Erhalten Sie Zugang zu diesem und mehr als 300000 Büchern ab EUR 5,99 monatlich.

- Herausgeber: Fox Chapel Publishing

- Kategorie: Lebensstil

- Sprache: Englisch

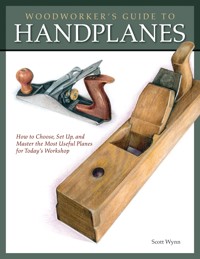

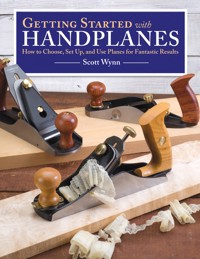

With this book and a well-chosen and correctly maintained set of planes, you will be able to handle any type of wood in every woodworking situation. In an age of power tools the traditional handplane still has a place. Working with handplanes is often quicker, and leaves a cleaner finish. Versatile handplanes can be used as a router, thickness planer, or edger. They can accomplish jobs that would otherwise require expensive, specialized power tools. Author and woodworking instructor Scott Wynn teaches how to choose, set up, maintain, and master the basic variations of this indispensable hand tool. Scott shows how to discern the difference between each style of plane, how to select one that's best for your approach to woodworking, and how to setup and maintain different types. Getting Started with Handplanes is loaded with technically rich diagrams, illustrations, practical advice, and skill building exercises.

Sie lesen das E-Book in den Legimi-Apps auf:

Seitenzahl: 304

Veröffentlichungsjahr: 2017

Das E-Book (TTS) können Sie hören im Abo „Legimi Premium” in Legimi-Apps auf:

Ähnliche

ACKNOWLEDGMENTS

To my father, Jerry, who taught me always to watch and listen; and to my daughter, Josephine, who stands on her grandfather’s shoulders watching, listening, and learning—and teaching all of us.

I would also like to acknowledge the untiring support of my partner Kathy Tam and the helpful guidance of technical editor Rick Mastelli, which made this book possible.

All illustrations by Scott Wynn.

Photos by Rick Mastelli, Scott Wynn, and Jon Deck.

CONTENTS

INTRODUCTION

CHAPTER 1: SMOOTH

What to Use, When, and Why

The Challenge of Grit

CHAPTER 2: SHARP

The Cutting Edge

Sharpening versus Re-Sharpening

Anatomy of Steel

Steel Grain

The Ideal Edge

Disston Saws

Hardening, Tempering, and Annealing

Types of Edge Steel

Alloy Ingredients

Forgeability

CHAPTER 3: TACTICS FOR ACHIEVING BEST PERFORMANCE

Understanding How a Plane Works

The Angle of the Blade

Pitch Angles

Use the Lowest Effective Cutting Angle

Why 45°?

Cutting Angles for Different Woods

Cutting End Grain

Blade Steels for Different Woods

Molding Planes

Mouth Opening

Chipbreaker

Plane Geometry, a Summary

Hard Chipbreakers

Millers Falls Lever Cap

Bevel Angle

The Correct Bevel Angle

Shape of the Blade Edge

How an Edge Dulls

Length of Plane/Width of Blade

Honing a Hollow-Ground Bevel

The Proportion of Length to Width

How Flat is “Flat”

CHAPTER 4: ANATOMY

Understanding How the Stanley/Bailey Plane Works

The Bevel-Down Planes

The Adjusters

The Oiler

The Bevel-Up Planes

CHAPTER 5: BENCH PLANES

Traditional Solutions: the Jack, Jointer, and Smoothing Planes

The Jack Plane

The Fore Plane

The Jointer Plane

Trying, Long, and Jointer

The Correct Blade Shape

Smoothing Planes

The Ideal Edge Shape

Why a Narrow Smoother?

CHAPTER 6: CHOOSING YOUR FIRST PLANES

A Guide to a Suitable Toolkit

First Things First

Adjustable Throat Plates

Beyond the Basics

CHAPTER 7: PLANE SETUP

Setting Up the Bailey/Stanley Plane

Flattening the Back of a Plane Blade

Working Around the Blade-Adjustment Nib

General Techniques for Adjusting the Plane Blade

What Really Happens

A Scraper for Metal

Gauging Straightness

File Mouth Relief

Avoid Distortion

Mouth Going Out of Parallel

Adjusting the Bailey-style Plane

Setting Up a Used #6 Fore Plane

Setting Up the Stanley #60 ½

Adjusting the Throat

Setting Up Rabbet Planes

Setting Up a New Stanley #60 ½

Troubleshooting

Keep Your Eyes on the Prize

Keep the Surface Flat

CHAPTER 8: SHARPENING PLANE BLADES

A Basic Skill that Leads to Others

Bevel Shape

Grinding

Grinding Out a Nick

Grinding on a Sanding Belt

Sharpening Stones

Stone Choices

Diamond Stones

Using and Maintaining Waterstones

Technique

Listening

Sharpening

CHAPTER 9: BENCH WORK

Of Slaves, Dogs, and Deadmen

A Simple Bench

Shooting an Edge

Winding Sticks

Techniques for Shooting an Edge

CHAPTER 10: MAKING & USING SHOOTING BOARDS

Invaluable, Often-Overlooked Tools

Bench Hook versus Shooting Board

INDEX

INTRODUCTION

I cannot think of anyone who has made a shaving with a plane and not been seduced by the sight, sound, and feel of the shaving emerging from the top. It is a tool of enormous satisfaction. However, it is far more than the pleasure of using a plane that makes it important. The handplane quickly and effectively does things other tools cannot. Power tools have redefined and often supplanted the handplane’s traditional role, but have not replaced it. Understanding the handplane (how to set it up, fine-tune it, and adjust and modify its anatomy) and the variety of jobs it handles increases options for work and efficiency and improves results, allowing you to experience the satisfaction this essential tool brings.

THE PLEASURES OF HANDPLANES

A machine might best accomplish a repeated task (you decide how many justifies automation), but hand tools can efficiently assist or accomplish short runs, one-of-a-kind pieces, prototypes, and variations on a theme. I find one of the main advantages to a proficiency with hand tools is fewer limitations in the types of projects I am able to tackle—projects otherwise too small or too big, projects too complex, and projects whose form is evolving even as they’re being produced. Even if you are working in production or large millwork situations, handplane skills can be a godsend.

In addition to extending the range of projects you can tackle, the handplane is demonstrably faster for some tasks, including smoothing small parts. A well-set handplane can smooth a side of a leg, for instance, smoother than 1,000-grit sandpaper in two or three strokes, with none of the rounding or waviness you might get with sanding. A few strokes of a handplane can likewise remove the saw marks and tearing you get on end grain. A follow-up of a few strokes with 220-grit sandpaper and you get quick, baby-bottom smoothness. The best tool to remove snipe and power-planer variations is the handplane, as its flat sole flattens the board in removing the snipe. It is fast, and it is accurate.

The results you get with a handplane are different from those with sandpaper. Assuming the blade is correctly shaped, a handplaned piece is going to be flatter and straighter than all but the work produced with the best wide-belt sanders. Less expensive wide-belt sanders can leave ripples similar to a planer. Belt and orbit sanders leave a gently wavy surface like calm water that shows up especially after applying finish, on horizontal surfaces. If you have a flat-grain piece, say in oak or pine, sanding removes more softer spring growth than denser late-season growth, resulting in a gently rippling surface following the grain. This will not happen with a handplane. Power sanding, particularly with the random-orbit sander, tends to slightly round over work in general, but especially smaller pieces, sometimes giving the work a doughy look. Handplaning also provides a better surface for gluing.

Besides the difference in surface quality, there is a subtle but palpable difference in the look and character between pieces shaped and smoothed by edge tools and those prepared by sanding. The crispness and flow suggestive of the sweep of the cutting edge is not present in work abraded to shape. That is an important and critical lesson for woodworkers. This is not to say one or another piece would be inferior, but there are differences in the look and feel of the piece. Understanding the difference helps you choose the correct tool.

YOUR HEALTH CONCERNS

Also important to consider in the choice between power tools and handplanes is exposure to dust. Long underestimated, the dangers of dust are now becoming more apparent. The U.S. government has officially identified wood dust as a carcinogen. The modern production shop produces large quantities of it. The one-man shop, with its orbital, belt, stationary, spindle, disk, and thickness sanders can produce choking amounts of it. The widespread use of abrasives is relatively new, so the long-term effects of dust inhalation are not fully known, nor are the effects of the many compounds in wood—many of them toxic, allergenic or simply irritating. These include those associated with any rot-resistant wood and many tropical hardwoods. We know they can cause rashes and other skin reactions. Particles inhaled deeply into the lungs can cause permanent lung damage. The smallest dust particles, which sanding produces, are the most dangerous. Some particles are so small they pass through the best filters. Read the product specifications—no filtration system, no dust mask is 100% effective. A dust collector can actually make things worse. Anything not collected by the filter (particles from 30 microns to less than 1 micron, depending on your filter) will be blown back into the air, continually suspended, and circulated by the collector until you turn it off. Even if the filtration material in a dust mask were better, no dust mask fit is airtight, especially if worn over a beard.

Concern extends beyond the lungs. Long-term dust exposure can cause nasal polyps, which can be pre-cancerous. There also is the very real risk of hearing loss from machine noise. Many woodworkers I know who are my age have suffered some hearing loss.

Therefore, woodworkers should approach sanding with more awareness, and take steps to limit and control their exposure to dust and noise. They should also consider methods beyond a sander for achieving a shape or surface. Perhaps the image of the woodworker quietly planing wood, listening for the sound of a well cut shaving, the floor littered with (dust-free) streams of shavings, and the bench and tools so free of dust you could wear black clothes to work and leave without a mark is less romantic and more serious than it would seem. It certainly represents a better quality of life than standing over a screaming, dust-spewing sander for hours on end.

YOUR WALLET

And what about the economics? The handplane can be more cost-effective than sandpaper. Look at the costs of a random-orbit sander. You have the initial investment, less probably than for a good plane, but not cheap. You have the cost of sandpaper: use the sander all day long and you can easily burn through $20 to $30 worth of sandpaper. Three or four days of that and you just bought yourself a handplane. You have downtime when the machine is sidelined for repairs. You are not going to be doing any sanding with it, and when you are not sanding with it, you are not making money. Then there is the cost of repairs: replace the bearings, brushes, and hook-and-loop pad (which also wears out), and you have just about bought yourself another sander. In addition, no matter what, eventually the machine wears out and must be replaced. If you were to use a random orbit sander every day, all day, you would wear it out in a year after having the machine repaired twice. Use a handplane all day, every day, and you have worn maybe a half-inch off the blade. You would be able to get another two maybe three years out of that $40 blade. Assuming you make the correct decisions as to the appropriate tool to use as you work, the efficiency of each tool becomes equal, but the cost of the sander is many times higher.

There are, of course, costs associated with the handplane, but they compare favorably. Once you have set the plane up, maintenance is minimal. Sharpening can be a pain, but with some practice and decent technique, you can be back to work in five minutes or less, depending on the type of plane. The learning curve for the handplane is higher, but woodworking requires the continual acquisition and advancement of skill. That is the essence of the craft. You do not have to leap into the most challenging uses of the plane right at the beginning. Expand your handplane skills gradually as your skill progresses. The information in this book will greatly shorten the learning curve.

Abrasives are here to stay and will continue to be an important part of woodworking. To not use all of the skills and techniques available or to not acquire the knowledge that will help you choose the appropriate technique, and the skill to follow through, limits the scope of your work, your creativity, and growth.

REWARDS

Knowledgeable use of both power and hand tools leads to better, more rewarding work, and the handplane, always the premier woodworking instrument, remains one of the most useful tools available. By temperament, and perhaps because of how you see your pieces, you will naturally favor hand tools over power tools, or vice versa, but it is important you make a reasoned decision. The first step to understanding the effectiveness of a technology—in this case woodworking handplanes—is to fully understand the capabilities and limitations of the tool. That is what this book aims to accomplish.

1

SMOOTH

What to Use, When, and Why

Different tools leave different surfaces, discernable by eye, hand, or both. While the differences may be subtle, they still are often immediately recognizable. End users, in particular, can respond quite strongly, even without fully understanding why. Such subtle differences distinguish craftwork from production work and make it sought out by potential buyers, whether consciously or not, and can literally close the sale.

The handplane is unmatched in its ability to get a crisp, clean, clear surface on wood.

Figure 1-1.The grit in sandpaper acts like a series of minute pointed scrapers, removing wood by compression failure at the points of the abrasive. It is a reliable way to smooth wood, but in some ways it’s like using an uneven bed of nails: it leaves a series of erratic uneven grooves across the board, often leaves little balls of wood fiber at the end of the grooves, and tears the edges of the wood pores and fills them with dust. Clarity of the woods grain and figure is compromised for reliability.

To get to that level of finesse—of craftsmanship—the use, position, and intended finish of a piece, or parts of a piece, all have to be considered when deciding on the best tools to use for a project. To make informed decisions, understanding the nature of the different surfaces different tools produce is essential.

The three ways to smooth wood—sanding, scraping, and planing—all leave a different kind of surface.

SANDING

Sanding abrades the surface, leaving a series of irregular microscopic grooves with slightly fuzzy edges. Sandpaper, which consists of randomly distributed abrasive particles of irregular size, shape, and orientation, tears and scrapes the wood fibers. The points and edges of the particles project and wear unevenly, cutting to different depths. The result is most noticeable when starting with coarse sandpaper and then skipping grits, because coarser grits leave deep scratches finer grits will not reach (Figure 1-1). Sanding also leaves a myriad of microscopic torn fibers hanging onto the surface. And even though you may be meticulous, sanding thoroughly through progressive grits, you still have to sand to a grit finer than 600 to get light to penetrate through the torn fibers with enough clarity to bring out the grain of a figured wood.

SCRAPING

Scraping, using the burr turned on the edge of a sharpened blade held at a high angle, tears the wood fibers as well, removing wood essentially by compression failure at the edge of the burr (Figure 1-2). The burr is a relatively blunt cutting edge that establishes a point where compression failure begins, rather than actually cutting or shearing the wood. Hard tropical woods scrape cleanly, I suppose, because scoring the wood fibers with a blunt edge is more effective on hard, brittle wood. But the softer the species, the less cleanly the burredge pulls wood away, often causing the chip to collapse upon itself, while tearing the fibers from the surface being smoothed. A scraper shapes the surface of pine, for instance, but it ends up fuzzy.

The big advantage the scraper has over sandpaper is that on most hardwoods, it removes wood as fast as 60-grit paper and leaves a finish like 400-grit, all with one tool that will probably last a lifetime and costs the same as a single package of sandpaper. Moreover, unlike a plane, it is virtually impossible to get any major tearout with a scraper, though on some woods, the resulting fuzziness confirms surface tears. Nor is the scraper unidirectional, as some believe. It cuts better in one direction than the other, though cutting in the wrong direction does not usually result in the disastrous tearout you might get with a plane.

Both sanding and scraping leave the edges of the wood pores ragged, though technically the results are slightly different. With sanding, the last grit used determines the size of the ragged fibers. Whatever the grit, however, torn fibers are plentiful. (See Figure 1-3.) With scraping, the ragged fibers are fewer and longer. In both cases, the fibers lie flat until finish is applied, and then stand up, swollen and stiffened with the finish.

Figure 1-2.A cabinet scraper removes wood by compression failure parallel to the grain at the edge of the burr. While it can give dependable results, a heavy cut can result in erratic failure both in front of and below the edge, snowpiling the chip and reducing the quality of the surface. Making a light cut attains best results.

Figure 1-3.Deep scratches and torn fibers characterize the sanded wood surface. Sanding tears fibers in the surface of wood, while scraping leaves behind fewer ragged fibers that tend to be longer.

PLANING

A sharpened plane cuts by shearing the fibers off cleanly. The lower the angle of the cut, the cleaner the shear; the higher the angle, the more the blade scrapes. The shearing cut is clean—the surface is not torn by abrasion or compression failure—and light penetrates the surface structure, refracting through the changes in direction of the wood grain, and revealing the dazzling beauty of the wood’s figure. (See Figure 1-4.)

Figure 1-4.A handplane removes wood by shearing the fibers right at the point of its thin, sharp edge. Though the results can be less dependable (unless the cut is controlled by the methods described in Chapter 3), the remaining surface is not torn by abrasion or compression failure, revealing the beauty of the wood’s grain and figure.

However, in the practical, day-to-day world, even this surface deserves further consideration. Most woods show wonderful clarity with a little raggedness remaining at the end of the pores—a kind of tail or thin fringe to an otherwise cleanly cut pore. (See Figure 1-5.) This residue rises when applying finish and stiffens when the finish dries, resulting in a surface that feels slightly rough. Removing the tails to achieve a smooth surface results in a conundrum: in order to get the smoothest surface you must risk compromising clarity by lightly roughing it up.

ADDING FINISH

There are a couple of ways to approach the issue. The first is to consider the proposed finish. Penetrating finishes, such as oil, raise the grain less and bring out the figure of the grain more than surface finishes. On some woods, vigorous application and removal of the oil with a rag eliminates them, especially if the last step is to buff with a wool rag.

Figure 1-5.Scraping often leaves a tail at the end of the wood pore the length of which varies from species to species. Planing also can sometimes result in a tail depending on the species, but it is usually much smaller. A coat of finish raises and stiffens the tails and other irregularities, making the surface look and feel rough.

Some woods require rubbing with steel wool after the first or second coat of oil. Steel wool hooks the hanging fibers and pulls them off, burnishing, more than abrading, the surface. You can polish some surfaces by rubbing them hard with leftover shavings before applying oil. This method works particularly well with smaller parts, such as legs and stretchers. It is less successful on broad surfaces, especially horizontal ones, as the burnishing tends to be uneven.

I usually go over broad and/or horizontal surfaces after planing, when using oil as a finish, with a very fine grit of sandpaper. If I did a particularly good job on softwood, for instance, I may polish the surface with 1000 grit or finer—or if it looks really good, I may wait until I give it a coat of oil and see if any roughness appears, which I will then remove with 1000+ sandpaper.

On hardwood, especially if I expect to give the surface numerous coats of oil, I may sand first with 400 to 600 grit, depending on how even I was able to plane the surface. After several coats, I’ll sand with 600 to 800 grit and apply more coats. Vertical surfaces don’t need this type of attention; sanding with 400 grit or 0000 steel wool after two or three coats of oil, followed by another coat or two, is sufficient.

Surface finishes, such as varnish or lacquer, do not bring out the figure as well as oil for two reasons: (1) the finish does not penetrate as deeply and (2) light must travel through a thickness of film before striking the wood and bouncing back through again. The clean shear you get from planing is muted, and therefore probably less critical. I have also had feedback from finishers that (in one case anyway) the plane left the surface too smooth without enough tooth for the finish to adhere.

To prepare for a heavy surface finish, such as brushed varnish, catalyzed varnish and lacquer, or nitrocellulose lacquer, my general procedure is to remove the machining marks, snipe, and such with a plane. If the plane leaves minor tearout, I remove it with a card scraper. If the project or parts of it (like shelving) are less sensitive—and especially if the wood is difficult—I may remove the mill marks with a handled scraper, such as the Stanley #80, followed by the card scraper.

A handled scraper is much faster than sanding through three or four grits of sandpaper. I follow the planing (or scraping) with a quick, light pass with 220-grit sandpaper to even out any minor irregularities or any traces of the plane or scraper. If the finish is to be shellac, I will follow the planing (and scraping if necessary) with 320- or 400-grit sandpaper (except for French polishing, which has its own set of procedures).

Shellac does not seem to flow out as well as lacquer, even when applied thickly or repeatedly, and seems to benefit from extra sanding. The catalyzed finishes flow out wonderfully and cover a multitude of sins. Unfortunately, they can also make a closed-pore wood like cherry look like plastic laminate.

FLAT AND SMOOTH

On broad horizontal surfaces, take special care to prepare the surface, no matter what the finish. Once the light glances across the surface, variations in flatness will literally be glaring. Sanding a horizontal surface flat will not yield satisfactory results. Belt sanders and orbital sanders used directly after power planing will result in a surface that looks like a calm pond in a slight breeze when the light reflects across it. I have found most stationary thickness sanders do not give satisfactory results, either. Only the top-end industrial sanders used to finish plywood sheets give anything close to acceptable results.

Hand planing yields flat surfaces, especially if the handplanes used are the correct size for the work. Unfortunately, large surface handplaning is one of the hardest skills to master, though the results can be quite rewarding. Using the tools, techniques, and information presented in this book can accelerate your efforts to acquire these skills. Flattening and smoothing a horizontal surface requires a series of handplanes. If tearout or minor imperfections remain, follow with one or two scrapers. Use a handled scraper, such as a scraping plane (not the Stanley #80) to maintain flatness if tearout is extensive. Use a card scraper over the whole surface for minor tearout. Usually this leaves the surface sufficiently flat and smooth so that, depending on the finish, a light sanding with 220-grit or finer is all that is needed. Often I can even skip this step and have to sand only lightly after the sealer coat of finish.

THE CHALLENGE OF GRIT

The grit size on sandpaper refers to the maximum size contained. On most papers, up to 65% of the abrasive is smaller than the listed grit size, some quite a bit smaller. This means the scratch pattern will be inconsistent, with the listed grit size making deeper scratches than the remaining abrasive. This inconsistent scratch pattern will then have to be reduced by the inconsistent scratch pattern of the next finer grit, and so forth, until the scratch pattern is fine enough not to be easily discerned by the eye or hand. That is why you should not skip grades when sanding. Some of the new premium papers have a more consistent grit size with as much as 95% of the abrasive being of the listed size, so attaining good results should be easier.

If I am not satisfied that planing and scraping have left the surface sufficiently flat, I may sand using 220-grit or finer with a half-sheet sanding block to remove any of the very slight ridges or any minor unevenness left between the cuts of the plane or scraper. This way they will not telegraph through, either visually upon completion of the finish, or physically when sanding between coats. That is particularly important with a brushed-on varnish finish. The coats do not blend with each other but remain separate, so cutting through a coat will leave a ring, necessitating removal of the finish and starting over. (You can usually avoid cutting through to minor high spots, by either hand sanding without a block, or using a soft block, after the first coat of finish.)

HANDLING EDGES

There is another subtle difference that more than one client has pointed out to me. While the handplane leaves a surface whose visual and tactile quality usually is unsurpassed, the surface it leaves on an arris (a corner where two faces come together) usually can be improved. If you watch clients study pieces of furniture, they will always—consciously or not—run their hand along the edges of it, making the edges of a piece among its most important features. The edges can clinch the deal—or break it. Knocking the edges off with a handplane, no matter how finely done, will leave a somewhat harsh, unfriendly quality to the piece, even if done with a round-blade chamfer plane. Follow the final touches with a plane with a light sanding to soften the edges, usually with 220-grit sandpaper (or finer if the chamfer was well cut). This will make the all-important edges satisfying to the touch.

SUBTLE DIFFERENCES

So smooth is both visual and tactile, looking and feeling differently in different places, with different results from different tools, and sometimes different results with the same tools—in different woods. How do we use that information effectively in our day-to-day work? I have come to a number of conclusions through my experience working with planes. For one, removing a lot of wood by sanding is, in most situations, a poor and inefficient choice. Bring wood as closely as possible to its final shape and finish with a cutting edge—either a plane, scraper, or power tool. When the work is ground to shape with abrasives, the surface must be thoroughly sanded with each succeeding grit to ensure the deep scratches from the coarse shaping grit have been eliminated. This is expensive and time consuming, and raises excessive fine dust. Sandpaper’s first use traditionally was as a final step in polishing the work, and at its most aggressive, removing minor tool marks. I think that remains its best use.

Another important point: Wood shaped by abrasives, rather than by a cutting edge, results in both the shape and surface being different. The differences are subtle, but important. Cut pieces reflect the crispness of the edge used to shape them, and the sweep of the stroke the artisan used to make the cut. Sanded pieces feel and look ground down, and reflect the back-and-forth scrubbing or rotary movement of the abrasives used. The artisan must be aware of the differences and how it will affect the final product.

In summary, on a piece where you want to bring out the figure and texture (grain) of the wood—a piece that is to have no finish or only a light finish (such as linseed, lemon, or tung oil), wax, or shellac—smoothing with a clean-cutting plane gives spectacular results and brings out the beauty of the wood. With some difficult-to-plane woods, however, taking the surface all of the way down to a polish with a plane can be demanding and not necessarily efficient. On some special pieces, the extra effort may be worth it. That is an individual decision. For most work, however, leveling with a plane, smoothing (if required) with a scraper, and a final polishing with sandpaper will be the most efficient procedure. This technique is especially applicable if a heavy surface finish such as lacquer, brushed varnish, or a catalyzed finish, is to be applied.

2

SHARP

The Cutting Edge

The blade is the heart of any plane. It may be held in place by exotic, expensive hardwood or marvelously machined bronze or iron, but it is the blade that does the work. If it is not up to the job, the plane becomes more of a curious decoration than a valued tool.

It is the blade that cuts the wood. This beautiful plane’s performance will only be as good as the blade it holds. And the characteristics of that blade’s steel must be matched to the work the plane is to do.

The claims tool manufacturers make about their blades are often confusing and contradictory, sometimes invoking near mystical qualities rather than offering real information. Sometimes the claims tout qualities applicable to industrial performance and are not meaningful to woodworkers. It was easier before: until around World War II the woodworker had little choice in the material for his blades—it would have been carbon steel. The only question was what quality he could afford. The purchase was often based on the manufacturer’s reputation. Today, a wide variety of edge steel is available, with many industrial steels and processes being introduced and promoted as the next best thing. And to make matters worse, blade qualities are often subtle and can be hard to discern under many working conditions—until you start using it for the task it’s not suited for.

Given such an overload of confusing information, it is tempting to ignore it, use the blade that comes with the plane, or buy the most expensive blade and hope price equals quality. Doing so ignores a critical link in the chain of knowledge required to do the best woodworking.

Steel is the interface between wood and woodworker, transmitting your concepts while shaping, smoothing, and transforming the wood. This interface—concentrated at the cutting edge—and the feedback it gives you, provides invaluable input affecting the finish, fit, form, and feeling of the final product as it goes from concept to reality. Understanding the complexities of the steel used for the cutting edge helps you make decisions about the tools and techniques essential for effective, efficient work. This chapter clarifies some of these complexities.

While I know that for the woodworker, blade steel is not wood and is therefore of only indirect interest, having used a variety of blades over the years and having researched the results I was seeing in my day-to-day work, I have found that cutting edge steel is a delightfully complex subject, possessed of art and nuance. At first surmise, steel seems a simple material, cold and aloof. But though its qualities may be more subtle, its character more impenetrable than wood, its apparent coldness and aloofness can disguise great complexity. It becomes understandable that there is so much mystique surrounding the making of edge steel because, despite several hundred years of industry and science, the making of steel into blades for cutting wood remains an inexact science relying heavily on the experience, judgment, and skill of those involved in its production. Like the difference between a mass-produced piece of furniture and a fine handcrafted piece, a blade reveals to those who care to look the amount of effort put into its creation—be it a little or a lot. Like wood, steel has grain, structure, and movement. It can even have a bit of personality or a lack of it. Blade steel—especially forged blade steel—is alive with all of the energy the smith put into making it and the fire used to shape it. A woodworker should understand and appreciate the individuality of each blade, educate himself as he would with any of his tools, and apply this knowledge for greatest effect.

THE BASIC CRITERIA FOR A BLADE

The woodworker needs the edge on the hand tool blade to do three basic things: get sharp, stay sharp, and re-sharpen easily. These three qualities usually exist in balance with one another: increasing one probably decreases one or both of the others. In many applications, however, one quality may be most important, and the right blade choice depends upon understanding the strengths and weaknesses of the different steels—the balance each one strikes among these qualities.

There are additional considerations when selecting a blade, which I mention here and discuss in later chapters. The first consideration is the type of wood being cut. Softwoods and some softer hardwoods prefer an edge that is not only sharp but also thin. Only some steels can get really sharp, to a thinner bevel, and still hold an edge. As the wood gets harder, however, the steel’s toughness becomes more important. Secondly, the edge requirements vary according to the job. A blade required to remove a lot of wood—especially if it is hardwood or tropical hardwood—will need an edge that holds up well under the high heat build-up and impact that accompany vigorous use. The harder the wood, the more important the toughness of the steel.

SHARPENING VERSUS RE-SHARPENING

I use re-sharpen here rather than sharpen or sharpenability because re-sharpen properly evokes the time and repetition involved that the others do not. I believe many woodworkers (myself included) do not keep their blades sharp enough, and I want to encourage them to change their habits. Many woodworkers believe sharpening is like cleaning the house: do it once and you are good for the week, or at least for the next few days. However, in reality, if you are using your plane all day, you will need to re-sharpen many times that day. Re-sharpening becomes the nuisance chore that keeps you from doing woodworking until it is done. Easy has a different meaning when it is done twenty times (or more) a week instead of just once.

Anatomy of Steel

The key to understanding edge steel is in its anatomy. I approach the anatomy of steel as a woodworker. The metallurgist or machinist will see things differently. For the needs of the woodworker, three characteristics define steel’s anatomy—grain, structure, and hardness.

GRAIN

For woodworking hand tools, the grain of the steel is the most important characteristic of a blade. Ordered, repetitive arrangements of iron and alloy atoms in a crystalline structure comprise steel. The crystals can be small and fine or large and coarse. They can be consistent in size (evenly grained) or vary widely, with odd shapes and outsized clusters among the rest. The steel’s grain affects how finely the blade sharpens and how quickly it dulls. Generally, the finer and more consistent the grain, the more finely it sharpens, the slower it dulls, and the better the blade performs.

Grain is a function of the initial quality of the steel used, the alloys added, and how the steel is worked or formed. In addition to the average size of the crystals, the initial quality of the steel may include impurities, called inclusions, which may persist throughout refining. Inclusions add large irregularities to the grain. Irregularities sometimes are used to good effect in swords and perhaps axes, but except for the backing steel on laminated blades, impurities are a detriment to a plane blade. Sharpening impurities out to the edge causes them to break off easily, causing chipping and rapid dulling of the edge. The dirtier the steel, the more rapidly it dulls. Fine chipping will not affect the performance of an edge used for chopping wood; depending on the inclusion, it can add tensile, shock-resisting strength to the blade. But for fine woodworking, such as planning a surface, even fine inclusions prevent sharpening the blade to its full potential, and shorten the edge’s life.

STEEL GRAIN

There is a standardized chart that refers to the average grain size within a steel. The numbers range from 00 to 14, with 00 being the largest (about 1/50"), and 14 the smallest (about 1/10,000"). Manufacturers normally use fine grain size 7 or finer for the steel used in tools.