Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: Fox Chapel Publishing

- Kategorie: Lebensstil

- Sprache: Englisch

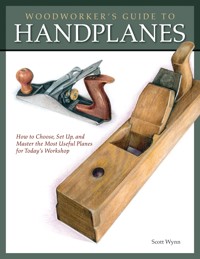

A technically rich analysis and evaluation of every handplane style in the world and how to maintain them for optimum performance.

Das E-Book Woodworker's Guide to Handplanes wird angeboten von Fox Chapel Publishing und wurde mit folgenden Begriffen kategorisiert:

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 557

Veröffentlichungsjahr: 2019

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

ACKNOWLEDGMENTS

To my father, Jerry, who taught me always to watch and listen; and to my daughter, Josephine, who stands on her grandfather’s shoulders watching, listening, and learning— and teaching all of us.

I would also like to acknowledge the untiring support of my partner Kathy Tam, and the helpful guidance of technical editor Rick Mastelli, which made this book possible.

CONTENTS

INTRODUCTION

CHAPTER 1: SMOOTH

What to Use, When, and Why

Understanding is Essential

The Challenge of Grit

CHAPTER 2: SHARP

The Cutting Edge

Beyond Mystique

Anatomy of Steel

The Ideal Edge

Hardening, Tempering, and Annealing

Types of Edge Steel

Alloy Ingredients

CHAPTER 3: PLANE ANATOMY

Tactics for Achieving Best Performance

The Angle of the Blade

Traditional Blade Angles

The Best Blade Angle

Blade Angle and the Task

Custom Blade Angles

Mouth Opening

Chipbreaker

Setting the Chipbreaker

Plane Geometry, a Summary

Bevel Angle

The Correct Bevel Angle

How an Edge Dulls

Shape of the Blade Edge

Length of Plane/Width of Blade

How Flat is “Flat”

Wood Block Planespage 86

CHAPTER 4: BENCH PLANES

Traditional Solutions: the Jack, Jointer, and Smoothing Planes

The Jack Plane

The Fore Plane

Jack Variations

The Jointer Plane

The Correct Blade Shape

Smoothing Planes

CHAPTER 5: THREE MORE PLANES

Strategies for Speeding the Work

The Panel Plane

The Scrub Plane

The Block Plane

Market Block Planes

Adjusting the Throat

CHAPTER 6: STYLES OF PLANES

A Wealth of Traditions

The Bailey Plane

Anatomy of the Bailey-Style Plane

Wood Block Planes

Anatomy of the Wood Block Plane

The Norris Plane

Anatomy of the Norris-Style Plane

Horned Planes

Anatomy of the Horned Plane

Japanese Planes

Anatomy of the Japanese Plane

Chinese Planes

Anatomy of a Chinese Plane

CHAPTER 7: JOINERY PLANES

Tools & Techniques for Making & Fitting Joints

Rabbet Planes

Fillister Planes

Using the Fillister Plane

The Dovetail Plane

Sliding Dovetail

Shoulder Planes

Bull-nose/Chisel Planes

The Router Plane

Using a Bridge Board

Using the Router Plane

Side-Rabbet Planes

The Mortise Plane

CHAPTER 8: PLANES FOR SHAPING WOOD

Specialty Planes that Form and Refine

Compass Planes

The Correct Sole Configuration

Western Versus Japanese Planes for Curves

Hollows & Rounds

Other Shaping Planes

CHAPTER 9: CHOOSING YOUR FIRST PLANES

A Guide to a Suitable Toolkit

First Things First

Beyond the Basics

Razee-Type Wooden Jack Planepage 60

Classic Shoulder Planepage 110

CHAPTER 10: PLANE SETUP

And Tuning Your Plane to Work Right

Preparing the Blade

Preparing the Chipbreaker

Flattening the Back of a Plane Blade

General Techniques for Adjusting the Plane Blade

Setting Up the Bailey/Stanley Plane

Inspect the Plane

Prepare the Blade and Chipbreaker

Bed the Blade Properly

Configure the Sole

Adjust the Mouth

Attend to the Details of the Body and Sole

Attend to the Details of the Grip and Finish

Adjusting the Bailey-Style Plane

Setting Up Wood-body Planes

Inspect the Plane: Old Planes

Tapered Blades

Inspect the Plane: New Planes

Prepare the Blade and Chipbreaker

Bed the Blade Properly

Checking for a Custom Fit

Configure the Sole

Adjusting Wedged, Tapered Blades

Attend to the Details of the Body and Soul

Attend to the Details of the Grip and Finish

Setting Up Chinese Planes

Inspect the Plane

Configure the Sole

Adjust the Mouth

Attend to the Details of the Body and Sole

Attend to the Details of the Grip and Finish

Setting Up Japanese Planes

Inspect the Plane

Tapping Out a Japanese Plane

Prepare the Blade

Prepare and Fit the Chipbreaker

Bed the Blade Properly

Configure the Sole

Adjust the Mouth

Adjusting a Japanese Plane

Attend to the Details of the Grip and Finish

Norris-Style Coffin-Sided Smooth Planepage 89

Setting Up Rabbet Planes

Inspect the Plane

Japanese Skew-Bladed Rabbet Plane

Prepare the Blade

Prepare and Fit the Chipbreaker

Bed the Blade Properly

Configure the Sole

Adjust the Mouth

Attend to the Details of the Body and Sole

Setting Up Fillister and Moving-Fillister Planes

Setting Up Hollows & Rounds

Troubleshooting

CHAPTER 11: SHARPENING PLANE BLADES

A Basic Skill that Leads to Others

Sharpening Fundamentals

Jig Drawbacks

Bevel Shape

Grinding

Sharpening Stones

Using and Maintaining Waterstones

Technique

Sharpening

CHAPTER 12: BENCH WORK

Of Slaves, Dogs, and Deadmen

A Simple Bench

Deadmen and Helper Boys

Bench Dogs

Shooting Board

Dimensioning Stock

Winding Sticks

Preparing the First Face: Scrub and Jack Planes

Continuing With the Jointer Plane

Smoothing the First Face

Planing the Edges and Second Side

Other Handplane Preparatory Work

Shooting an Edge

Techniques for Shooting an Edge

CHAPTER 13: MAKING & USING SHOOTING BOARDS

Invaluable, Often-Overlooked Tools

Types of Shooting Boards

Shooting End Grain

Making a Shooting Board

Classic Simple Moving-Fillister Planepage 105

Long Planepage 55

CHAPTER 14: MAKING & MODIFYING PLANES

Expanding Your Options

Making Traditional Wood-body Planes

Materials

Preliminary Work

Rough-Shaping the Blocks

Fitting the Sole Plate, Cross Pin, and Wedge

Shaping the Smoothing Planes

Handle Shape

Finishing Touches

Making a Japanese-Style Plane

Laying Out a Block for a Japanese Plane

Chiseling the Chipwell, Mouth & Blade Seat

Making Chibi-Kanna

Making a Compass Plane

Hollowing, Rounding & Spoonbottom Planes

Laying Out & Cutting the Mouth Opening for Different Blade Shapes

Fitting a Sole Plate at the Mouth of a Plane

Fitting a Moveable Sole Plate

Fitting a Moveable Sole Plate when Making a Krenov-style Plane

INDEX

These hollowing and rounding planes, basically unchanged since the eighteenth century, are still useful today and can be the fastest way to fair a curve or restore a short section of molding. Above, one plane is used to tune-up its mate.

INTRODUCTION

I cannot think of anyone who has made a shaving with a plane and not been seduced by the sight, sound, and feel of the emerging shaving. It is a tool of enormous satisfaction. However, it is far more than the pleasure of using a plane that makes it important.

The handplane quickly and effectively does things other tools cannot. Power tools have redefined and often supplanted the handplane’s traditional role but not replaced it. And for those who have experienced frustration with the handplane, this knowledge will finally allow you to experience the enormous satisfaction intrinsic to this most essential woodworking tool.

Development peaked during the late-nineteenth century, as great numbers of planes, some of them highly esoteric, were available to woodworkers, professionals, and hobbyists.

Some handplanes were works of art, some mechanical marvels, and some both. Ironically, the mechanization that enabled production of vast numbers of handplanes led to its decline. Mechanization brought mass production and development of woodworking machines, making power tools increasingly available and affordable. The changes reduced demand for handplanes in general and specialty planes in particular. In a culture of mass production, reduced demand often means eventual disappearance, as a product falls below the threshold where development, manufacturing, and distribution costs make economic sense. The economics result in gradual elimination of all but those few models appealing to the broadest market, leaving everything else behind. And typically, the products that do remain are slowly simplified in order to reduce manufacturing costs and further extend market reach, often resulting in a gradual deterioration in the quality of the product.

The gradual decline in the quality and variety of handplanes, and hand tools in general, began around the turn of the twentieth century. For a period, we had the best of both worlds: increased production brought on by the availability of power tools and access to skills nurtured by tradition and the tutelage of a declining apprentice system.

FROM PAST TO PRESENT

With growing industrialization, an emerging global economy, and increasing entrepreneurship creating new fortunes, the newly rich, the established peerage of Europe, and a growing upper-middle class of managers and investors competed to have the first and the best of the latest styles. The quality of production furniture toward the end of the nineteenth century was quite high. While you can argue about the quality of design, the execution was impressive. Mass production made elaborate styles available to a broader clientele than would otherwise have been able to afford them.

However, the world continued to change, and the brief union of patrons, skilled workers, and machine production ended in the Art Deco era with the closing of the shops of Ruhlman, Dunand, and their contemporaries. The shops produced what I believe was some of the best furniture ever made using a combination of machines and hand tools.

The Great Depression brought the end of patronage while World War II and its aftermath brought the mechanization of life. With a need for massive rebuilding and a reduced workforce available in Europe, mechanization seemed the only way to create shelter for those devastated by war, though retention of trade traditions and integration of them into modern life were considerations.

The United States, having built immense production systems during the war, was not about to look back, and handwork was subtly discouraged. Non-essential trades, never fully established as the institutions they were in Europe and elsewhere, and, I believe, a subconscious reminder of the servitude our immigrant fathers had fled, slowly became a curiosity. Training programs, other than the trade unions (and even those declined in quality), lost support and became fewer and farther in-between.

By the time interest in woodworking was renewed—not coincidentally at about the time Fine Woodworking magazine began publication in the mid-1970s, the first of a renaissance of books and magazines on the subject—the economic pressures of mass production and a declining market reduced both the number and quality of hand tools. Only the Bailey/Stanley-style plane and basic hand tools were widely available.

The hand tools were not great quality and little information on setup and use of any of the tools was available. I began woodworking in the late-1960s, picking up what tools I could from the local hardware store, and what tips I could from relatives and a few scattered written sources. The tools were an immediate disappointment. Where were the tools that built the works of art in the museums?

Certainly during 3,000 or more years of woodworking, our predecessors, who did all work by hand, had developed effective ways to maximize their efforts to produce flawless work. The modern tools were not capable of flawless work, and what they could do took backbreaking, hand-blistering effort.

I began to look further afield, searching available sources. In the early-1970s, I drove across the country from my home in Ohio to Berkeley, California, to search out a then-obscure Japanese-tool dealer to look at what were then exotic tools. (The drawings of them in the Whole Earth Catalog looked too bizarre to be real.)

The tools were a revelation—and a validation. Well-made hand tools could be a joy to use and highly productive. I began looking at tools from all woodworking traditions, experimenting with any I could find, identifying strengths and weaknesses, and the work for which they were best suited. I used them daily to make my living.

CHOICES TODAY

The world has changed again. The Information Age has made a galaxy of new tools available. Clearly, I was not alone in my frustration with the quality and availability of tools during that rebirth. Catalogs now offer an array of hand tools from a variety of cultures and times with uses that may be applicable or arcane. Sometimes we have little knowledge of the intended use of these tools, their maintenance, the materials they worked, or the objects they helped to make.

Often, there are only the seller’s descriptions for this information. Handplanes in particular show a disparity in form that suggests they perform tasks differently. However, a systematic look at the anatomy of the handplane and how planes were traditionally used shows that despite differences in form, solutions to woodworking problems have a certain similarity from tool to tool, and culture to culture, from which we can learn.

Today we can choose parts and pieces from a variety of woodworking traditions to fit our style of work—and our style of working wood. Coupled with the tremendous accessibility to machine tools, we have an advantage not enjoyed previously.

To maximize the advantage, woodworkers must consider the type of work they do. Some will derive more benefit from the handplane and hand tools in general. A machine might best accomplish a repeated task (you decide how many justifies automation). Hand tools can efficiently assist or accomplish short runs, one-of-a-kind, prototypes, and variations on a theme. I find one of the main advantages to proficiency with hand tools is fewer limitations in the types of projects I am able to tackle— projects otherwise too small or too big, projects too complex, and projects whose form is evolving even as they’re being produced. Even if you are working in production or large millwork situations, handplane skills can be a godsend.

In addition to extending the range of projects you can tackle, the handplane is demonstrably faster for some tasks, including smoothing small parts. A well-set handplane can smooth a side of a leg, for instance, smoother than 1000-grit sandpaper in two or three strokes, with none of the rounding or waviness you might get with sanding. A few strokes of a handplane can likewise remove the saw marks and tearing you get on end grain. A follow-up of a few strokes with 220-grit sandpaper and you get quick, baby-bottom smoothness. The best tool to remove snipe and power-planer variations is the handplane, as its flat sole flattens the board in removing the snipe. It is fast, and it is accurate.

THE RESULTS

The results you get with a handplane are different from those with sandpaper. Assuming the blade is correctly shaped, a handplaned piece is going to be flatter and straighter than all but the work produced with the best wide-belt sanders. Less expensive wide-belt sanders can leave ripples, as can planers. Belt and orbit sanders leave a gently wavy surface like calm water that shows up especially after applying finish, most noticeably on horizontal surfaces. If you have a flat-grain piece, say in oak or pine, sanding removes more softer spring growth than denser late-season growth, resulting in a gently rippling surface following the grain. This will not happen with a handplane. Power sanding, particularly with the random-orbit sander, tends to slightly round over work in general, but especially smaller pieces, sometimes giving the work a doughy look. Handplaning also provides a better surface for gluing.

Besides the difference in surface quality, there is a subtle but palpable difference in the look and character between pieces shaped and smoothed by edge tools and those prepared by sanding. The crispness and flow suggestive of the sweep of the cutting edge is not present in work abraded to shape. That is an important critical lesson for woodworkers. This is not to say one or another piece would be inferior, but there are differences in the look and feel of the piece. Understanding the difference helps you choose the correct tool.

YOUR HEALTH

Also important to consider in the choice between power tools and handplanes is exposure to dust. Long underestimated, the dangers of dust are now becoming more apparent. The U.S. government has officially identified wood dust as a carcinogen. The modern production shop produces large quantities of it. The one-man shop, with its orbital, belt, stationary, spindle, disk, and thickness sanders can produce choking amounts of it.

The widespread use of abrasives is relatively new, so the long-term effects of inhaling their dust are not fully known, nor are the effects of the many compounds in wood—many of them toxic, allergenic, or simply irritating. These include those associated with any rot-resistant wood and many tropical hardwoods. We know they can cause rashes and other skin reactions. Particles inhaled deeply into the lungs can cause permanent lung damage. The smallest dust particles sanding produces are the most dangerous.

Some particles are so small they pass through the best filters. Read the product specifications— no filtration system, no dust mask is 100% effective. A dust collector can actually make things worse. Anything not collected by the filter (particles from 30 microns to less than 1 micron, depending on your filter) will be blown back into the air, continually suspended, and circulated by the collector until you turn it off. Even if the filtration material in a dust mask were better, no dust mask fits airtight, especially if worn over a beard.

Concern extends beyond the lungs. Long-term dust exposure can cause nasal polyps, which can be pre-cancerous. There also is the very real risk of hearing loss from machine noise. Many woodworkers I know who are my age have suffered some hearing loss.

Therefore, woodworkers should approach sanding with more awareness, and take steps to limit and control their exposure to dust and noise. They should also consider methods beyond a sander to achieve a shape or surface. Perhaps the image of the woodworker quietly planing wood, listening for the sound of a well-cut shaving, the floor littered with (dust-free) streams of shavings, and the bench and tools so free of dust you could wear black clothes to work and leave without a mark, is less romantic and more serious than it would seem. It certainly represents a better quality of life than standing over a screaming, dust-spewing sander for hours on end.

YOUR WALLET

And what about the economics? The handplane can be more cost-effective than sandpaper. Look at the costs of a random-orbit sander. You have the initial investment, less probably than for a good plane, but not cheap. You have the cost of sandpaper: use the sander all day long and you can easily burn through $20 to $30 worth of sandpaper.

Three or four days of that and you just bought yourself a handplane. You have down time when the machine is sidelined for repairs. You are not going to be doing any sanding with it, and when you are not sanding with it, you are not making money.

Then there is the cost of repairs: replace the bearings, brushes, and hook-and-loop pad (which also wears out), and you have just about bought yourself another sander. In addition, no matter what, eventually the machine wears out and must be replaced.

If you were to use a random orbit sander every day, all day, you would wear it out in a year after having the machine repaired twice. Use a handplane all day, every day, and you have worn maybe a half-inch off the blade. You would be able to get another two maybe three years out of that $40 blade.

Assuming you make the correct decisions as to the appropriate tool to use as you work, the efficiency of each tool becomes equal, but the cost of the sander is many times higher.

There are, of course, costs associated with the handplane, but they compare favorably. Once you have set up the plane, which may or may not require much time, maintenance is minimal. Sharpening can be a pain, but with some practice and decent technique, you can be back to work in five minutes or less.

REWARDS

The learning curve for the handplane is higher, but woodworking requires the continual acquisition and advancement of skill. That is the essence of the craft. You do not have to leap into the most challenging uses of the plane right at the beginning. Expand your handplane skills gradually as your skill progresses. The information in this book will greatly shorten the learning curve.

Abrasives are here to stay and are an important part of woodworking. To not use all of the skills and techniques available, or to not acquire the knowledge that will help you choose the appropriate technique and the skill to follow through, limits the scope of your work, creativity, and growth.

Knowledgeable use of both power and hand tools leads to better, more rewarding work, and the handplane, always the premier woodworking instrument, remains one of the most useful tools available. By temperament, and perhaps because of how you see your pieces, you will naturally favor hand tools over power tools, or vice versa, but it is important you make a reasoned decision. The first step to understanding the effectiveness of a technology—in this case woodworking handplanes—is to fully understand the capabilities and limitations of the tool. That is what this book aims to accomplish.

1

SMOOTH

What to Use, When, and Why

Different tools leave different surfaces, discernible by eye, hand, or both. While the differences may be subtle, they still are often immediately recognizable. End users, in particular, can respond quite strongly, even without fully understanding why. Such subtle differences distinguish craftwork from production work and make it sought out by potential buyers, whether consciously or not, and can literally close the sale.

The handplane is unmatched in its ability to get a crisp, clean, clear surface on wood.

Figure 1-1.The grit in sandpaper acts like a series of minute pointed scrapers, removing wood by compression failure at the points of the abrasive. It is a reliable way to smooth wood, but in some ways, it is as if you are using an uneven bed of nails. It leaves a series of erratic uneven grooves across the board, often leaves little balls of wood fiber at the end of the grooves, and tears the edges of the wood pores and fills them with dust. Clarity of the wood’s grain and figure is compromised for reliability.

Understanding is Essential

To get to that level of finesse—of craftsmanship—the use, position, and intended finish of a piece, or parts of a piece, all will have to be considered when deciding on the best tools to use for a project. To make informed decisions, understanding the nature of the different surfaces different tools produce is essential.

The three ways to smooth wood—sanding, scraping, and planing—all leave a different kind of surface.

SANDING

Sanding abrades the surface, leaving a series of irregular microscopic grooves with slightly fuzzy edges. Sandpaper, which consists of randomly distributed abrasive particles of irregular size, shape, and orientation, tears and scrapes the wood fibers. The points and edges of the particles project and wear unevenly, cutting to different depths. The result is most noticeable when starting with coarse sandpaper and then skipping grits, because coarser grits leave deep scratches finer grits will not reach (Figure 1-1).

Sanding also leaves a myriad of microscopic torn fibers hanging onto the surface. And even though you may be meticulous, sanding thoroughly through progressive grits, you still have to sand to a grit finer than 600 to get light to penetrate the torn fibers with enough clarity to bring out the grain of a figured wood.

SCRAPING

Scraping, using the burr turned on the edge or a sharpened blade held at a high angle, tears the wood fibers as well, removing wood essentially by compression failure at the edge of the burr (Figure 1-2).The burr is a relatively blunt cutting edge that establishes a point where compression failure begins, rather than actually cutting or shearing the wood.

Hard tropical woods scrape cleanly, I suppose, because scoring the wood fibers with a blunt edge is more effective on hard, brittle wood. But the softer the species, the less cleanly the burr-edge pulls wood away, often causing the chip to collapse upon itself, while tearing the fibers from the surface being smoothed. The surface of pine, for instance, can be shaped with a scraper, but ends up fuzzy.

The big advantage the scraper has over sandpaper is that on most hardwoods, it removes wood as fast as 60-grit paper and leaves a finish like 400-grit, all with one tool that will probably last a lifetime and cost less than a single package of sandpaper.

Moreover, unlike a plane, it is virtually impossible to get any major tearout with a scraper, though on some woods the resulting fuzziness confirms surface tears. Nor is the scraper unidirectional, as some believe. It cuts better in one direction than the other, though cutting in the wrong direction does not usually result in the disastrous tearout you might get with a plane.

Both sanding and scraping leave the edges of the wood pores ragged, though technically the results are slightly different. With sanding, the last grit used determines the size of the ragged fibers. Whatever the grit, however, torn fibers are plentiful (Figure 1-3). With scraping, the ragged fibers are fewer and longer. In both cases, the fibers lie flat until finish is applied, and then stand up, swollen and stiffened with the finish.

Figure 1-2.A cabinet scraper removes wood by compression failure parallel to the grain at the edge of the burr. While it can give dependable results, a heavy cut can result in erratic failure both in front of and below the edge, snowpiling the chip and reducing the quality of the surface. Making a light cut attains best results.

Figure 1-3.Deep scratches and torn fibers characterize the sanded wood surface. Sanding tears fibers in the surface of wood, while scraping leaves behind fewer ragged fibers that tend to be longer.

Figure 1-4.A handplane removes wood by shearing the fibers right at the point of its thin, sharp edge. Though the results can be less dependable (unless the cut is controlled by the methods described in Chapter 3), the remaining surface is not torn by abrasion or compression failure, revealing the beauty of the wood’s grain and figure.

PLANING

A sharpened plane cuts by shearing the fibers off cleanly. The lower the angle of the cut, the cleaner the shear; the higher the angle, the more the blade scrapes. The shearing cut is clean—the surface is not torn by abrasion or compression failure—and light penetrates the surface structure, refracting through the changes in direction of the wood grain, and revealing the dazzling beauty of the wood’s figure (Figure 1-4).

The surface, however, deserves further consideration. Most woods display wonderful clarity with a little raggedness at the end of the pores (Figure 1-5). The residue rises when applying finish and stiffens when it dries, resulting in a rough surface. Removing the tails to achieve a smooth surface creates a conundrum: in order to get the smoothest surface you must risk compromising clarity by lightly roughing it up.

ADDING FINISH

There are a couple of ways to approach the issue. The first is to consider the planned finish. Penetrating finishes, such as oil, raise the grain less and bring out the figure of the grain more than surface finishes.

On some woods, vigorous application and removal of the oil eliminates the tails, especially if the last step is buffing with a wool rag.

Some woods require rubbing with steel wool after the first or second coat of oil. Steel wool hooks the hanging fibers and pulls them off. Polish some surfaces by rubbing them hard with shavings before applying oil.

I go over broad and/or horizontal surfaces, after planing to a fine finish and applying the first coat of oil, with 1000-grit or finer sandpaper, working either wet or dry for the second coat. The grade of sandpaper I use may vary according to the type of oil I am using and other factors.

Surface finishes, such as varnish or lacquer, do not bring out the figure as well as oil for two reasons: (1) the finish does not penetrate as deeply and (2) light must travel through a thickness of film before striking the wood and bouncing back through again. The clean shear you get from planing is muted, and, therefore, probably less critical. I have also had feedback from finishers that (in one case anyway) the plane left the surface too smooth without enough tooth for the finish to adhere.

To prepare for a heavy surface finish, such as brushed varnish, catalyzed varnish and lacquer, or nitrocellulose lacquer, my general procedure is to remove the machining marks, snipe, and such with a plane. If the plane leaves minor tearout, I remove it with a card scraper. If the project or parts of it (such as shelving) are less sensitive—and especially if the wood is difficult—I may remove the mill marks with a handled scraper, such as the Stanley 80, followed by the card scraper.

A handled scraper is faster than sanding through three or four grits of sandpaper. I follow the planing (or scraping) with a quick, light pass with 220-grit sandpaper to even out any minor irregularities or any traces of the plane or scraper. If the finish is to be shellac, I will follow the planing (and scraping if necessary) with 320- or 400-grit sandpaper. (Follow that procedure for shellac applications except for French polishing, which has its own set of procedures.)

Shellac does not seem to flow out as well as lacquer, even when applied thickly or repeatedly. Shellac seems to benefit from extra sanding. The catalyzed finishes flow out wonderfully and cover a multitude of sins. Unfortunately, catalyzed finishes can also make a closed-pore wood like cherry look like plastic laminate.

Figure 1-5.Scraping often leaves a tail at the end of the wood pore the length of which varies from species to species. Planing also can sometimes result in a tail, depending on the species, but it is usually much smaller. A coat of finish raises and stiffens the tails and other irregularities, making the surface look and feel rough.

FLAT AND SMOOTH

On broad horizontal surfaces, take special care to prepare the surface, no matter what the finish. Once the light glances across the surface, variations in flatness will literally be glaring. Sanding a horizontal surface flat will not yield satisfactory results. Belt sanders and orbital sanders used directly after power planing will result in a surface that looks like a calm pond in a slight breeze when the light reflects across it. I have found most stationary thickness sanders do not give satisfactory results, either. Only the top-end industrial sanders used to finish plywood sheets give anything close to acceptable results.

Hand planing yields flat surfaces, especially if the handplanes used are the correct size for the work. Unfortunately, large surface handplaning is one of the hardest skills to master, though the results can be quite rewarding. Using the tools, techniques, and information presented in this book can accelerate your efforts to acquire these skills. Flattening and smoothing a horizontal surface requires a series of handplanes. If tearout or minor imperfections remain, follow with one or two scrapers. Use a handled scraper, such as a scraping plane (not the Stanley 80) to maintain flatness if tearout is extensive. Use a card scraper over the whole surface for minor tearout. Usually this leaves the surface sufficiently flat and smooth so that, depending on the finish, a light sanding with 220-grit or finer is all that is needed. Often I can even skip this step and have to sand only lightly after the sealer coat of finish.

THE CHALLENGE OF GRIT

The grit size on sandpaper refers to the maximum size contained. On most papers, up to 65% of the abrasive is smaller than the listed grit size, some quite a bit smaller. This means the scratch pattern will be inconsistent, with the listed grit size making deeper scratches than the remaining abrasive. This inconsistent scratch pattern will then have to be reduced by the inconsistent scratch pattern of the next finer grit, and so forth, until the scratch pattern is fine enough not to be easily discerned by the eye or hand. That is why you should not skip grades when sanding. Some of the new premium papers have a more consistent grit size with as much as 95% of the abrasive being of the listed size, so attaining good results should be easier.

If I am not satisfied the surface is flat, I may sand using 220-grit or finer with a half-sheet sanding block to remove any slight ridges or any minor unevenness left between the cuts of the plane or scraper. The ridges or unevenness will not telegraph through visually upon completion of the finish, or physically while sanding between coats.

That is particularly important with a brushed-on varnish finish. The coats do not blend, so cutting through a coat will leave a ring, necessitating removing the finish and starting over. (You can usually avoid cutting through to minor high spots, by either hand sanding without a block, or using a soft block, after the first coat of finish.)

HANDLING EDGES

There is another often-underestimated subtle difference more than one client has pointed out to me. While the handplane leaves a surface whose visual and tactile quality is usually unsurpassed, the surface it leaves on an arris (a corner where two faces come together) usually can be improved.

If you watch clients study pieces of furniture, they will always—consciously or not—run their hand along the edges, making the edges of a piece among its most important features. The edges can clinch the deal—or break it. Knocking the edges off with a handplane will leave a somewhat harsh, unfriendly quality to the piece, even if done with a round-blade chamfer plane. Follow the final touches of a plane with a light sanding to soften the edges, usually with 220-grit sandpaper (or finer if the chamfer was well cut). This will make the all-important edges satisfying to the touch.

SUBTLE DIFFERENCES

So smooth is both visual and tactile, looking and feeling differently in different places, with different results from different tools, and sometimes different results with the same tools—in different woods. How do we use that information effectively?

I have come to a number of conclusions through my experience working with planes. For one, removing a lot of wood by sanding is, in most situations, a poor and inefficient choice. Bring wood as closely as possible to its final shape and finish with a cutting edge—a plane, scraper, or power tool.

After grinding the work with abrasives, sanding with succeeding grits to eliminate the deep scratches from the coarse shaping grit is expensive and time-consuming, and raises excessive fine dust. Sandpaper’s first use was as a final step in polishing the work, and at its most aggressive, removing minor tool marks. I think that remains its best use.

Another important point: Wood shaped by abrasives, rather than by a cutting edge, results in both the shape and surface being different. The differences are subtle, but important. The cut pieces reflect the crispness of the edge used to shape them, and the sweep of the stroke the artisan used to make the cut. Sanded pieces feel and look ground down, reflecting the back-and-forth scrubbing or rotary movement of the abrasives used. The artisan must be aware of the differences and how they will affect the final product.

In summary, on a piece where you want to bring out the figure and texture (grain) of the wood—a piece that is to have no finish or only a light finish such as linseed, lemon, or tung oil, wax, or shellac—smoothing with a clean-cutting plane gives spectacular results and brings out the beauty of the wood.

With some difficult-to-plane woods, however, taking the surface all the way down to a polish with a plane can be demanding and not necessarily efficient. On some special pieces, the extra effort may be worth it. That is an individual decision.

For most work, however, leveling with a plane, smoothing (if required) with a scraper, and a final polishing with sandpaper will be the most efficient procedure. This technique is especially applicable if a heavy surface finish, such as lacquer, brushed varnish, or a catalyzed finish, is to be applied.

2

SHARP

The Cutting Edge

The blade is the heart of any plane. An exotic, expensive hardwood, or marvelously machined bronze and iron may hold it in place, but it is the blade that does the work. If the blade is not up to the job, the plane becomes more of a curious decoration than a valued tool.

The claims tool manufacturers make about their blades are often confusing and contradictory, sometimes invoking near-mystical qualities rather than offering real information. At times, the claims tout qualities applicable to industrial performance and are not meaningful to woodworkers. It was not always this way. Until about World War II, woodworkers had little choice in the material used for blades. Carbon steel was the sole option. The only question was what quality could be afforded. The purchase was often made based on the manufacturer’s reputation. Today’s manufacturers promote new industrial steels and processes as the next best thing. To make matters more difficult, the differences in blade quality are often subtle and hard to discern under many working conditions.

It is the blade that cuts the wood. A plane’s performance will only be as good as the blade it holds. And the characteristics of that blade’s steel must be matched to the work the plane is to do.

Beyond Mystique

Given such confusing information, it is tempting to ignore it, use the blade that comes with the plane, or buy the most expensive blade and hope. Doing so ignores a critical link in the chain of knowledge required to do the best woodworking.

Steel is the interface between wood and woodworker, transmitting your concepts while shaping, smoothing, and transforming the wood. The interface—concentrated at the cutting edge—and the feedback it gives you, provide invaluable input affecting the finish, fit, form, and feeling of the final product as it goes from concept to reality. Understanding the complexities of the steel used for the cutting edge helps you make decisions.

Many woodworkers have only indirect interest in blade steel. Having used a variety of blades over the years and researched the results, I have found cutting edge steel to be complex and possessed of art and nuance. Steel seems to be simple, cold, and aloof, but those qualities disguise its complexity. Mystique surrounds the making of edge steel. Despite several hundred years of industry and science, making steel into blades for cutting wood relies heavily on experience, judgment, and skill.

SHARPENING VERSUS RE-SHARPENING

I use re-sharpen here rather than sharpen because re-sharpen properly evokes the time and repetition involved that the other two words do not. I believe many woodworkers (myself included) do not keep their blades sharp enough, and I want to encourage them to change their habits. Many woodworkers believe sharpening is like cleaning the house: do it once and you are good for the week, or at least for the next few days. However, in reality, if you are using your plane all day, you will need to re-sharpen many times that day. Re-sharpening becomes the nuisance chore that keeps you from doing woodworking until it is done. Easy has a different meaning when it is done twenty times (or more) a week instead of just once.

A blade demonstrates the effort put into its creation—be it a little or a lot. Blade steel— especially forged blade steel—is alive with energy the smith put into making it and the fire used to shape it. A woodworker should understand and appreciate the individuality of blades, learn what they do, and apply the knowledge for greatest effect.

BASIC BLADE CRITERIA

The woodworker needs the edge on the hand-tool blade to do three basic things: get sharp, stay sharp, and re-sharpen easily. The three qualities usually exist in balance with one another. Increasing one probably decreases one or both of the others. In many applications, one quality may be most important, so understanding the strengths and weaknesses of different steels is valuable.

There are additional considerations when selecting a blade. The first is the type of wood being cut. Softwoods and some softer hardwoods prefer an edge that is thin and sharp. Only some steels can get really sharp, to a thinner bevel, and still hold an edge. As the wood gets harder, however, the steel’s toughness becomes more important. Secondly, edge requirements vary with the job. A blade required to remove a lot of wood needs an edge that holds up well under heat build-up and impact.

Anatomy of Steel

The key to understanding edge steel is in its anatomy. I approach the anatomy of steel as a woodworker. The metallurgist or machinist will see things differently. For the needs of the woodworker, three characteristics define steel’s anatomy—grain, structure, and hardness.

STEEL GRAIN

There is a standardized chart that refers to the average grain size within a steel. The numbers range from 00 to 14, with 00 being the largest (about 0.02”), and 14 the smallest (about 0.0001”). Manufacturers normally use fine grain size 7 or finer for the steel used in tools.

GRAIN

For woodworking hand tools, the grain of the steel is the most important characteristic of a blade. Ordered, repetitive arrangements of iron and alloy atoms in a crystalline structure comprise steel. The crystals can be small and fine or large and coarse. They can be consistent in size (evenly grained) or vary widely, with odd shapes and outsized clusters in among the rest. The steel’s grain affects how finely the blade sharpens and how quickly it dulls. Generally, the finer and more consistent the grain, the more finely it sharpens, the slower it dulls, and the better the blade performs.

Grain is a function of the initial quality of the steel used, the alloys added, and how the steel is worked or formed. In addition to the average size of the crystals, the initial quality of the steel may include impurities, called inclusions, which may persist throughout refining. Inclusions add large irregularities to the grain. Irregularities sometimes are used to good effect in swords and perhaps axes, but except for the backing steel on laminated blades, impurities are a detriment to a plane blade. Sharpening impurities out to the edge causes them to break off easily, causing chipping and rapid dulling of the edge. The dirtier the steel, the more rapidly it dulls. This fine chipping will not affect the performance of an edge used for chopping wood. Depending on the inclusion, it can add tensile, shock-resisting strength to the blade. But for fine woodworking, such as planing a surface, even fine inclusions prevent sharpening the blade fully and shorten the edge’s life.

Alloys change the texture of the grain. They may be part of the steel’s original composition (though usually in small amounts), or added in a recipe to increase the steel’s resistance to shock and heat. Alloys often coarsen the grain, so there is a trade-off. While the edge of an alloy blade may be more durable, especially under adverse working conditions, it may not sharpen as well as an unalloyed blade. To shear wood cleanly, no other attribute of an edge is more important than fineness.

STRUCTURE

Structure, the second most important aspect of a woodworking blade, results from changes in the original composition of the steel due to heating it and changing its shape with a hammer (or rollers), often called hot work. Heat causes the crystals of the steel to grow. Hammering steel when it is hot causes its crystalline structures to fracture and impedes growth as the grains fracture into smaller crystals. Before being hot-worked, the crystals of steel are randomly oriented, and frequently inconsistent in size.

Through forging (repeatedly re-shaping with a hammer while the steel is hot), the grain aligns and knits together in the direction of the metal flow. Proper forging increases grain structure consistency. When exposed at the edge through sharpening, crystals consistent in size and orientation break off one at a time as the blade dulls, rather than breaking off randomly in big clumps. The consistency of the crystals allows for a sharper blade that stays sharp longer.

The techniques used in preparing steel for woodworking tools are hammer forging, drop forging, and no forging. Hammer forging, where repeated hammer blows shape the steel, is the most desirable because it aligns the grain particles (or crystals) of the steel. It is a time-consuming, skillful process and therefore expensive. If improperly done, hammer forging stresses the steel, reducing, rather than increasing, reliability. With the general decline in hand-woodworking skills during the last century, and the increased reliance on power tools, the discriminating market that would appreciate the difference forging makes has shrunk considerably. As a result, hand-forged tools are not commonly manufactured or available in the United States.

THE IDEAL EDGE

The edge requirements for cutting different materials vary widely. The most obvious example is the edge required on a kitchen knife. Meat and vegetables are cut by the sawing action of drawing a coarse edge through them. The sawing action of drawing a coarse edge through meat and vegetables cuts them. A properly sharpened kitchen knife has what under a microscope would look like a series of small saw teeth, which result from sharpening it with an 800- or 1200-grit stone. If you are skeptical, sharpen your best kitchen knife with a #8000 stone and try to cut a potato. It will stop cutting halfway through and jam. While the knife is sharp enough to cut transparent shavings in wood, it will not cut halfway through a root vegetable. The lesson is that demonstrations of sharpness using other materials and claims of qualities originating in other trades and uses, such as industry or surgery, are not particularly useful in evaluating a woodworking blade.

Conceptually, for a blade to be perfect for woodworking, it must be possible to polish it down to single-crystal uniformity across its entire edge, with the crystals all lined up neatly, oriented the same direction, all very small and of the same size, equally hard, and tightly bonded to one another so they will not break off. In reality, several types of crystals comprise a cutting edge. The crystals are greatly different in size and hardness and grouped together so they tend to present themselves at the cutting edge, and break off in clusters, leaving voids and dull spots. The finest blades, however, have the qualities that enable something approaching the ideal edge.

Drop forging verges on die cutting. A large mechanized hammer called the punch drops on the heated blank, smashing it into a die (mold), giving the tool blade its rough shape, often in just one blow. For tools that vary considerably in cross-section, this method may be more desirable than grinding or cutting from stock because the heat of grinding or cutting can cause some minor negative alteration in the grain structure at those areas. Drop forging imparts a marginally more consistent structure than a blade cut or ground from stock, because the steel often elongates in the process resulting in some improvement in the crystalline structure alignment.

‘KEEPING THE CUTTING EDGE’ ON DISSTON SAWS

“Disston saw steel was heat treated in the plant and was harder than competitive saws. We rolled our own saw sheets on a sheet mill so we could control the direction of grain within a sheet, enabling us to set the teeth at that hardness without their breaking. Disston saws were of a hardness that read 52–54 on the Rockwell C scale, and competitive saws were 46–48—about 10–15% softer than Disston’s. They did not know the secret of how to roll a new saw sheet so the teeth would not break during setting at that hardness”

From a letter written by Bill Disston, great-grandson of Henry Disston, to Harold Payson, as excerpted in Payson’s book, Keeping the Cutting Edge: Setting and Sharpening Hand and Power Saws (Wooden Boat Books, 1988).

Drop forging is preferable to no forging at all when shaping is done by grinding bar stock. No forging is an oversimplification because all tool steel receives some hot work during reshaping. Bar stock is hot-formed by rolling or extruding the ingot into lengths of consistent cross section. The process rearranges the crystalline structure and the crystals tend to align in the direction of the flow as the steel lengthens.

The arrangement is not very refined compared with the structure resulting when steel is hot-worked further at the forge. Modern Western chisel blades are frequently drop-forged (though some new premium chisels are being ground from A2 bar stock). Modern Western plane blades, even many after-market premium blades, are usually ground from unworked, rolled stock.

HARDNESS

Hardness is a major selling point in the advertising of woodworking tools. However, as explained earlier, grain and structure are the most important factors in the performance of a blade. A plane blade soft enough to shape with a file (for instance, made from a piece of a good old handsaw blade) will give excellent results if the fineness of its grain allows it to be sharpened well and its structure allows the edge to break off finely and evenly. I knew a boat builder who preferred plane blades made from good quality saw blades. The blades made it easy for him to file out nicks when his plane hit unexpected metal in the boat structure.

At the other end of the hardness spectrum is carbide, used on power tool blades. Hard and brittle, carbide is unsuitable for the body of the tool blade because it would shatter. While carbide is extremely hard, the particles are also extremely large. They do not break off easily, but when they do, they break off in clumps so big they are nearly visible to the naked eye. Carbide also cannot be made nearly as sharp as steel. A sharp steel saw or router blade cuts much more cleanly than a sharp carbide blade. Unfortunately, the steel dulls quicker than the carbide, especially when subjected to the glues in plywood and particleboard.

HARDENING, TEMPERING, AND ANNEALING

The hardness and ductility (the extent to which it can be stretched or bent without breaking) of steel depends on its exact carbon-to-iron ratio and its thermal processing. Different temperatures are associated with different crystal structures, or phases, of the iron and carbon atoms. When steel with a carbon content above 0.4% (the minimum amount required for steel to harden) is heated beyond its critical temperature of around 750°C, it enters what is called the austenite phase. Austenite has a crystal structure that opens to allow the carbon atoms present to combine with the iron.

When austenite is cooled quickly (by quenching), its structure changes to a needlelike crystalline form called martensite. Martensite locks in the carbon atom, hardening the steel. In this state, the steel is at its hardest and is under a great deal of internal stress and brittle. The more carbon the steel had to begin with, the more of it will be martensite and the harder it will be. As the carbon goes over 0.8%, however, the steel does not become any harder, but rather grows more brittle. In order for the steel to be usable as a blade, it must be softened to reduce the brittleness to a workable degree. This process is called tempering.

Tempering is a compromise, meant to balance hardness and ductility, and is definitely a judgment call made by the one doing the tempering, based both on experience and the intended use of the blade. To temper a blade, after hardening, the blade is reheated, this time to a lower temperature, perhaps 175°C (depending on the type of steel and the blade’s intended use), and quenched again.

There is a third process, done after the blade has been hot-worked to shape, but before hardening and tempering, and that is annealing. Here the blade is heated red hot and allowed to cool without quenching. This softens the blade and removes stresses that may have resulted from its being hot-worked. Usually at this point, the blade is then ground to final (or near final) shape—easily done, since it is now soft—and then hardened and finally tempered.

Hardness must be in balance with intended tool use. High-impact hand tools should be softer than plane blades. Otherwise, the edge fractures quickly under hard use. Blades for fine work can be very hard, but if their hardness exceeds the ability of the steel to flex without breaking at the microscopic edge, the tool will be next to worthless.

The Rockwell C (Rc) scale measures the hardness of woodworking blades. This is a unit of measurement determined by the impact of a ball-shaped point into the steel, measured in terms of the depth of the resulting impression. Japanese saws (harder than Western saws) are roughly in the 50–58 Rc range. This is on the cusp of what a file will cut. Decent plane and chisel blades are in the range of 58–66 Rc range.

Only some finely wrought steels work effectively in the upper-half of this range, principally high-quality hand-forged Japanese blades, and some high-alloy steels. In carbon steels, Rc 66 seems to be a limit above which the edge breaks down too rapidly in use.

In summary, grain, structure, and hardness are the characteristics of tool steel important to the woodworker using hand tools. Other tool users may emphasize other characteristics—primarily because they are working in other materials or using other methods. The cutting of wood fibers is a very particular application with very specific requirements. The right combination of grain, structure, and hardness—and method— provides good results.

Types of Edge Steel

Steel for hand tool blades can be roughly divided into two categories: carbon steel and alloyed steel. All tool steels contain carbon, which makes it possible to harden the metal. Processed from iron and iron ore, carbon steel contains at least 0.5% carbon and traces of other elements. Alloyed steel is carbon steel with small amounts of other elements added to improve performance under certain conditions and for specific uses.

Steel manufacturers have specific guidelines for nomenclature with regard to the percentages of alloys used. Manufacturers of woodworking tools, have no such guidelines and may at their discretion emphasize or deemphasize any or all included alloys and their relative amounts, depending on what they may think is most marketable. Focusing on the commercial or idiomatic names of blade steel helps clarify the nature of the various steels and reduce confusion.

ALLOY INGREDIENTS

Carbon added to iron makes it harder and more wear resistant. Carbon content of about 0.5% to 0.6% is about the lowest amount found in tool steel. This low-carbon steel is used for hammers, blacksmith tools, etc. A carbon content of about 0.8% makes a steel file hard (about Rc 56-58). Carbon above that level does not increase the steel’s hardness, but raises its wear resistance. A carbon content of 1.3% is about the highest. This highest-carbon steel is used for razors, engraving tools, etc. A carbon content of about 1.05% is a good average—hard with good wear resistance, yet not fussy or sensitive to heat.

Tungsten, added in small quantities, can impart a tight, small, dense grain structure and the ability to attain a keen cutting edge. It enables steel to retain its hardness at higher temperatures but is detrimental to the steel’s forgeability. A tungsten content of 4% (with 1.3% carbon) is so hard it is difficult to grind with an emery wheel.

Manganese makes steel sound when first cast into ingots, and easier to hot roll or forge. Practically all tool steel has at least 0.2% of manganese. Steel can contain up to 0.5% manganese before it is considered alloy steel.

Silicon facilitates casting and hot work. It is usually used in combination with manganese, molybdenum, or chromium. All steel has 0.1% to 0.3% silicon. Steel with 0.5% to 2% silicon content is considered an alloy.

Chromium increases the hardness penetration of the steel. A thick bar of plain carbon steel will be hardened to a depth of only 3/16” (5mm) from its face during heat treatment. Adding chromium allows the bar to harden all of the way through. But, because most hand tool blades are less than ⅜” (10mm) thick, this not really an issue for woodworkers. Chromium increases the steel’s wear resistance under impact and heat, but does not necessarily increase its hardness. Steel with chromium content of 4% and higher is called high-speed steel.

CARBON STEEL

Carbon steel is the longstanding workhorse for manufacturing hand tools for woodworking. Carbon steel’s qualities ideally meet the demands of hand tools for woodworking. When manufactured properly, carbon steel sharpens optimally, holds a sharp edge, and re-sharpens easily—the three basic requirements of a woodworking blade. In addition, its manufacture can be varied slightly to accommodate different woodworking tasks. Many variations exist, based mostly on the quality of ingredients and manufacture, how much it has been hot-worked, and what incidental alloys may be included. The quantity of alloys present may be more than incidental and not mentioned because the hand tool manufacturer has decided to present its steel or allow it to be perceived as carbon steel. Lumped into this general category are a number of types you will encounter commercially. Besides plain high-carbon steel, you will encounter (among others) white steel, blue steel, and cast steel.

White and blue steel are associated with Japanese tools. They derive their name from the color of the identifying paper label applied by the steel maker (usually Hitachi). Both have carbon in the 1% to 1.4% range with 0.1% to 0.2% silica and 0.2% to 0.3% manganese. Blue paper steels additionally have 0.2 % to 0.5% chromium and 1% to 1.5% tungsten, with up to 2.25% tungsten in the super blue steel. The tungsten makes the blue steel harder to forge but increases its wear resistance when cutting difficult woods. On the other hand, adding tungsten widens the critical temperature range needed for hardening the steel, and makes this step a little easier for the blacksmith. In contrast, some white steels are fussy about their hardening temperatures. White steel is easier to sharpen, and takes the keen edge necessary for soft woods.

The difference between white and blue steel is not very obvious. A Japanese woodworker I know makes an enlightened distinction between the two. He describes white steel as having a sharp, angular grain structure, and blue steel as having smaller, rounded grains. This allows the white steel to be sharpened a nuance sharper but under harsh conditions or with difficult woods, white steel’s grain structure breaks off a little quicker and in slightly larger clumps.

For that reason, dealers often recommend blue steel for working hard, abrasive, or difficult tropical woods. I think it is worth noting that Japanese blacksmiths seem to be increasing production of blue steel tools, at least for the U.S. market. The increase may be because blue steel is more tolerant of minor misuse than white steel and workers with less skill are more likely to misuse their tools.

Cast steel, also called crucible steel, is high-quality steel made in small tightly controlled batches, an expensive process developed in Europe and America when producing quality steel was more of a craft than a manufacturing method. Over the years, as production methods improved, ever larger, cheaper, and more consistent batches of steel became possible. As the number of demanding craftsmen dropped, along with their market, particularly during the Great Depression, so, too, did the necessity for cast steel. With World War II and a changing world economy, cast steel all but disappeared and is now produced in only very small quantities (Figure 2-1).

Figure 2-1.A cast steel blade is usually marked Cast Steel or Warranted Cast Steel.

Figure 2-2.A polished bevel on a cast-steel blade reveals the lamination of the two steels; the dark area across the edge of the blade at left is the edge steel, while the lighter area is the softer backing steel. At right is an unlaminated modern blade ground from bar stock.

With its fine grain, cast steel takes and holds an edge far superior to most steels available today. Its qualities seem ideally suited to the demands of fine woodworking as it developed in the West prior to World War II, though its attributes can be appreciated by demanding and discerning craftsman today. I take every opportunity to replace my modern blades with blades made of cast steel.