel Grain

This standardized chart refers to the average grain size within a steel. The numbers range from 00 to 14, with 00 being the largest (about 1/50" [0.5mm]), and 14 the smallest (about 1/10000" [0.003mm]). Manufacturers normally use fine grain size 7 or finer for the steel used in tools.

ASTM Grain Size ASTM grain size number (N)

Average diameter of grain (assumed) as sphere at 1 X (mm)

00

0.51

0

0.36

1

0.25

2

0.18

3

0.125

4

0.090

5

0.065

6

0.045

7

0.032

8

0.022

9

0.016

10

0.011

11

0.008

12

0.006

13

0.004

14

0.003

From the article “Determining Austenite Grain Size of Steels: 4 Methods—Metallurgy” by Jayanti S., on www.engineeringnotes.com.

Grain is a function of the initial quality of the steel used, the alloys added, and how the steel is worked or formed. In addition to the average size of the crystals, the initial quality of the steel may include impurities, called inclusions, which may persist throughout refining. Inclusions add large irregularities to the grain. Irregularities sometimes are used to good effect in swords and perhaps axes, but except for the backing steel on laminated blades, impurities are a detriment to a plane blade. Impurities, when sharpened out to the edge, break off easily, causing chipping and rapid dulling of the edge. The dirtier the steel, the more rapidly it dulls. Fine chipping will not affect the performance of an edge used for chopping wood; depending on the inclusion, it can add tensile, shock-resisting strength to the blade. But for fine woodworking, such as planing a surface, even fine inclusions prevent sharpening the blade to its full potential and shorten the edge’s life.

Alloys change the texture of the grain. They may be part of the steel’s original composition (though usually in small amounts), or added in a recipe to increase the steel’s resistance to shock and heat. Alloys often coarsen the grain, so there is a trade-off. While the edge of an alloy blade may be more durable, especially under adverse working conditions, it may not sharpen as well as an unalloyed blade. To shear wood cleanly, no other attribute of an edge is more important than fineness.

Structure

Structure, the second most important aspect of a woodworking blade, is the result of the change that happens in the original composition of the steel due to heating it and changing its shape with a hammer (or rollers), often called hot work. Heat causes the crystals of the steel to grow. Hammering steel when it is hot causes its crystalline structures to fracture and impedes growth as the grains fracture into smaller crystals. Before being hot-worked, the crystals of steel are randomly oriented and frequently inconsistent in size.

Through forging (repeatedly re-shaping with a hammer while the steel is hot), the grain aligns and knits together in the direction of the metal flow. Proper forging increases grain structure consistency. When exposed at the edge through sharpening, crystals consistent in size and orientation break off one at a time as the blade dulls, rather than breaking off randomly in big clumps. The consistency of the crystals allows for a sharper blade that stays sharp longer.

The Ideal Edge

The edge requirements for cutting different materials vary widely. The most obvious example is the edge required on a kitchen knife. Meat and vegetables are cut by the sawing action of drawing a coarse edge through them. A properly sharpened kitchen knife has what under a microscope would look like a series of small saw teeth, which result from sharpening it with an 800- or 1,200-grit stone. If you are skeptical, sharpen your best kitchen knife like a plane blade with a #8000 stone and try to cut a potato. It will stop cutting halfway through and jam: the knife is sharp enough to cut transparent shavings in wood, but it will not cut halfway through a root vegetable.

Shaving is another one: a razor is somewhat coarsely sharpened so its edge is a series of fine teeth. These “teeth” are then polished with a very fine stone and strop. The teeth snag the hairs and the polish on the teeth allows them to cut the hair. It should be sharper for good woodworking. The lesson is that demonstrations of sharpness using other materials and claims of qualities originating in other trades and uses, such as industry or surgery, are not particularly useful in evaluating a woodworking blade.

Conceptually, for a blade to be perfect for woodworking, it must be possible to polish it down to single-crystal uniformity across its entire edge, with the crystals all lined up neatly, oriented the same direction, all very small and of the same size, equally hard, and tightly bonded to one another so they will not break off. In reality, several types of crystals comprise a cutting edge. The crystals are greatly different in size and hardness and grouped together so they present themselves at the cutting edge in clusters, and so tend to break off in clusters, leaving voids and dull spots. The finest blades, however, have the qualities that enable something approaching the ideal edge.

The techniques used in preparing steel for woodworking tools are hammer forging, drop forging, and no forging. Hammer forging, where repeated hammer blows shape the steel, is the most desirable because it aligns the grain particles (or crystals) of the steel. It is a time-consuming, skillful process and therefore expensive. If improperly done, hammer forging stresses the steel, reducing, rather than increasing, reliability. With the general decline in hand-woodworking skills during the last century, and the increased reliance on power tools, the discriminating market that would appreciate the difference forging makes has shrunk considerably. As a result, hand-forged tools are not commonly manufactured or available in the United States.

Drop forging verges on die cutting. A large, mechanized hammer called the punch drops on the heated blank, smashing it into a die (mold), giving the tool blade its rough shape, often in just one blow. For tools that vary considerably in cross section, this method may be more desirable than grinding or cutting from stock, because the heat of grinding or cutting can cause some minor negative alteration in the grain structure at those areas. Drop forging imparts a marginally more consistent structure than a blade cut or ground from stock. The steel often elongates in the process, resulting in some improvement in the crystalline structure alignment.

Drop forging is preferable to no forging at all, though no forging is an over-simplification, because all tool steel receives some hot work during reshaping. Bar stock is hot-formed by rolling or extruding the ingot into lengths of consistent cross section. The process rearranges the crystalline structure, and the crystals tend to align in the direction of the flow as the steel lengthens. However, the arrangement is not very refined compared with the structure resulting when steel is hot-worked more at the forge. Modern Western chisel blades are frequently drop-forged (though some new premium chisels are being ground from A2 bar stock). Modern Western plane blades, even many after-market premium blades, are usually ground from unworked, rolled stock.

Hardness

Hardness is a major selling point in the advertising of woodworking tools made from various types of steel. However, as explained earlier, grain and structure are the most important factors in the performance of a blade. A plane blade soft enough to shape with a file (for instance, made from a piece of a good, old handsaw blade) will give excellent results if the fineness of its grain allows it to be sharpened well and its structure allows the edge to break off finely and evenly. I knew a boat builder who preferred plane blades made from high-quality saw blades. The blades made it easy for him to file out nicks when his plane hit unexpected metal in the boat structure.

Hardening, Tempering, and Annealing

Steel’s hardness and ductility (the extent to which it can be stretched or bent without breaking) depends on its exact carbon-to-iron ratio and its thermal processing. Different temperatures are associated with different crystal structures, or phases, of the iron and carbon atoms. When steel with a carbon content above 0.4% (the minimum amount required for steel to harden) is heated beyond its critical temperature of around 750°C, it enters what is called the austenite phase. Austenite has a crystal structure that opens to allow the carbon atoms present to combine with the iron.

When austenite is cooled very quickly (by quenching), its structure changes to a needlelike crystalline form called martensite. Martensite locks in the carbon atom, hardening the steel. In this state, the steel is at its hardest, is under a great deal of internal stress, and is quite brittle. The more carbon the steel had to begin with, the more of it will be martensite and the harder it will be. As the carbon goes over 0.8%, however, the steel does not become any harder, but rather grows more brittle. In order for the steel to be useable as a blade, it must be softened to reduce the brittleness to a workable degree. This process is called tempering.

Tempering is a compromise, meant to balance hardness and ductility, and is definitely a judgment call made by the one doing the tempering, based both on experience and the intended use of the blade. To temper a blade, after hardening, the blade is reheated, this time to a lower temperature, perhaps 175°C (depending on the type of steel and the blade’s intended use), and quenched again.

There is a third process, done after the blade has been hot-worked to shape, but before hardening and tempering, and that is annealing. Here the blade is heated red-hot and allowed to cool without quenching. This softens the blade and removes stresses that may have resulted from its being hot-worked. Usually at this point, the blade is then ground to final (or near final) shape—easily done, since it is now soft—and then hardened and finally tempered.

At the other end of the hardness spectrum is carbide, used on power tool blades. Hard and brittle, carbide is unsuitable for the body of the tool blade because it would shatter. While carbide is extremely hard, the particles are also extremely large. Although they do not break off easily, when they do, they break off in clumps so big they are nearly visible to the naked eye. Carbide also cannot be made nearly as sharp as steel. A sharp steel saw or router blade cuts much more cleanly than a sharp carbide blade. Unfortunately, the steel dulls quicker than the carbide, especially when subjected to the glues in plywood and particleboard.

Hardness must be in balance with the intended use of the tool. For instance, high-impact hand tools, such as axes, should be softer than plane blades. Otherwise, the edge fractures quickly under the pounding an ax takes. The blades of fine tools for fine work can be very hard, but if their hardness exceeds the ability of the steel to flex without breaking at the microscopic edge, the tool will be next to worthless.

From Rockwell Hardness Measurement of Metallic Materials by Samuel R. Low, published by the National Institute of Standards and Technology, U.S. Department of Commerce

From Rockwell Hardness Measurement of Metallic Materials by Samuel R. Low, published by the National Institute of Standards and Technology, U.S. Department of Commerce

The Rockwell C (Rc) scale measures the hardness of woodworking blades. This is a unit of measurement determined by the impact of a ball-shaped point into the steel measured in terms of the depth of the resulting impression. The steel in a common grade of handsaw measures around 46–48 Rc, with high-quality Disston saws (at their peak when Disston still owned them) measuring 52–54 Rc. Harder yet, Japanese saws are roughly in the 50–58 Rc range; this is on the cusp of what a file will cut. Decent plane and chisel blades are in the range of 58–66 Rc range—though I would expect a good quality plane blade to be at least 60–62 Rc. Only some finely wrought steels work effectively in the upper-half of this range, principally high-quality hand-forged Japanese blades, and some high-alloy steels. In carbon steels, 66 Rc seems to be a limit above which the edge breaks down too rapidly in use.

FIGURE 1-1. The polished bevel on a cast steel blade reveals the lamination of the backing steel and the cast steel; the color difference is where the two are forge-welded together.

FIGURE 1-2. The color line on the back of this old unpolished rabbet plane blade shows right where the piece of cast steel leaves off and the backing steel takes over for the rest of the blade.

Types of Edge Steel

Steel for hand tool blades can be roughly divided into two categories: carbon steel and alloyed steel. All tool steels contain carbon, which is what makes it possible to harden the metal. Processed from iron and iron ore, carbon steel contains at least 0.5% carbon, and traces of other elements. Alloyed steel is carbon steel with small amounts of other elements added to improve performance under certain conditions and for certain purposes.

Although manufacturers of steel have specific guidelines with regard to the percentages of alloys used in their steels, and each recipe is identified with a name, manufacturers of woodworking tools, at least until recently, usually chose to ignore the nomenclature. They instead choose to give a broadly descriptive or generic term for the steel that may encompass many different steels of widely varying recipes and characteristics, based on how they perceived the market. One example of a descriptive term like this is “tungsten vanadium.” As it turns out, there are quite a few steels with tungsten and vanadium, each widely varying in their percentage—and performance characteristics. This is in direct contrast to contemporary knife makers who are quite specific about which steel they are using in their blades, such as 12C27, 9Cr13CoMoV, or 440C. Recently, hand tool makers have been a little more specific about what type of steel they use for their blades, such as O-1 and A-2, but this is by no means consistent. If you already have a plane and want to know what kind of steel the blade is, you can put it on the grinder and look up the resulting spark pattern; this will give you a good indication of its general type. Of course, you can also use it and see if it performs as you want it to, in which case it may not make any difference what type it is. If you’re buying or replacing a blade, the following information should help.

Alloy Ingredients

Carbon added to iron makes it harder and more wear-resistant. Carbon content of about 0.5% to 0.6% is about the lowest amount found in tool steel. The low-carbon steel is used for hammers, blacksmith tools, etc. A carbon content of about 0.8% makes a steel file hard (about 56–58 Rc). Carbon above that level does not increase the steel’s hardness, but raises its wear resistance. A carbon content of 1.3% is about the highest. The highest-carbon steel is used for razors, engraving tools, etc. A carbon content of about 1.05% is a good average—hard with good wear resistance, and yet not fussy or sensitive to heat.

Tungsten, added in small quantities, can impart a tight, small, and dense grain structure and the ability to attain a keen cutting edge. It also enables steel to retain its hardness at higher temperatures and has a detrimental effect on the steel’s forgeability. A tungsten content of 4% (with 1.3% carbon) is so hard that it is difficult to grind with an emery wheel.

Manganese makes steel sound when first cast into ingots, and easier to hot roll or forge. Practically all tool steel has at least 0.2% of manganese. Steel can contain up to 0.5% manganese before it is considered alloy steel.

Silicon facilitates casting and hot work. It usually is used in combination with manganese, molybdenum, or chromium. All steel has 0.1% to 0.3% silicon. Steel with 0.5% to 2% silicon content is considered an alloy.

Chromium increases the hardness penetration of the steel. A thick bar of plain carbon steel will be hardened to a depth of only 3/16" (5mm) from its face during heat treatment. Adding chromium allows the bar to harden all the way through. Because most woodworking blades are less than 3/8" (9mm) thick, it is not really an issue for woodworkers. Chromium increases the steel’s wear resistance under impact and heat, but does not necessarily increase its hardness. Steel with chromium content of 4% and higher is called high-speed steel.

CARBON STEEL

When manufactured properly, carbon steel sharpens optimally, holds a sharp edge, and resharpens easily—the three basic requirements of a woodworking blade. Its manufacture can be varied slightly to accommodate different woodworking tasks. Many variations exist, based mostly on the quality of ingredients and manufacture, how much it had been hot-worked, and what incidental alloys may be included.

Type

Pros

Cons

White steel

• A forged, very hard, and serviceable Japanese steel capable of getting and keeping a very keen edge, making it ideal for use in difficult-to-plane softwoods and most hardwoods

• While white steel’s long, angular grain structure allows it to take a very keen edge (keener than blue steel), it is less durable in use with abrasive woods than its blue steel cousin

Blue steel

• Both blue steel and white steel get their names from the wrapping paper the mill uses to identify the two. Also forged, blue steel has an addition of tungsten, making it more serviceable in hard and abrasive woods

• Even more expensive than white steel

Cast steel

• A forged, very pure steel

• High quality and highly predictable

• Takes and holds an edge ideally suited to woodworking

• No longer manufactured

• Like blue steel and white steel, the blades always need to be forge-welded (laminated) to a softer, more tensile steel

“Plain” carbon steel

• Very serviceable, but undistinguished blades, unless forged

• Easy to shape and harden

• Perfect for making specific blades for specific tools; try one of the 10xx steels, such as 1095

• Quite a bit of variation in quality, which can be hard to identify until the blade is used

• Usually manufactured with unworked bar stock

ALLOY STEEL